Metering and filling device used in camellia seed oil production process

A production process and technology of camellia seed oil, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of low filling efficiency, inconvenient manual operation, etc., to improve filling efficiency, facilitate manual operation, and apply wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

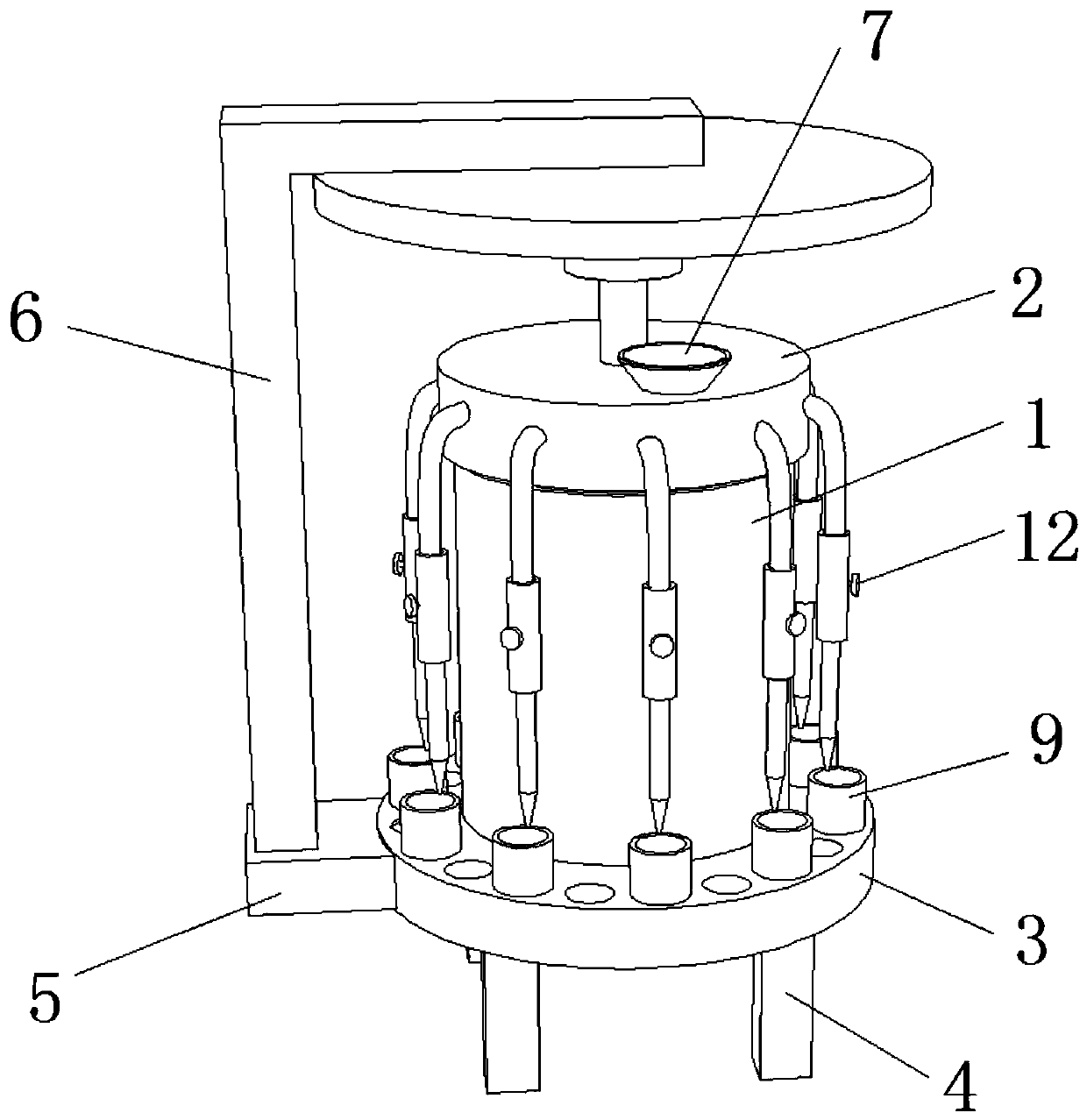

[0027] A metering and filling device for the production process of camellia oleifera seed oil, such as figure 1 As shown, it includes an oil barrel 1, the lower end of the oil barrel 1 is connected with a fixed seat 3, the lower end of the fixed seat 3 is connected with a support leg 4, and a plurality of filling bottles 9 are placed at the upper end of the fixed seat 3.

[0028] In order to solve the problem that the metering and filling device in the production process of Camellia oleifera seed oil is inconvenient for manual operation, and the filling efficiency of the filling device that is convenient for manual operation in the prior art is low; Figure 1-3 As shown, the upper end of the oil drum 1 is connected with a rotary cover 2, and the rotary cover 2 is provided with a cavity inside, the side end of the rotary cover 2 is connected with a plurality of filling guns, and the inner bottom of the oil drum 1 is connected with an oil suction pump 18, and the rotating An oil...

Embodiment 2

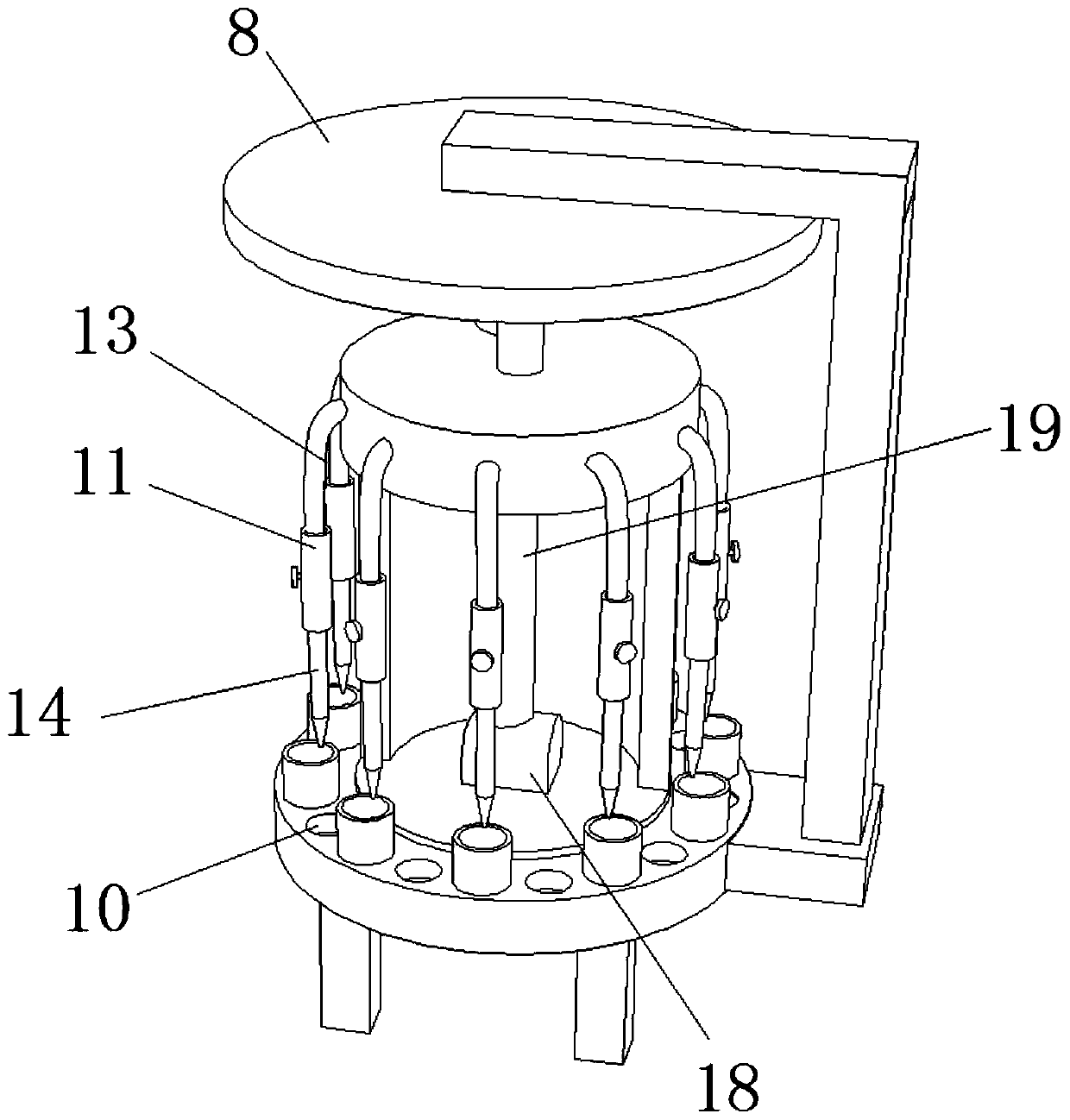

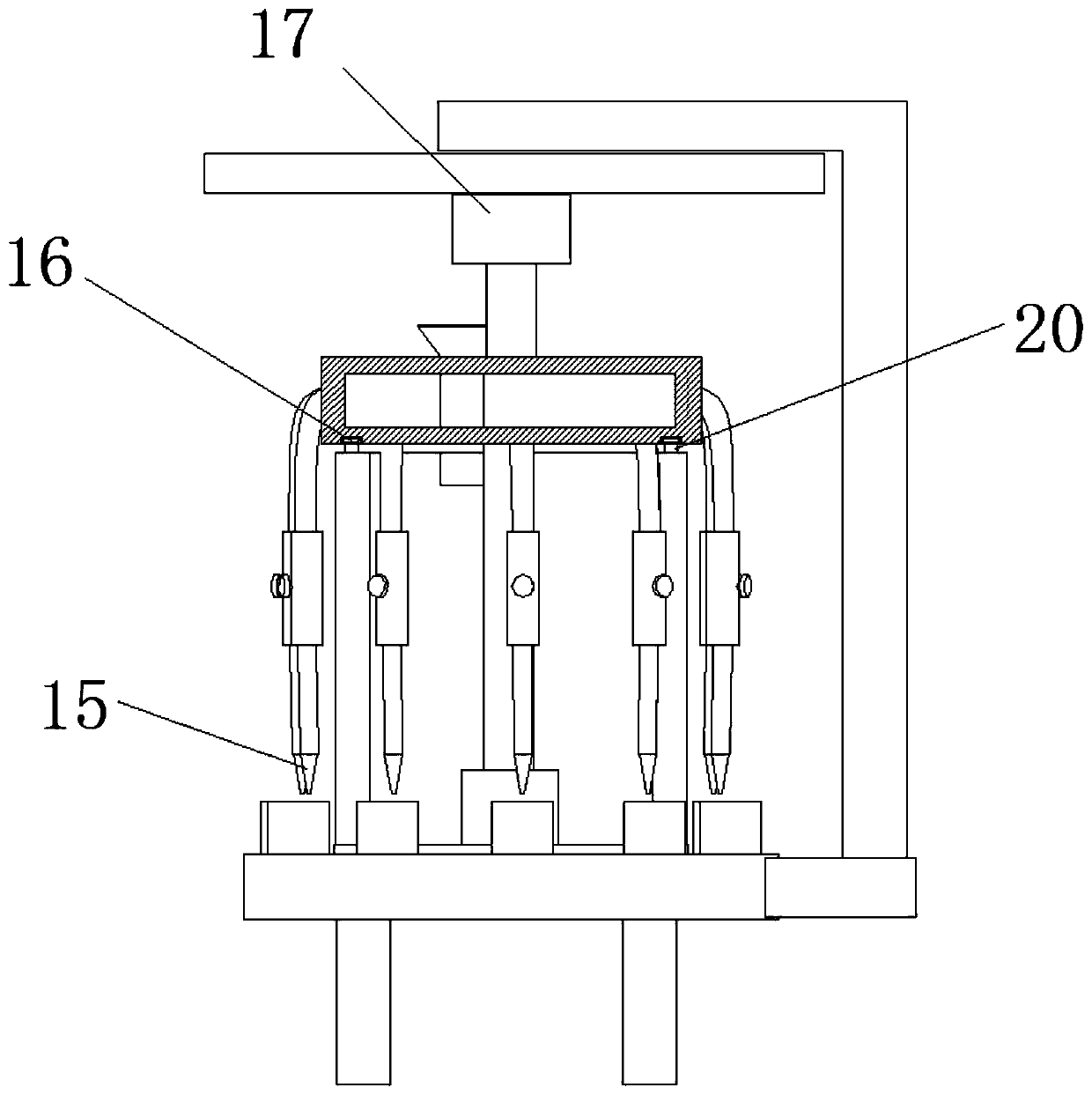

[0034] A metering and filling device for the production process of camellia oleifera seed oil, such as Figure 1-3 As shown, in order to solve the problem of filling bottles 9 of different heights; the present embodiment makes the following improvements on the basis of embodiment 1: the filling gun includes a curved pipe 13, a straight pipe 14 and a filling head 15, and the curved pipe The upper end of 13 is fixedly connected to the inner side of the rotary cover 2, an adjustment mechanism is connected between the upper end of the straight pipe 14 and the lower end of the curved pipe 13, and the filling head 15 is connected to the lower end of the straight pipe 14.

[0035] Wherein, the adjustment mechanism includes a telescopic hose and a sleeve 11, the telescopic hose is connected between the bent pipe 13 and the straight pipe 14, the sleeve 11 is sleeved on the outside of the telescopic hose, and the sleeve 11 is connected with a locking screw 12.

[0036] Wherein, the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com