Core-shell type nanosphere flame retardant and preparation method thereof

A technology of nano-microspheres and flame retardants, applied in the field of core-shell nano-microspheres flame retardants and their preparation, can solve the problems of poor compatibility between flame retardants and polymers, poor flame retardant effect, etc., and achieve improved Mechanical properties and flame retardant efficiency, improved physical and chemical activity, good char formation and smoke suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

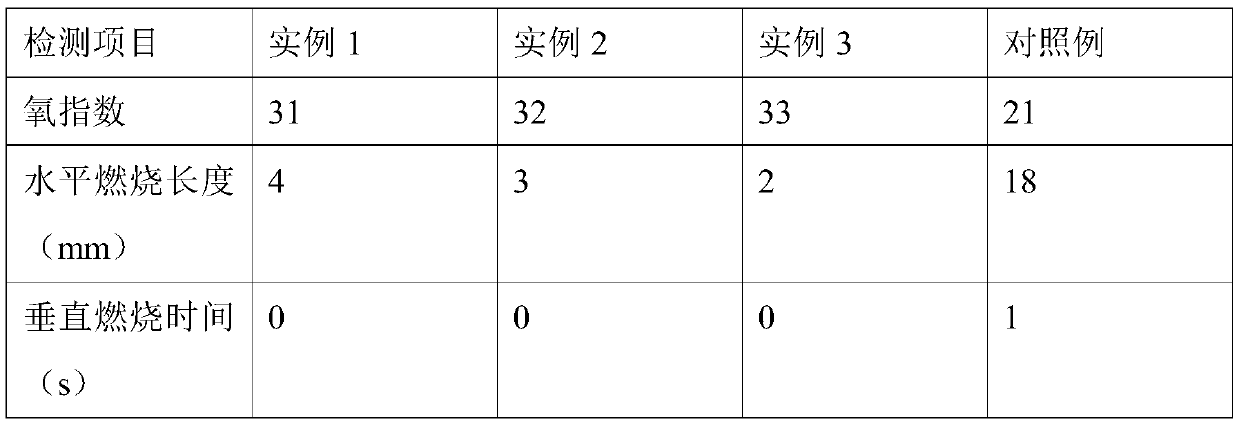

Examples

preparation example Construction

[0044] (1) Preparation of suspension:

[0045] Put the sodium silicate solution with a mass fraction of 30% into a beaker, adjust the pH to 5-6 with a concentration of 1mol / L hydrochloric acid, stir and react for 10-15 minutes, heat up to 110-120°C, and continue to stir and react for 1-2 hours , to obtain a suspension;

[0046] (2) Preparation of precursor solution:

[0047] The suspension obtained above, the sodium hydroxide solution with a mass fraction of 5% and the sodium metaaluminate solution with a mass fraction of 30% were mixed and stirred according to a mass ratio of 2:1:8 to obtain a precursor solution;

[0048] (3) Preparation of reaction filter residue:

[0049] Move the precursor solution obtained above into a high-pressure hydrothermal kettle, then add potassium thiocyanate with a mass of 2% of the precursor solution and a citric acid solution with a concentration of 10% of the quality of the precursor solution to 0.5mol / L in the high-pressure hydrothermal ket...

example 1

[0054] (1) Preparation of suspension:

[0055] Put the sodium silicate solution with a mass fraction of 30% into a beaker, adjust the pH to 5 with hydrochloric acid with a concentration of 1 mol / L, stir and react for 10 minutes, heat up to 110°C, and continue to stir and react for 1 hour to obtain a suspension;

[0056] (2) Preparation of precursor solution:

[0057] The suspension obtained above, the sodium hydroxide solution with a mass fraction of 5% and the sodium metaaluminate solution with a mass fraction of 30% were mixed and stirred according to a mass ratio of 2:1:8 to obtain a precursor solution;

[0058] (3) Preparation of reaction filter residue:

[0059] Move the precursor solution obtained above into a high-pressure hydrothermal kettle, then add potassium thiocyanate with a mass of 2% of the precursor solution and a citric acid solution with a concentration of 10% of the quality of the precursor solution to 0.5mol / L in the high-pressure hydrothermal kettle, and ...

example 2

[0064] (1) Preparation of suspension:

[0065] Put the sodium silicate solution with a mass fraction of 30% into a beaker, adjust the pH to 6 with hydrochloric acid with a concentration of 1mol / L, stir and react for 13 minutes, heat up to 115°C, and continue to stir and react for 2 hours to obtain a suspension;

[0066] (2) Preparation of precursor solution:

[0067] The suspension obtained above, the sodium hydroxide solution with a mass fraction of 5% and the sodium metaaluminate solution with a mass fraction of 30% were mixed and stirred according to a mass ratio of 2:1:8 to obtain a precursor solution;

[0068] (3) Preparation of reaction filter residue:

[0069] Move the precursor solution obtained above into a high-pressure hydrothermal kettle, then add potassium thiocyanate with a mass of 2% of the precursor solution and a citric acid solution with a concentration of 10% of the quality of the precursor solution to 0.5mol / L in the high-pressure hydrothermal kettle, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com