Water and oil temperature sensor for automobile and manufacturing method thereof

The technology of an oil temperature sensor and its production method, which is applied in the field of vehicle sensors, can solve the problems of easy breakage of the engine, crushing of the ceramic sensor head, inconsistent thermal expansion and cold contraction, etc., and achieve the effect of saving the production cost of the closure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

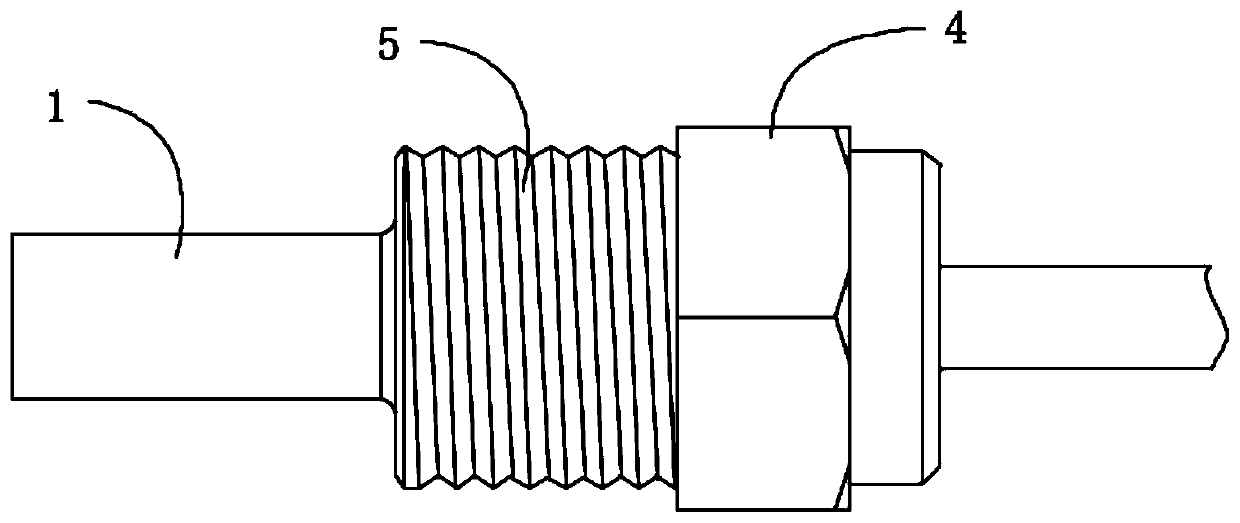

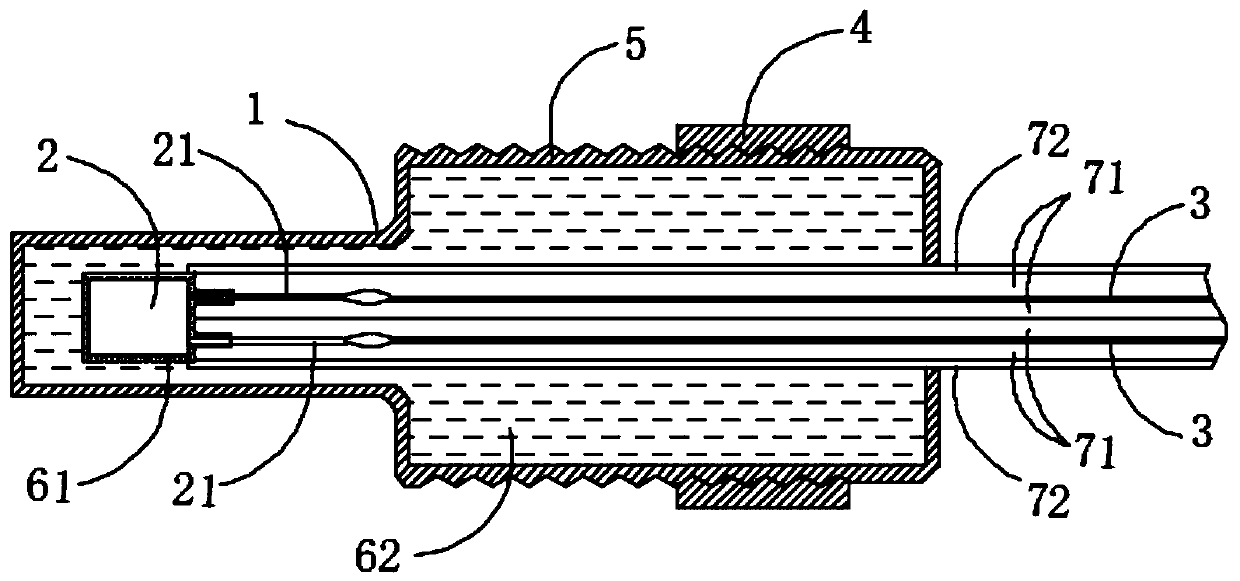

[0023] see Figure 1-2 Shown, the specific embodiment that the present invention provides is as follows:

[0024] A kind of automobile water and oil temperature sensor of the present embodiment, comprises induction head shell 1, ceramic induction head 2, two wires 3, fixing nut 4 and sheath assembly; Two pins of described ceramic induction head 2 terminals 21 and the two wires 3 are welded and fixed respectively, such as connecting the pins and the wires through resistance welding; the ceramic induction head 2 and the two wires 3 are installed in the induction head housing 1 and there is a gap between the induction head housing, so The fixed nut is fastened and installed with the tail of the sensor head housing, and the outer wall of the tail of the sensor head housing 1 is provided with a mounting thread 5, and the sheath assembly is used to isolate the two wires to insulate the two wires.

[0025] In a preferred embodiment, the ceramic induction head and the induction head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com