Production method and production device for chemical product by continuous fermentation

A technology for manufacturing devices and manufacturing methods, which is applied in the field of chemical manufacturing and manufacturing devices based on continuous fermentation, which can solve the problems of reduced filtration capacity, inability to send culture liquid to membrane modules, and blockage, and achieve the effect of suppressing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

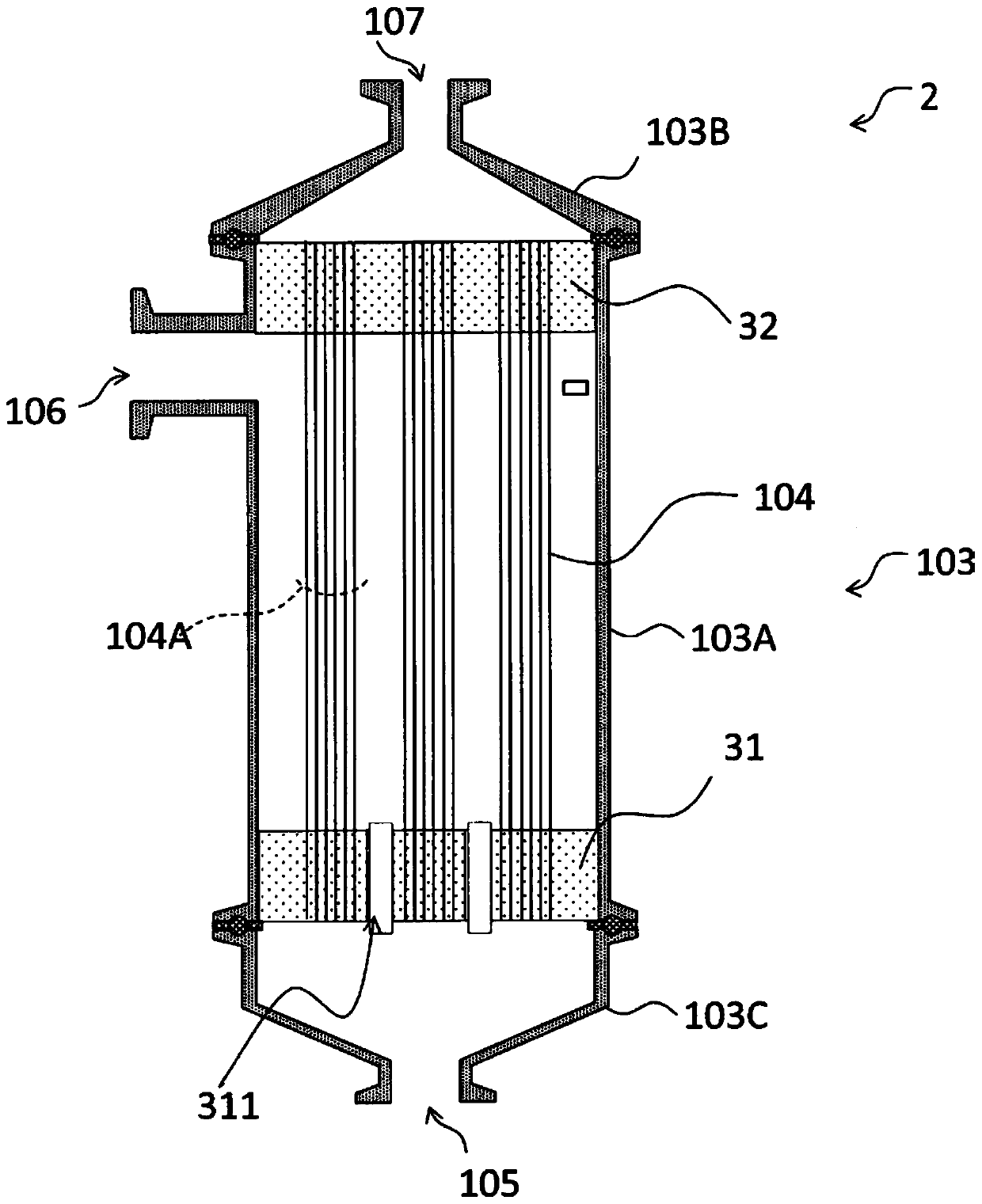

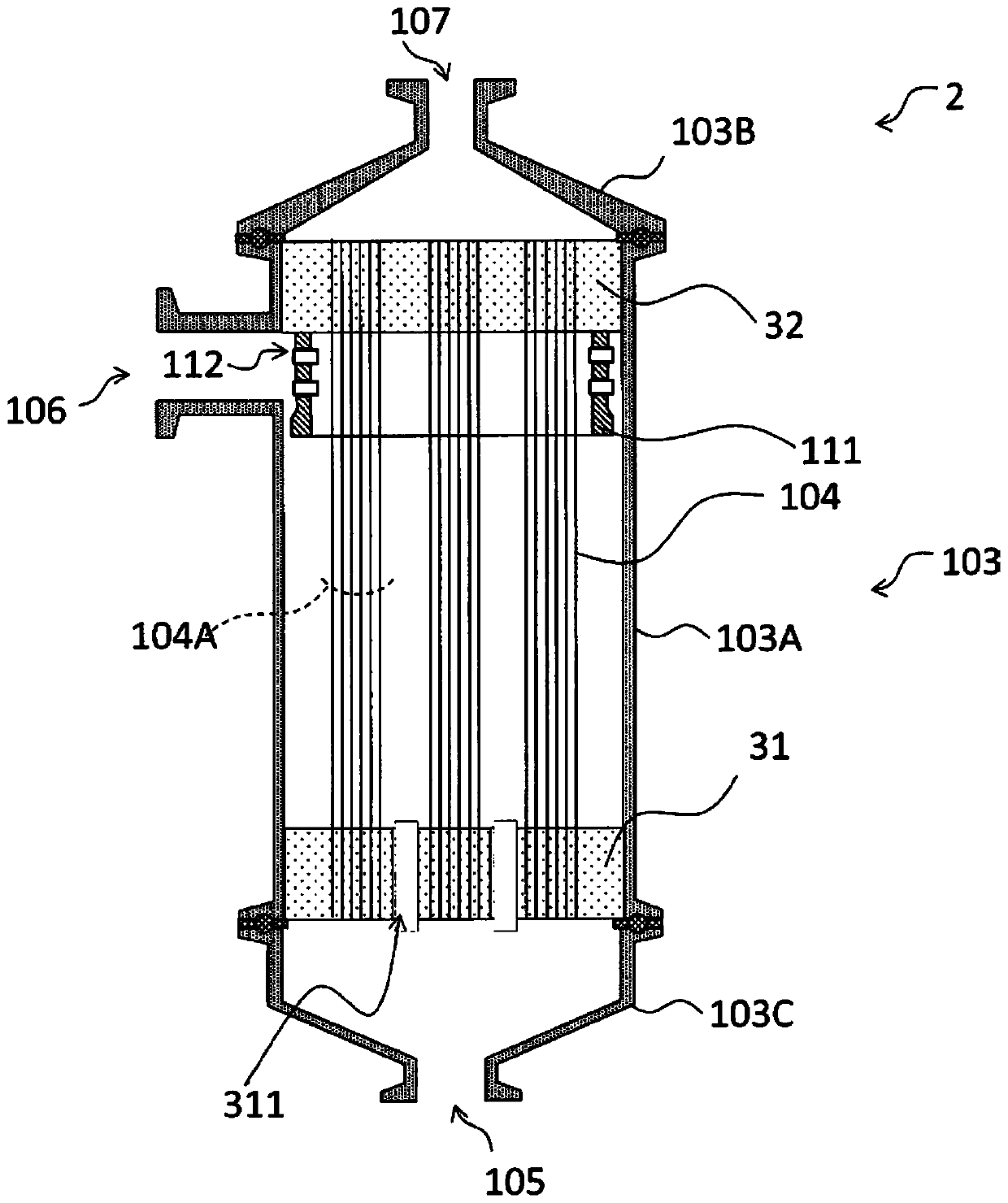

[0196] Hereinafter, an Example is shown and this invention is demonstrated more concretely. However, the present invention is not limited by these Examples. The general configuration of the continuous fermentation apparatus used in the following examples, except for the configuration related to the addition of the solid content removal mechanism and the solid content discharged from the removal mechanism, is as follows: figure 1 shown. In addition, in the following examples, lactic acid or methane was produced as a chemical by continuous fermentation.

[0197] [Measurement method of A.D-lactic acid concentration]

[0198] The concentration of D-lactic acid contained in the culture solution was measured by the following method. Confirmation was carried out by taking 100 µL of the culture solution containing D-lactic acid and measuring the amount of lactic acid by the HPLC method under the conditions shown below.

[0199] Column: Shim-Pack SPR-H (manufactured by Shimadzu Cor...

reference example 1

[0258] Using a membrane separation module with an opening of 1 mm in the removal mechanism and a major diameter of the opening of 10 mm, lactic acid fermentation was carried out under the condition that the discharge from the removal mechanism was not refluxed and not added to the fermenter. Although stable filtration was achieved at 250 hours and under the condition of a differential pressure between the membranes of 30 kPa or less, the average lactic acid accumulation concentration was 3.7 g / L from 100 h to 150 h after the start of filtration.

reference example 2

[0260] Lactic acid fermentation was performed using a membrane separation module having an opening of 0.1 mm in the removal mechanism and a major diameter of the opening of 5 mm. The results are shown in Table 1. Filtration was stable for 250 hours and the differential pressure between the membranes was 30kPa or less, and the average lactic acid accumulation concentration was 4.2g / L from 100h to 150h after the start of filtration. In addition, compared with Reference Example 1, the lactic acid accumulation concentration can be maintained higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com