Volume control type rotary compressor and freezing circulation device

A technology of rotary compressor and capacity control, which is applied in the direction of rotary piston machines, rotary piston pumps, components of pumping devices for elastic fluids, etc. It can solve the problems of sliding vane groove wear and energy loss, and achieve sliding Small loss, small wear, simple switching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, only used to explain the present invention, and should not be construed as a limitation of the present invention.

[0051] Implementation status 1:

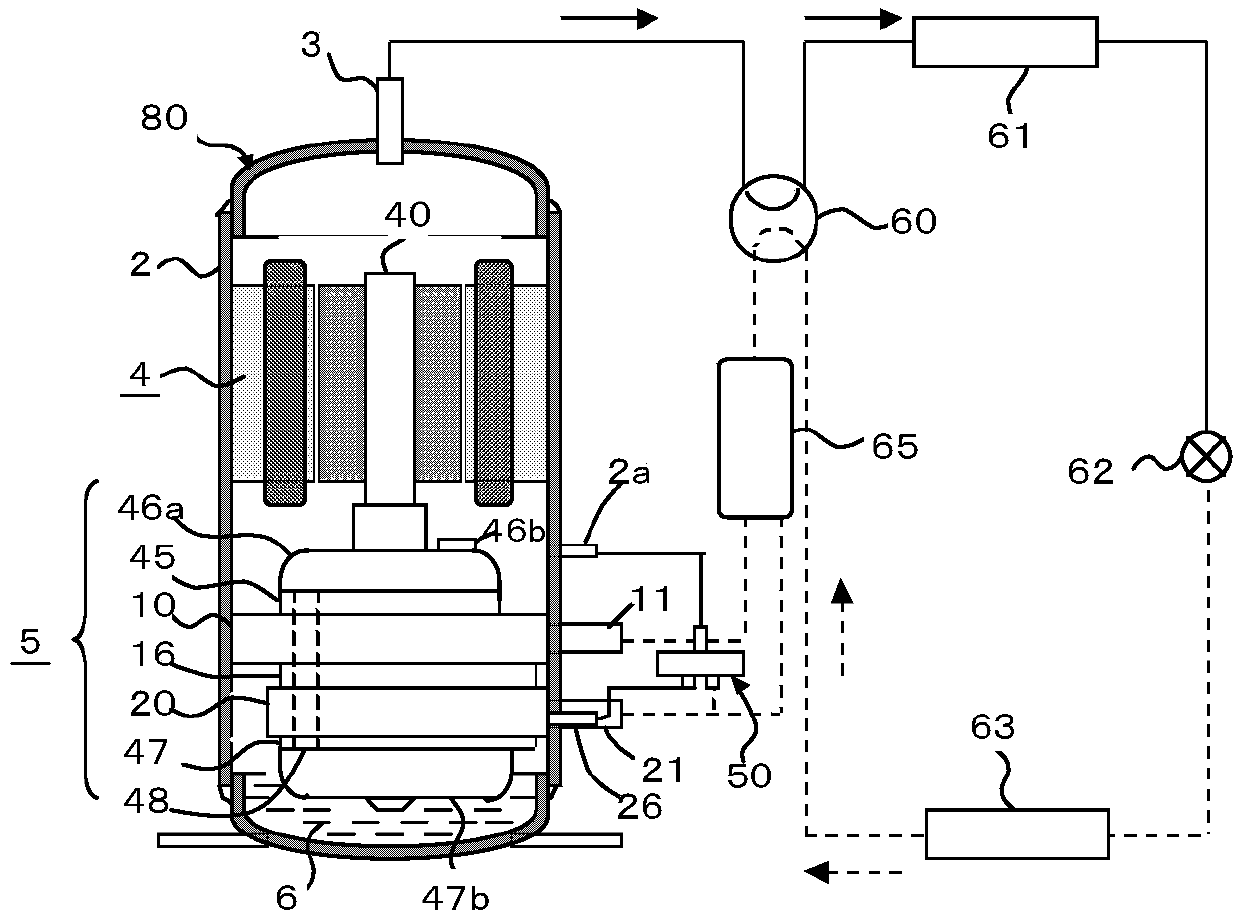

[0052] figure 1 Shown is a 2-cylinder capacity-controlled rotary compressor 80 and a refrigeration cycle system of an air conditioner connected to the compressor 80 . 2 Cylinder capacity-controlled rotary compressor 80 is mainly composed of a variable-frequency electric motor 4 fixed on the inner periphery of the closed casing 2 and a compressor structure 5 driven by the electric motor 4 with a capacity control function. The bottom of the casing 2 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com