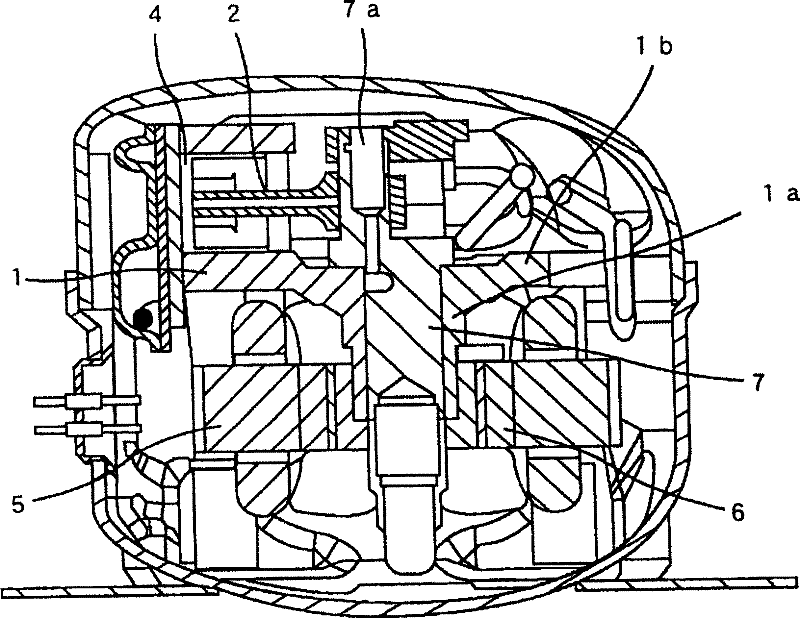

Hermetic compressor

A compressor and hermetic technology, applied in mechanical equipment, machines/engines, liquid displacement machines, etc., can solve problems such as narrow oil passages, deterioration, wear, etc., improve reliability and capacity, and reduce sliding losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] It can be seen from the above results that in order to suppress the wear caused by the corners of the flow path 2f, the effective measure is to increase the small radius portion 2d and avoid the contact between the corners of the flow path 2f and the inner spherical surface 4a of the piston 4. At this time, it is necessary to consider the surface The local concentration of pressure and the increase of average surface pressure.

[0080] In this embodiment, in order to suppress the surface pressure between the outer spherical end 2a" and the inner spherical surface 4a, the corner of the outer spherical end 2a" is obtuse, or the chamfer R is provided so that it does not become an edge. According to this configuration, it is possible to avoid contact between the flow path 2f and the inner spherical surface 4a, and to reduce abrasion due to the outer spherical surface end portion 2a" where surface pressure tends to concentrate.

[0081] In addition, as described above, since...

Embodiment 2

[0086] Next, a test was also performed on an example in which the sizes of the spherical portion 2a and the inner spherical surface 4a were the same as in Example 1, but the lubricating oil flow path 2f was different. In Example 2, the hole 2fb was used as the flow path 2f.

[0087] Also, in the case where the small-radius portion 2d is completely surrounded by the outer spherical surface of the spherical portion 2a, it is difficult to provide a flow path between the small-radius portion 2d and the surface 2a' using a groove. In this case, if the flow path 2f is provided by using the hole 2fb, the outflow and inflow path of lubricating oil can be ensured.

[0088] In this example, a hermetic compressor provided with a circular hole 2fb with a diameter of 1mm was produced, and when an actual equipment test was carried out, it was found that the ball joint structure did not disengage, and that the outer spherical end 2a" was not seen. Aggravated by excessive wear, the result of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com