Spraying device for environment-friendly waste treatment

A technology for waste treatment and spraying device, which is applied in the direction of combination device, dispersed particle separation, chemical instrument and method, etc., can solve the problems of heat loss of exhaust gas, energy waste, and decrease of exhaust gas purification effect, so as to improve the purification effect and efficiency, Avoid waste of resources and expand the effect of spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

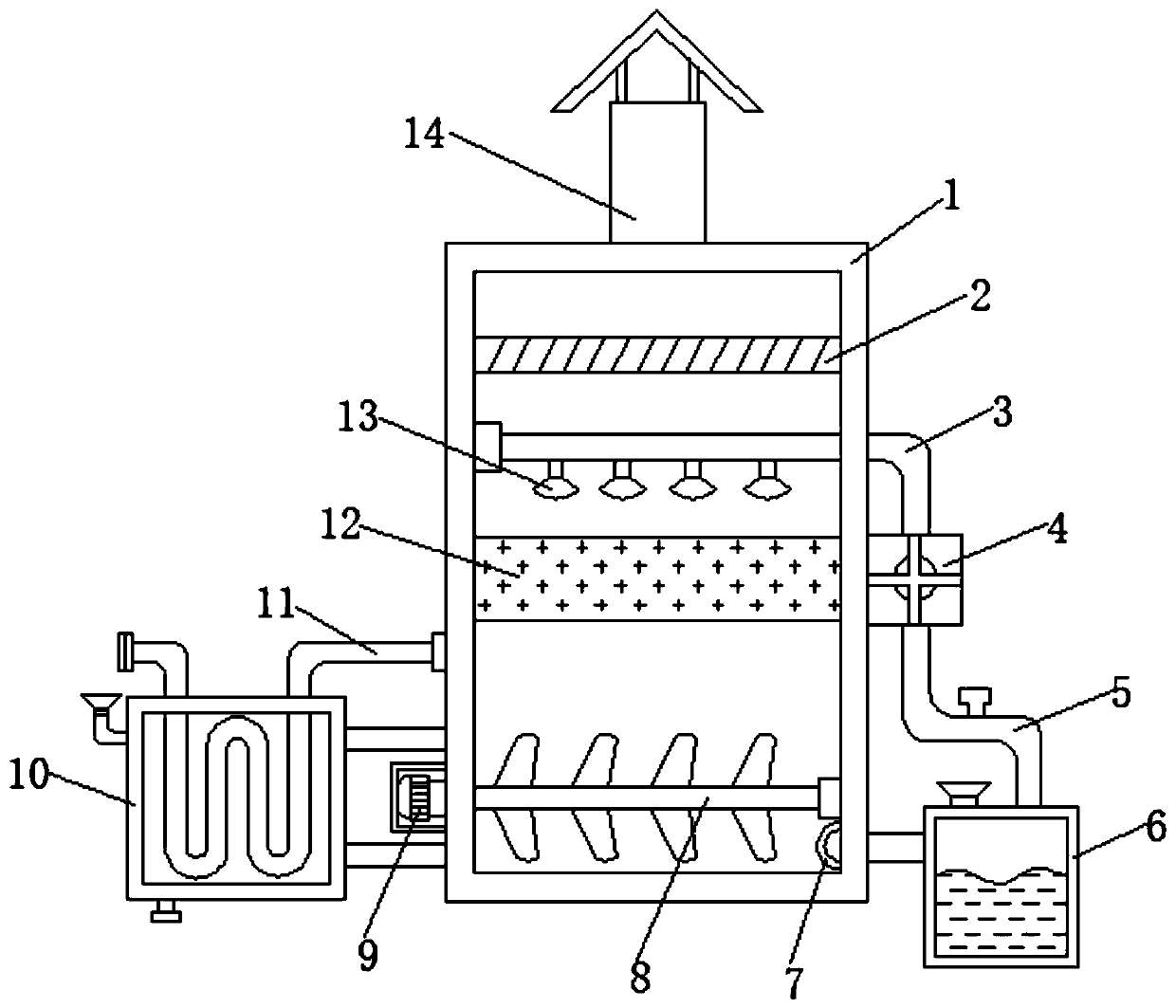

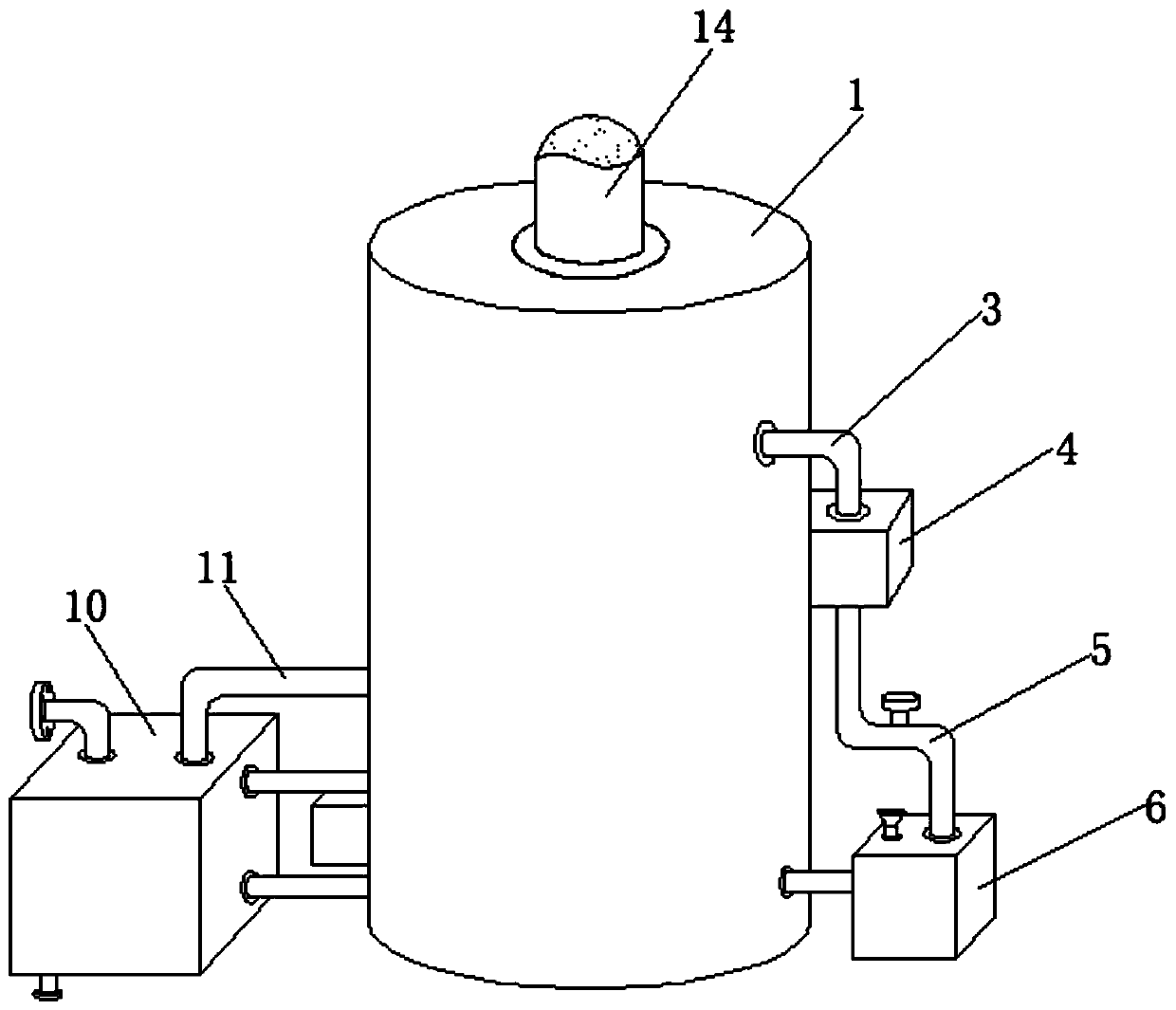

[0026] refer to Figure 1-2 , a spraying device for environmental protection waste treatment, comprising a box body 1, a fixed column is connected to the outer wall of one side of the box body 1 by bolts, and a water storage tank 10 is connected to the outer wall of one end of the fixed column by bolts, and the top inner wall of the water storage tank 10 is inserted An air inlet pipe 11 is connected, and one end of the air inlet pipe 11 extends to the inside of the tank body 1, and one end of the tank body 1 is connected with a liquid return pipe, and one end of the liquid return pipe is connected with a liquid storage tank 6, and the liquid storage tank 6 The top outer wall is plugged with a connecting pipe 5, and one end of the connecting pipe 5 is plugged with a water pump 4, the top outer wall of the water pump 4 is plugged with a nozzle pipe 3, and the bottom outer wall of the nozzle pipe 3 is plugged with equidistant nozzles 13.

[0027] Wherein, one side outer wall of b...

Embodiment 2

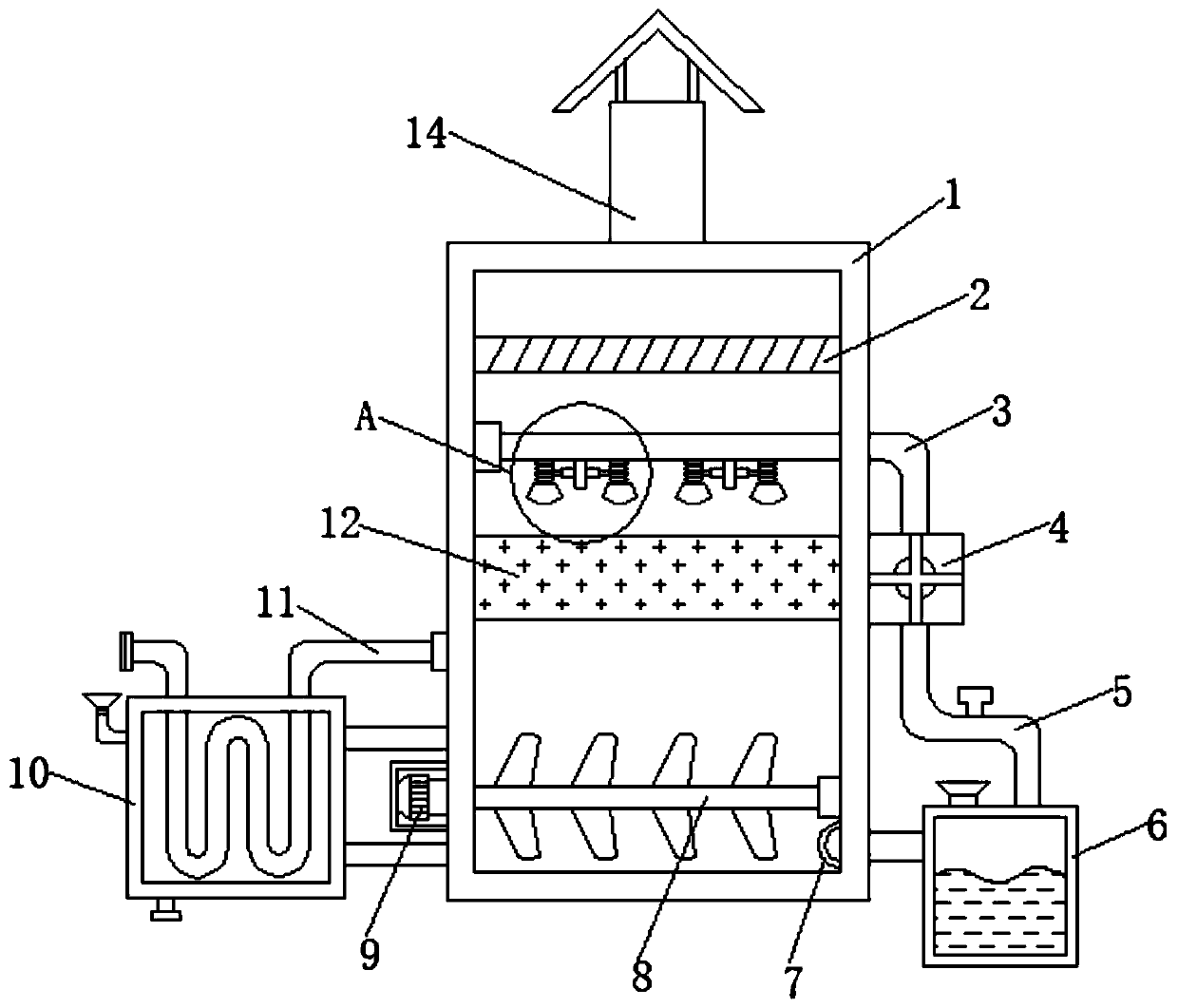

[0030] refer to Figure 3-4 , a spray device for environmental protection waste treatment. Compared with Embodiment 1, the outer wall of the bottom of the nozzle 3 is welded with a fixed plate 17, and the outer walls on both sides of the fixed plate 17 are connected with electric push rods 16 by bolts. , The outer wall of one end of the electric push rod 16 is provided with a bellows 15 .

[0031] Working principle: When in use, people connect the intake pipe 11 with the industrial exhaust gas discharge pipe, and then through the water storage tank 10, a large amount of heat carried in the exhaust gas in the intake pipe 11 can be absorbed to avoid waste of resources caused by direct heat discharge. The cross-section of 11 is serpentine, which can prolong the contact time between waste gas and water and improve the effect of waste heat recovery. Then people start the water pump 4, and the water pump 4 pumps the absorption liquid into the nozzle 3 and sprays it out from the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com