Sealing member

A technology for sealing parts and walls, which is applied in the direction of engine sealing, engine sealing device, engine components, etc., can solve the problems of reduced sealing function, large wear and large sliding loss of side seals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

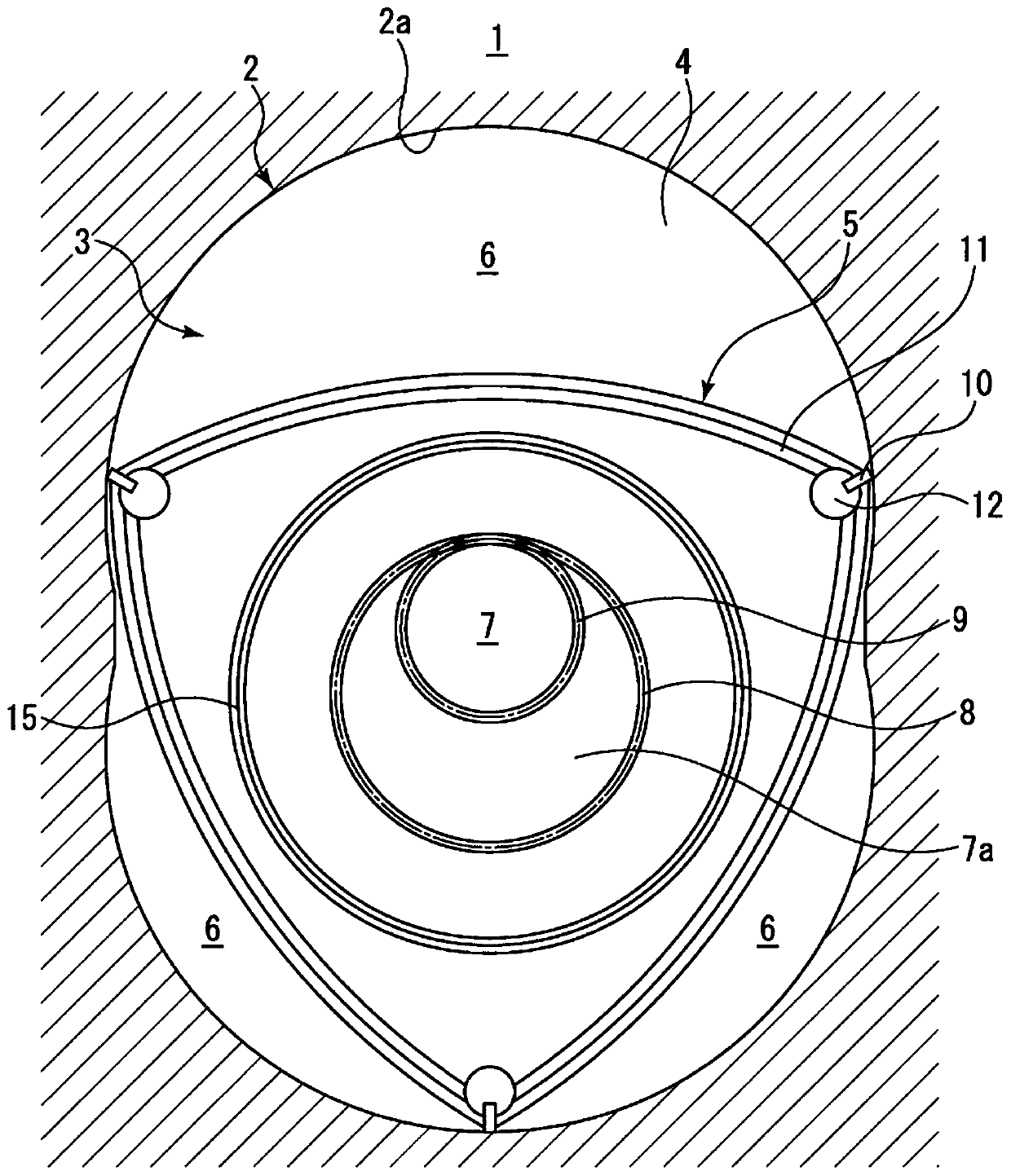

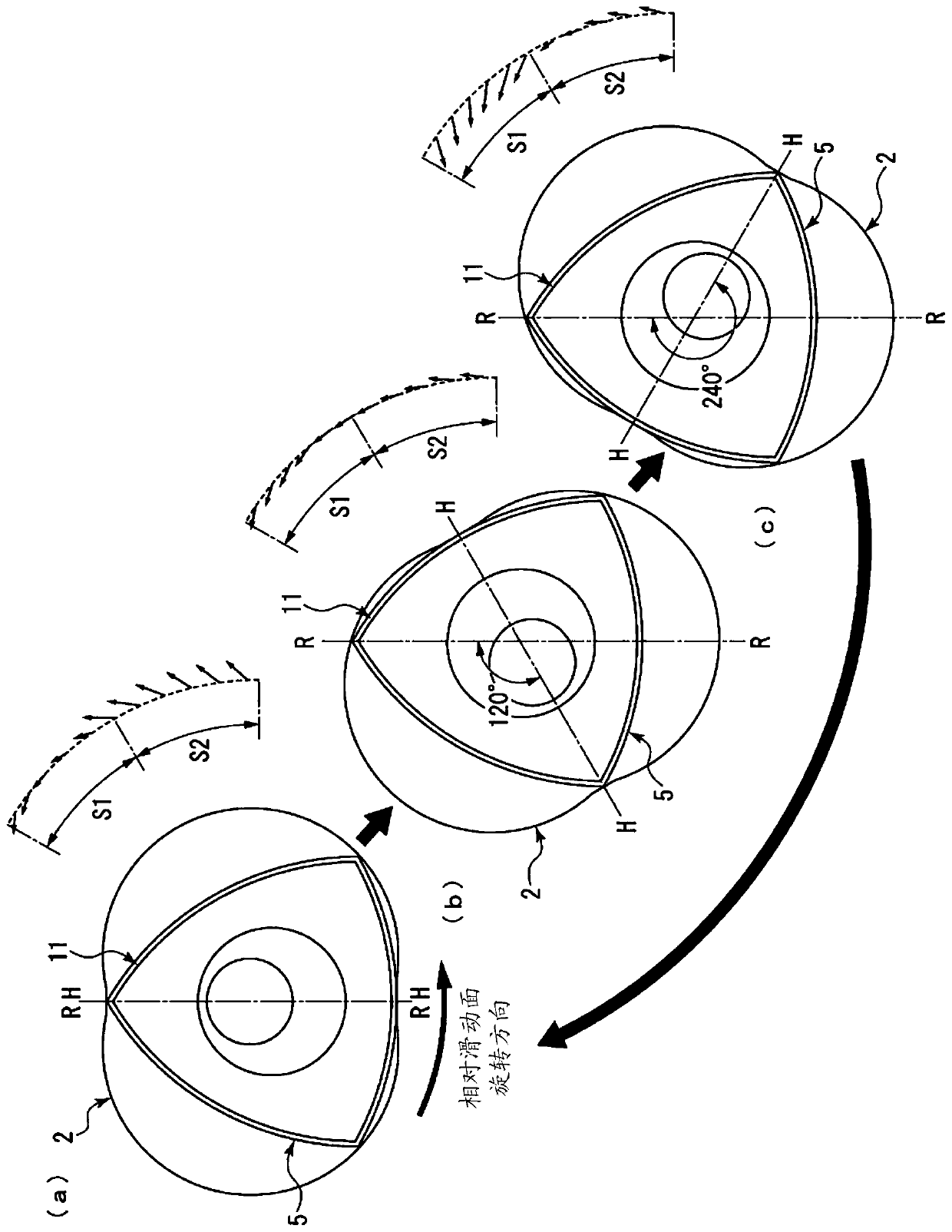

[0039] combine Figure 1 to Figure 4 , the sealing member of the present invention will be described. In addition, in this embodiment, as the sealing member of the present invention, a side seal that seals between the side surface of the rotor for a rotary engine and the side casing will be described as an example.

[0040] exist figure 1 Among them, the rotary engine 1 has: a casing and a rotor 5 (rotary body of the present invention), wherein the casing is clamped from both axial sides by the rotor casing 2 having the inner peripheral wall 2a of the double-arc epicycloid curve shape The rotor case 2 is composed of a pair of side cases 3 (side walls of the present invention), and the rotor 5 is accommodated in the housing chamber 4 defined by the rotor case 2 and the side cases 3 and has a triangular shape. The rotary engine 1 It also has three working chambers 6 defined by the outer peripheral wall of the rotor 5 and the inner peripheral wall 2a of a cycloidal shape.

[...

Embodiment 2

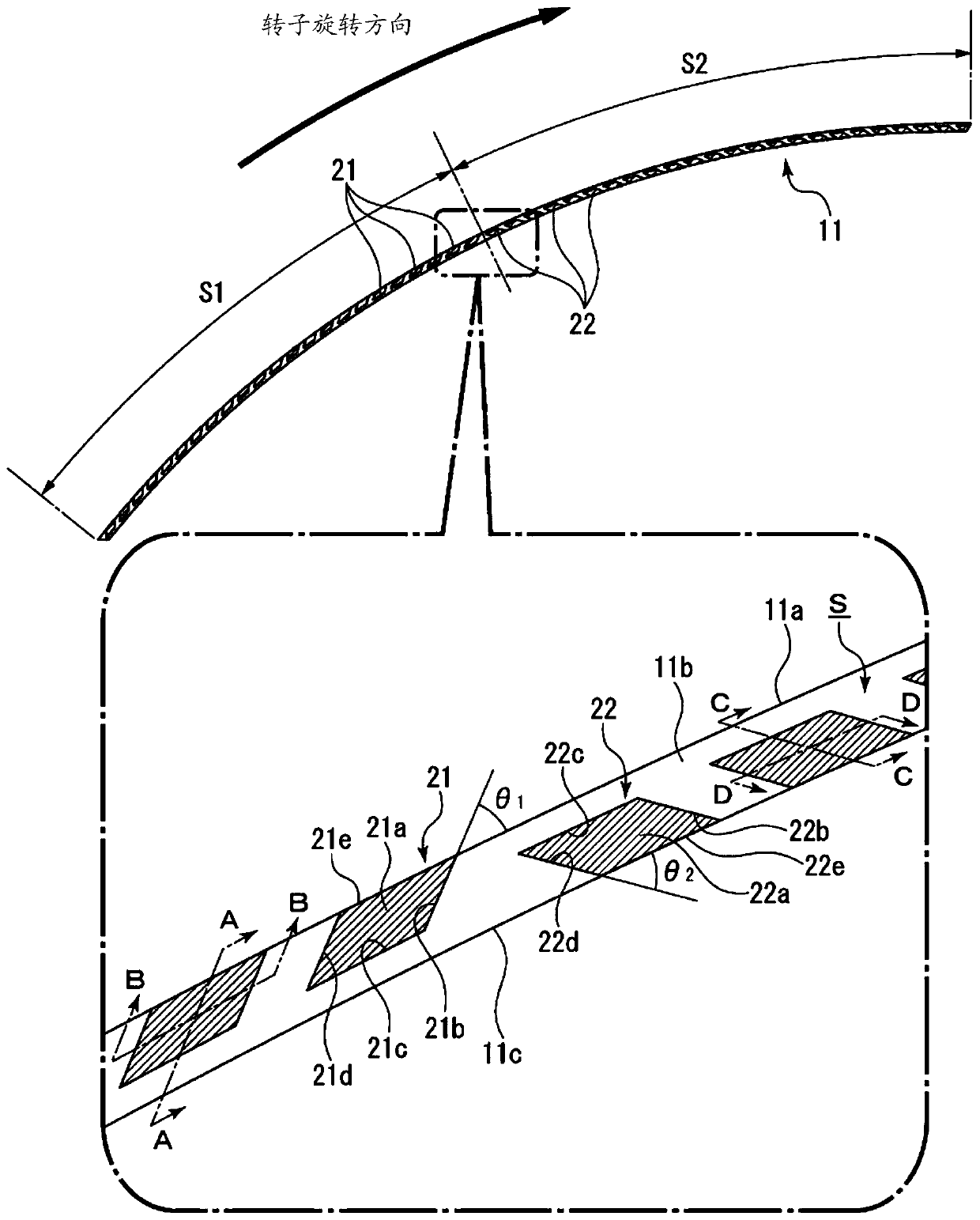

[0061] Next, combine Figure 5 , Figure 6 The sealing member of Example 2 will be described. The difference between the side seal 11 of the second embodiment and the first embodiment is that the opening direction of the first lubricating mechanism and the opening direction of the second lubricating mechanism are respectively opposite to those of the first embodiment. In addition, the same code|symbol is used for the structure which overlaps with the above-mentioned embodiment, and description is abbreviate|omitted here.

[0062] The side seal 11 of the second embodiment includes: a first lubricating mechanism 31 provided at the central portion in the longitudinal direction of the side seal 11 toward the lagging side s1 in the rotational direction; In the second lubricating mechanism 32 provided on the advancing side s2 , the first lubricating mechanism 31 has an opening 31 e that opens radially inward, and the second lubricating mechanism 32 has an opening 32 e that opens r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com