Solid-state stacked interdigitated electrochemical capacitor and its preparation method

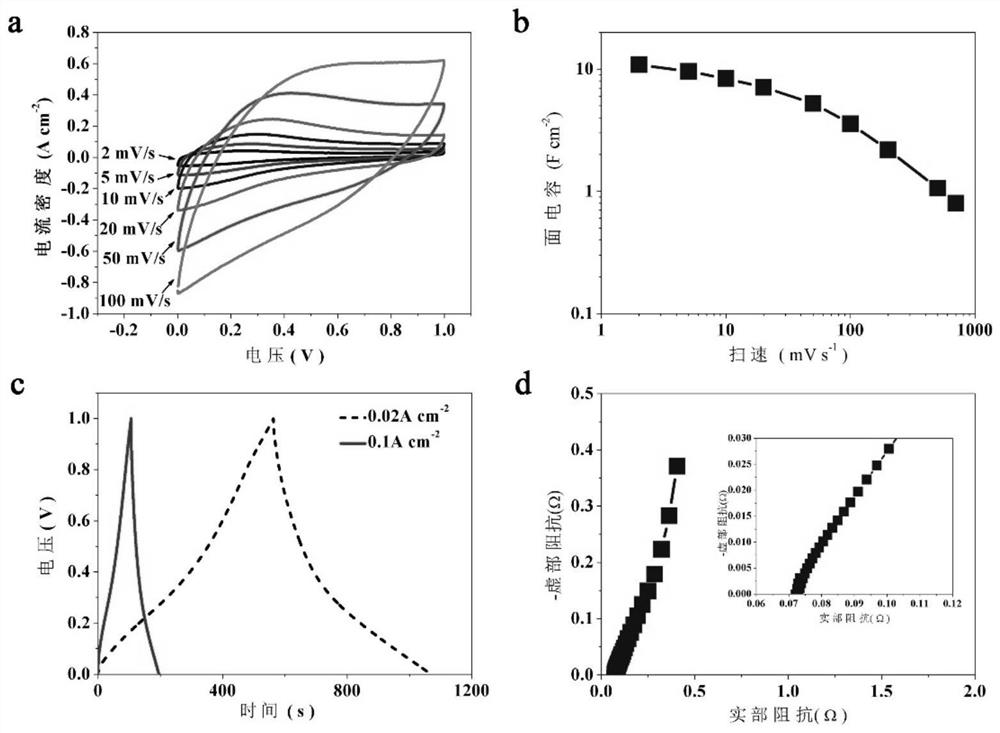

A laminated fork, electrochemical technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problem of reducing overall performance - capacitance, energy density and power density, increasing structural complexity problems such as stability, etc., to achieve the effect of shortening the transport path, increasing the volume ratio and mass ratio, and high power output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The concrete steps of preparation are:

[0045] In step 1, a 20 μm thick gel electrolyte is coated on the upper surface of the active self-supporting electrode; wherein, the active self-supporting electrode is an MXene titanium carbide film, and the gel electrolyte is a polyvinyl alcohol-sulfuric acid gel electrolyte. Then place it under a vacuum degree of -0.08Mpa for 3 minutes to obtain an active self-supporting electrode whose upper surface is soaked with a gel electrolyte.

[0046]In step 2, another active self-supporting electrode is pasted on the surface of the previous active self-supporting electrode soaked with the gel electrolyte, and then a 20 μm-thick gel electrolyte is coated on its surface. Then place it under a vacuum degree of -0.08Mpa for 3 minutes to obtain an active self-supporting electrode with the upper surface of the multilayer impregnated with gel electrolyte.

[0047] Step 3, first paste another active self-supporting electrode on the side of t...

Embodiment 2

[0049] The concrete steps of preparation are:

[0050] In step 1, a 25 μm thick gel electrolyte is coated on the upper surface of the active self-supporting electrode; wherein, the active self-supporting electrode is an MXene titanium carbide film, and the gel electrolyte is a polyvinyl alcohol-sulfuric acid gel electrolyte. Then place it under a vacuum degree of -0.09Mpa for 2.5 minutes to obtain an active self-supporting electrode with gel electrolyte soaked on the upper surface.

[0051] In step 2, another active self-supporting electrode is pasted on the surface of the previous active self-supporting electrode soaked with the gel electrolyte, and then a 25 μm thick gel electrolyte is coated on the surface. Then place it under a vacuum degree of -0.09Mpa for 2.5 minutes to obtain an active self-supporting electrode with the upper surface of the multilayer impregnated with gel electrolyte.

[0052] In step 3, after repeating the process of step 2 for 8 times, another active...

Embodiment 3

[0054] The concrete steps of preparation are:

[0055] In step 1, a 30 μm thick gel electrolyte is coated on the upper surface of the active self-supporting electrode; wherein, the active self-supporting electrode is an MXene titanium carbide film, and the gel electrolyte is a polyvinyl alcohol-sulfuric acid gel electrolyte. Then place it under a vacuum degree of -0.1Mpa for 2 minutes to obtain an active self-supporting electrode with gel electrolyte soaked on the upper surface.

[0056] In step 2, another active self-supporting electrode is pasted on the surface of the previous active self-supporting electrode soaked with the gel electrolyte, and then a 30 μm thick gel electrolyte is coated on the surface. Then place it under a vacuum degree of -0.1Mpa for 2 minutes to obtain an active self-supporting electrode with the upper surface of the multilayer impregnated with gel electrolyte.

[0057] In step 3, after repeating the process of step 2 for 15 times, another active self...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com