Novel high-flux filtering device and using method thereof

A filtration device and high-throughput technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of low cross-flow filtration permeation flux rate, small effective water filtration area, and ineffectiveness Save energy consumption and other issues, achieve the effect of reducing power and flow, reducing operating costs, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

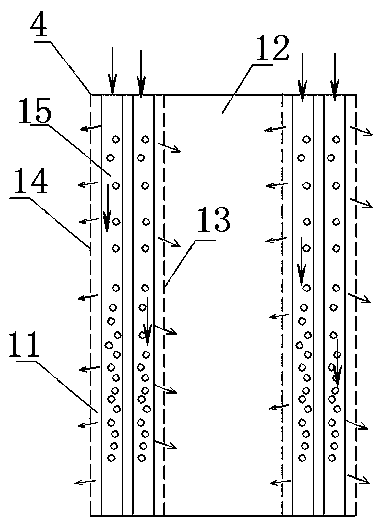

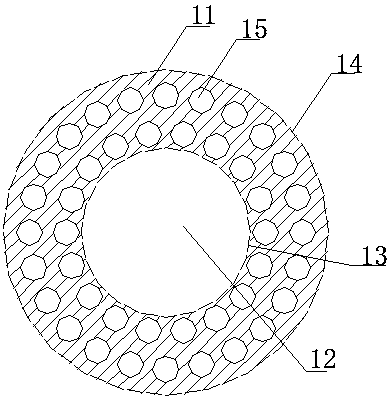

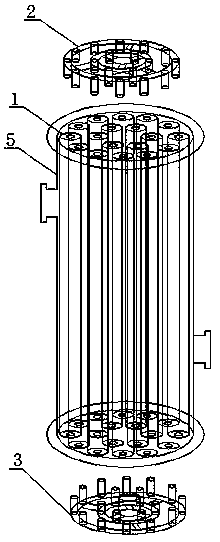

[0041] The support body 4 adopts a cylindrical structure, and the center of the support body 4 is provided with a cylindrical inner cavity channel 12 along the axial direction, and the cross-sectional area of the inner cavity channel 12 accounts for 1 / 5 of the cross-sectional area of the support body 4. The support layer 11 is formed between the layers, the support layer 11 is made of moissanite, the filtration accuracy of the support layer 11 is 10um, the inner membrane layer 13 and the outer membrane layer 14 of the support layer 11 are made of moissanite, and the inner membrane layer 13 is made of moissanite. and the outer membrane layer 14 have a filtration accuracy of 300nm; the support layer 11 is provided with four layers arranged in the axial direction, and the raw material liquid filtration channels 15 are distributed in an asymmetric structure. The cross-sectional area of 15 accounts for 1 / 8 of the cross-sectional area of the support body 4 .

[0042] The noz...

Embodiment 2

[0046] The support body 4 adopts a cylindrical structure, and the center of the support body 4 is provided with a polygonal (6-sided structure) inner cavity channel 12 along the axial direction. The cross-sectional area of the inner cavity channel 12 accounts for 1 / 4 of the cross-sectional area of the support body 4. A support layer 11 is formed between the channel 12 and the outer layer of the support body 4. The support layer 11 is made of a mixture of alumina and zirconia. The filtration accuracy of the support layer 11 is 1um. The layer 14 is made of alumina and zirconia, and the filtration precision of the inner membrane layer 13 and the outer membrane layer 14 is 400nm; the support layer 11 is provided with three layers along the axial direction, and the raw material liquid filtration channels 15 are distributed in an asymmetric structure , The raw material liquid filtering channel 15 adopts a polygonal (6-sided structure) structure, and the cross-sectional area of ...

Embodiment 3

[0051] The support body 4 adopts a cylindrical structure, and the center of the support body 4 is provided with a triangular inner cavity channel 12 along the axial direction. The cross-sectional area of the inner cavity channel 12 accounts for 1 / 3 of the cross-sectional area of the support body 4. A support layer 11 is formed between the layers, and the support layer 11 is made of rubber, plastic or rubber-plastic composite material. The filtration precision of the support layer 11 is 50um, and the inner membrane layer 13 and the outer membrane layer 14 of the support layer 11 are made of aluminum oxide , zirconium oxide and titanium oxide, the filtration accuracy of the inner membrane layer 13 and the outer membrane layer 14 is 500nm; the support layer 11 is provided with two layers along the axial direction, and the raw material liquid filtration channels 15 are distributed in an asymmetric structure, The raw material liquid filtering channel 15 adopts a triangular struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com