Multilayer interdigitated electrochemical capacitor and its preparation method

An electrochemical and capacitor technology, applied in the field of laminated interdigitated electrochemical capacitors and its preparation, can solve the problems of reducing the overall performance-capacitance, energy density and power density, increasing structural complexity, etc., to shorten the transportation path, increased volume ratio and mass ratio, high-performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

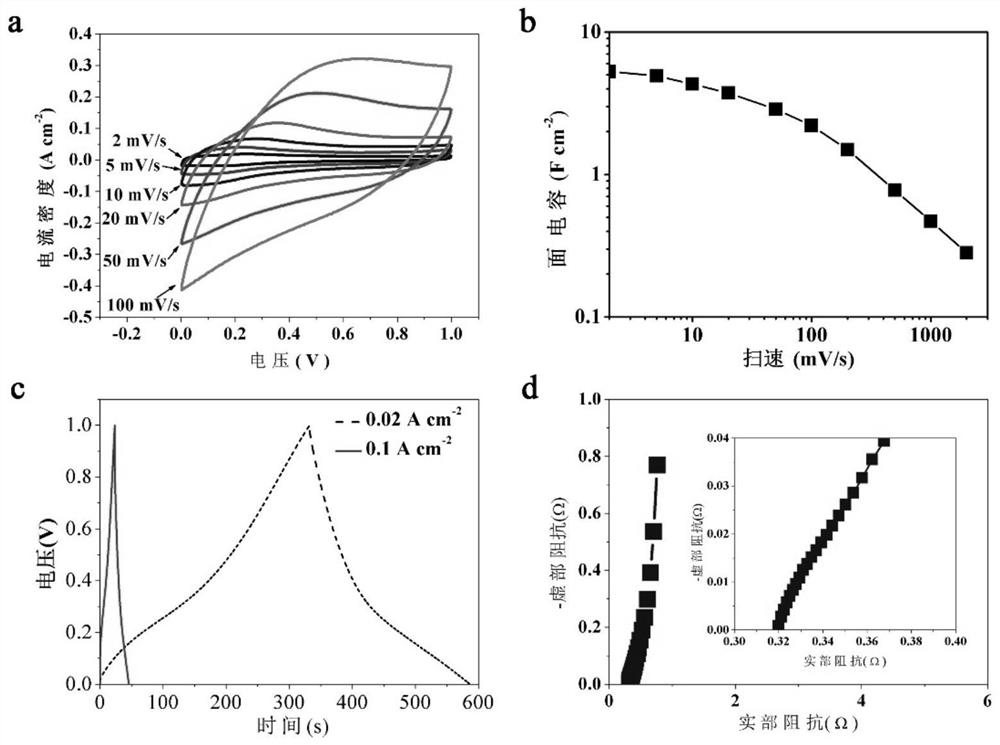

Image

Examples

Embodiment 1

[0047] The concrete steps of preparation are:

[0048] In step 1, an electrolyte is coated on the upper surface of the active self-supporting electrode; wherein, the active self-supporting electrode is an MXene titanium carbide film, and the electrolyte is sulfuric acid in an aqueous electrolyte. Then paste the diaphragm on the electrolyte to keep the two soaked, and then coat the electrolyte on it; wherein, the diaphragm is a Japanese-made NKK-MPF30AC-100 diaphragm in the water-based electrolyte diaphragm, and the upper surface is infiltrated and covered with electrolyte in sequence, Active self-supporting electrodes with separator and electrolyte.

[0049] In step 2, attach another active self-supporting electrode to the electrolyte-covered side of the previous active self-supporting electrode to keep the two wetted, and then coat the surface with electrolyte. After the diaphragm is pasted on the electrolyte to keep the two wetted, the electrolyte is coated on it to obtain ...

Embodiment 2

[0052] The concrete steps of preparation are:

[0053] In step 1, an electrolyte is coated on the upper surface of the active self-supporting electrode; wherein, the active self-supporting electrode is an MXene titanium carbide film, and the electrolyte is sulfuric acid in an aqueous electrolyte. Then paste the diaphragm on the electrolyte to keep the two soaked, and then coat the electrolyte on it; wherein, the diaphragm is a Japanese-made NKK-MPF30AC-100 diaphragm in the water-based electrolyte diaphragm, and the upper surface is infiltrated and covered with electrolyte in sequence, Active self-supporting electrodes with separator and electrolyte.

[0054] In step 2, attach another active self-supporting electrode to the electrolyte-covered side of the previous active self-supporting electrode to keep the two wetted, and then coat the surface with electrolyte. After the diaphragm is pasted on the electrolyte to keep the two wetted, the electrolyte is coated on it to obtain ...

Embodiment 3

[0057] The concrete steps of preparation are:

[0058] In step 1, an electrolyte is coated on the upper surface of the active self-supporting electrode; wherein, the active self-supporting electrode is an MXene titanium carbide film, and the electrolyte is sulfuric acid in an aqueous electrolyte. Then paste the diaphragm on the electrolyte to keep the two soaked, and then coat the electrolyte on it; wherein, the diaphragm is a Japanese-made NKK-MPF30AC-100 diaphragm in the water-based electrolyte diaphragm, and the upper surface is infiltrated and covered with electrolyte in sequence, Active self-supporting electrodes with separator and electrolyte.

[0059] In step 2, attach another active self-supporting electrode to the electrolyte-covered side of the previous active self-supporting electrode to keep the two wetted, and then coat the surface with electrolyte. After the diaphragm is pasted on the electrolyte to keep the two wetted, the electrolyte is coated on it to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com