Sachima syrup purification method based on polysaccharide fiber carbon degumming technology

A polysaccharide fiber and syrup technology, which is applied in the purification of sugar juice, sugar production, purification by using electricity, etc., can solve the problem that the syrup protein cannot be effectively removed, and achieve the effect of reducing the protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

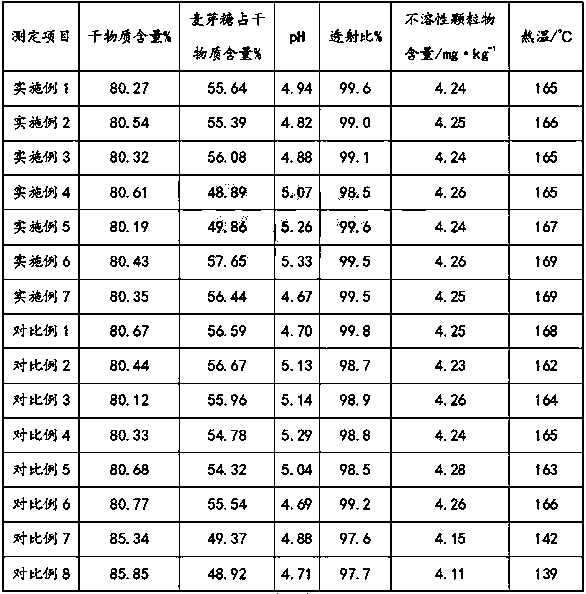

Examples

Embodiment 1

[0032] Embodiment 1: a kind of Sachima syrup purification process based on polysaccharide fiber charcoal degumming technology, comprises the following steps:

[0033] S1. Primary filtration: Add the syrup into the decolorization tank, adjust the pH of the syrup to 4.0, add filter aid perlite to the decolorization tank, the amount of filter aid added is 20kg / 75m³ syrup, adjust the temperature of the decolorization tank to 58°C, and the pressure to 0.3MPa for a filter.

[0034] S2. Secondary filtration: continue to add activated carbon to the decolorization tank, the amount of activated carbon added is 30kg / 75m³ syrup, adjust the temperature of the decolorization tank to 52°C, and the pressure to 0.3MPa for secondary filtration.

[0035] S3. Continue to pass the syrup filtered in S2 into the three sets of ion exchange devices until the resin is saturated; after the ion exchange is completed, inject water from the bottom of the ion exchange column to make the syrup come out, and ...

Embodiment 2

[0038] Embodiment 2: The difference between embodiment 2 and embodiment 1 is that the perlite addition is 30kg / 75m 3 syrup.

Embodiment 3

[0039] Embodiment 3: The difference between embodiment 3 and embodiment 1 is that the perlite addition is 40kg / 75m 3 syrup.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com