A kind of polyacrylamide microsphere system and its preparation method and application

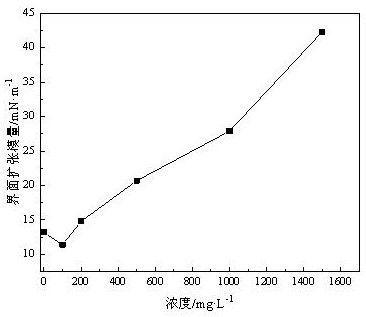

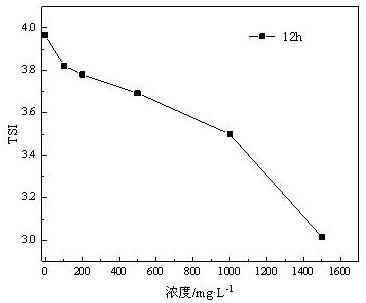

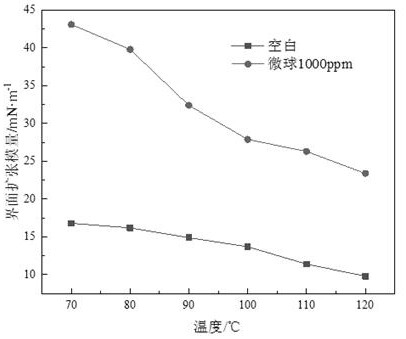

A polyacrylamide microsphere, polyacrylamide technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as insufficient stability of emulsions, and achieve improved expansion modulus and shear modulus, Improve stability, good effect of fluidity control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The second object of the present invention is to provide a method for preparing the polyacrylamide microsphere system described above, the method comprising the following steps:

[0054] Preparation of water phase: Dissolve polymerized monomers, organic salts, cross-linking agents, and polymerization aids in deionized water according to the mass fraction, stir fully until completely dissolved, adjust the pH value to 8-12, mix well and place in a constant temperature water bath Stabilize to the temperature required for polymerization, ready for use;

[0055] Preparation of the initiator solution: dissolve the oxidizing agent and the reducing agent in deionized water according to a certain mass fraction; dissolve the azo compound in 1% to 10% non-polar solvent for emulsification; preferably, the oxidizing agent and the reducing agent in the initiator The ratio of reducing agent is 0.5~2:1;

[0056] Preparation of oil phase: Dissolve emulsifier and co-emulsifier in non-po...

Embodiment 1

[0066] The preparation method of the polyacrylamide microsphere system comprises the following steps:

[0067] (1) Preparation of the aqueous phase:

[0068] Add 270g of deionized water to the container, add 150g of polymerized monomer acrylamide, 37.5g of 2-acrylamido 2-methylpropanesulfonic acid, and use a cantilever stirrer at 400rpm under the protection of nitrogen at a pressure of 0.3MPa. Continue to stir at high speed until completely dissolved. Continue to add 3g of sodium citrate, 0.12ml of N,N-methylenebisacrylamide aqueous solution with a concentration of 0.5g / 100mL, 0.06g of azobisisobutylamidine dihydrochloride, 0.4g of urea, 0.2g of DTPA, 0.6mL of sodium bisulfite aqueous solution with a concentration of 0.5g / 100mL, stir well until completely dissolved, use sodium hydroxide to adjust the pH value of the solution to 9.0, continue to add deionized water to replenish the system quality to 600g, and transfer to a 45°C water bath Set aside.

[0069] (2) Preparation ...

Embodiment 2

[0086] The preparation method of the polyacrylamide microsphere system comprises the following steps:

[0087] (1) Preparation of the aqueous phase:

[0088]Add 270g of deionized water into the container, add polymerized monomers (150g of acrylamide, 37.5g of acrylic acid) into the container, and use a cantilever stirrer under the protection of nitrogen at a pressure of 0.3MPa at a speed of 400rpm to continue stirring until completely dissolved. Continue to add 3.5g of sodium citrate, 0.12ml of N,N-methylenebisacrylamide aqueous solution with a concentration of 0.5g / 100mL, 0.06g of azobisisobutylamidine dihydrochloride, 0.4g of urea, 0.2g EDTA, 0.6mL sodium bisulfite aqueous solution with a concentration of 0.5g / 100mL, stir well until completely dissolved, adjust the pH value of the solution to 9.0 with sodium hydroxide, continue to add deionized water to supplement the system quality to 600g, transfer to 55 ℃ water bath for use.

[0089] (2) Preparation of oil phase:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com