Automatic weighing and material preparing system and control method thereof

An automatic weighing and batching system technology, which is applied in the direction of electric controllers, weighing, and controllers with specific characteristics, can solve the problems of consuming a lot of manpower and material resources, and prone to errors, so as to reduce investment and improve configuration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

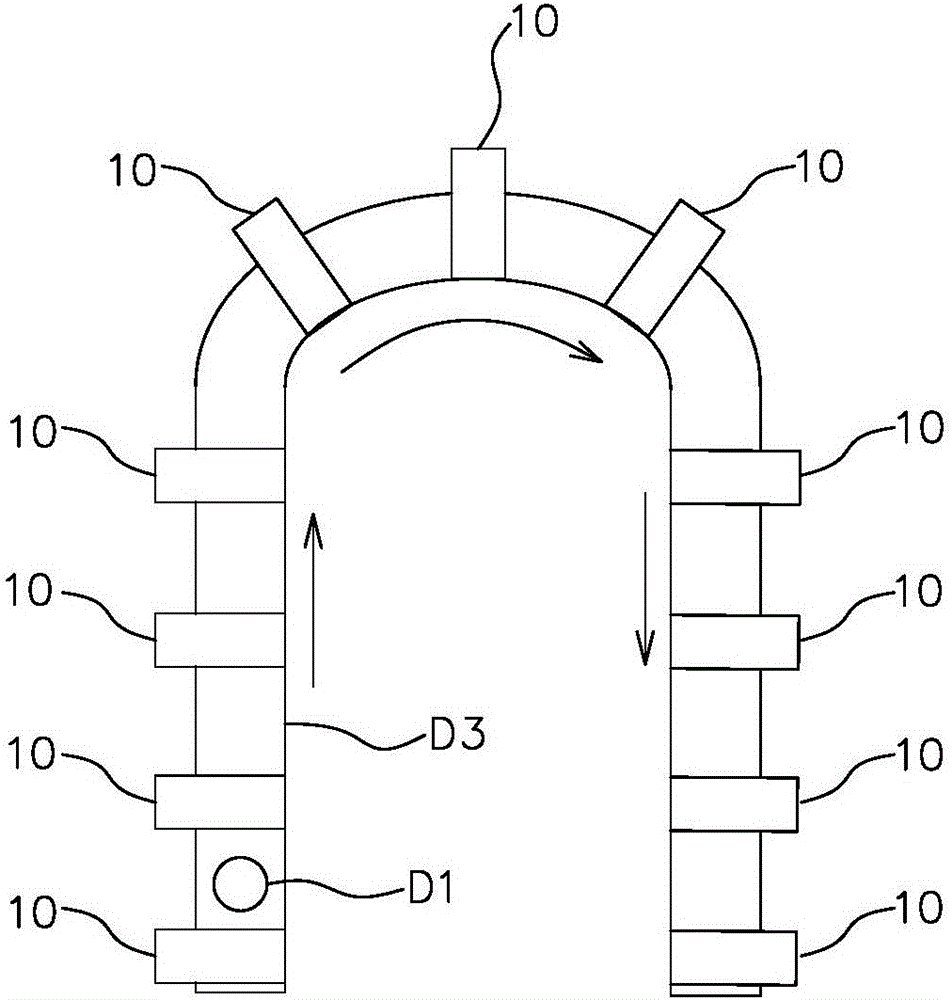

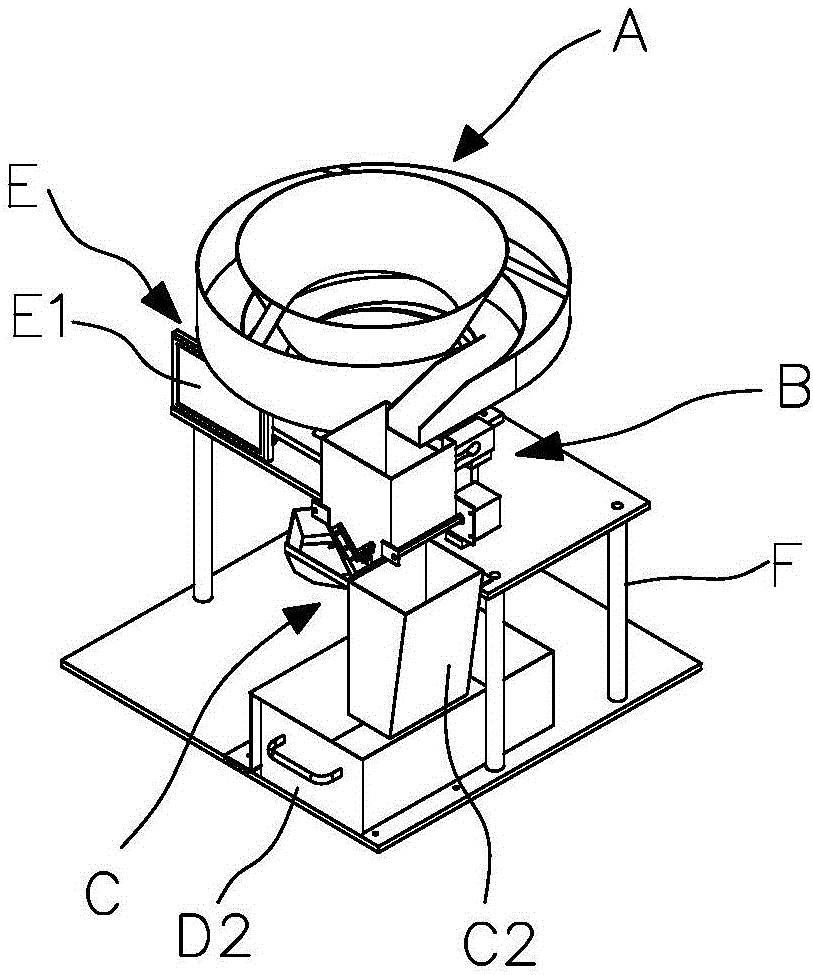

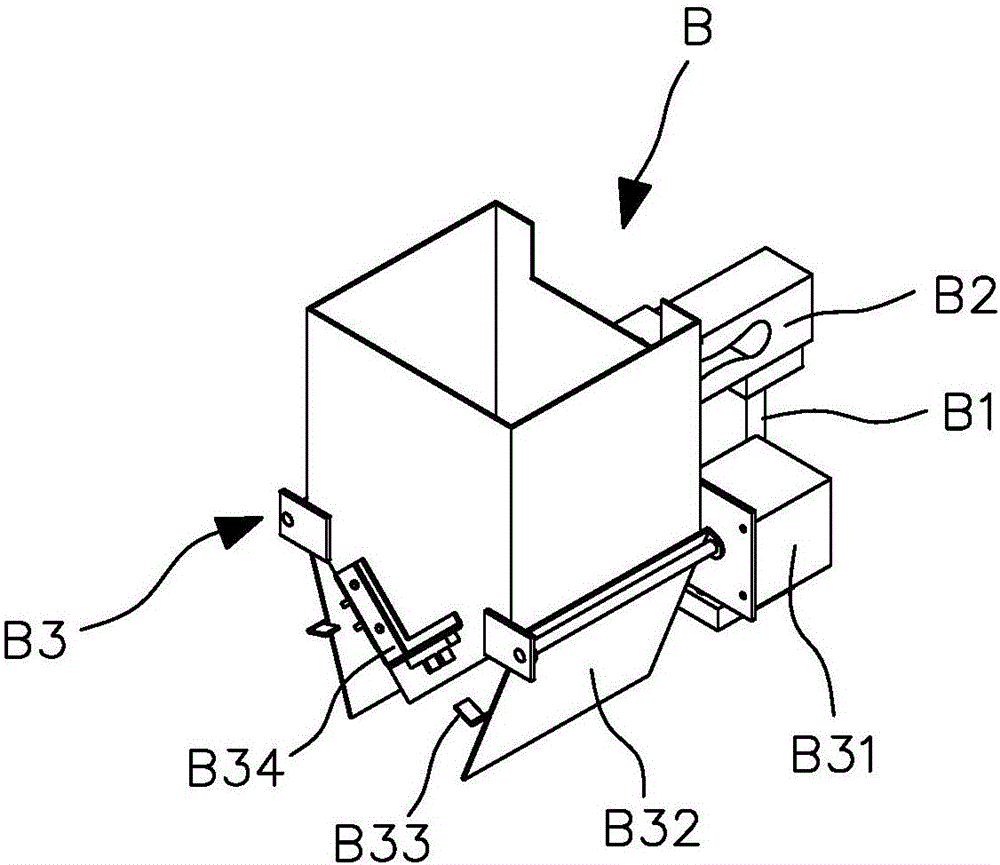

[0053] Such as figure 1 , 2 As shown, the automatic weighing and batching system includes an automatic weighing and quantitative discharging device 10 and a material collection device D, and the material collection device D includes a material receiving container D1 and a transmission device D3 for transferring the material receiving container D1 , the automatic weighing quantitative discharging device 10 has a plurality and is respectively used for weighing different material components, and the described material receiving container D1 moves on the conveying device D3 and collects the described automatic weighing quantitative discharging device one by one The material components weighed in 10; the automatic weighing quantitative discharging device 10 includes a feeding part A and a weighing part B, and the feeding part A is set as an electromagnetic vibrating feeder, and the weighing part B includes The load cell B2 fixedly connected to the support bar B1 and the two-way ho...

Embodiment 2

[0065] The control method of the automatic weighing and batching system includes the control process of the automatic weighing and quantitative discharging device, and the principle of the control process is as follows: Figure 9 As shown, it includes parameter setting module, working condition identification module, feeding speed fuzzy PID control module and parameter acquisition module;

[0066] The parameter setting module is used for the setting of the material properties, the setting of the feeding weight, the setting of the feeding speed and the selection of remote control or local control; the working condition identification module is used for collecting the baffle position signal , The real-time weight signal of the material in the two-way hopper, and the arrival signal of the receiving container on the transmission device;

[0067] If the position signal of the baffle plate, the real-time weight signal of the material in the two-way hopper, and the arrival signal of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com