Smoke air preheater for increasing garbage incineration primary combustion supporting air temperature

An air preheater and combustion-supporting air technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of refractory castable peeling, heat exchange tube burst accidents, and few applications, so as to achieve convenient maintenance and reduce The effect of reducing energy consumption and reducing resistance loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

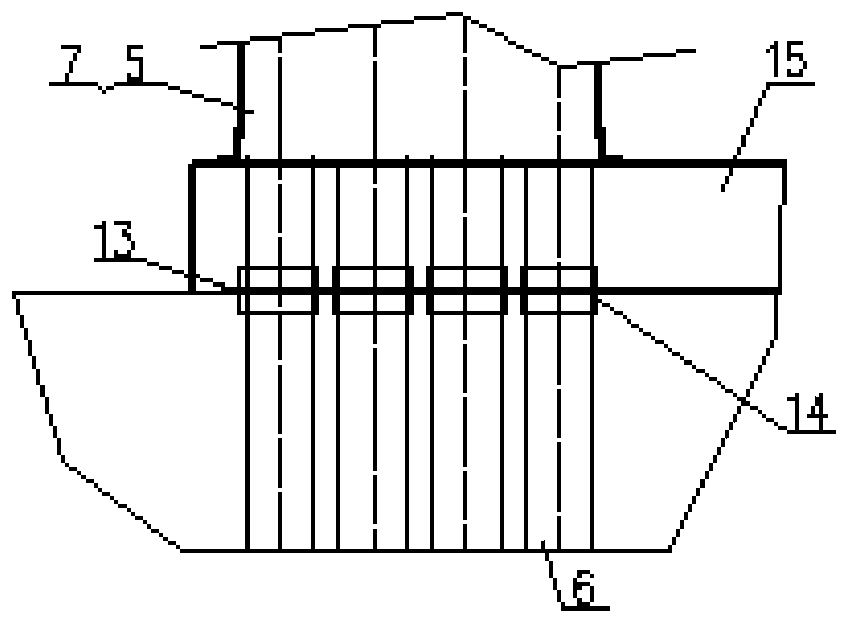

[0026] The specific implementation of the flue gas air preheater used for increasing the temperature of primary combustion-supporting air in waste incineration according to the present invention will be further described in detail with reference to the accompanying drawings.

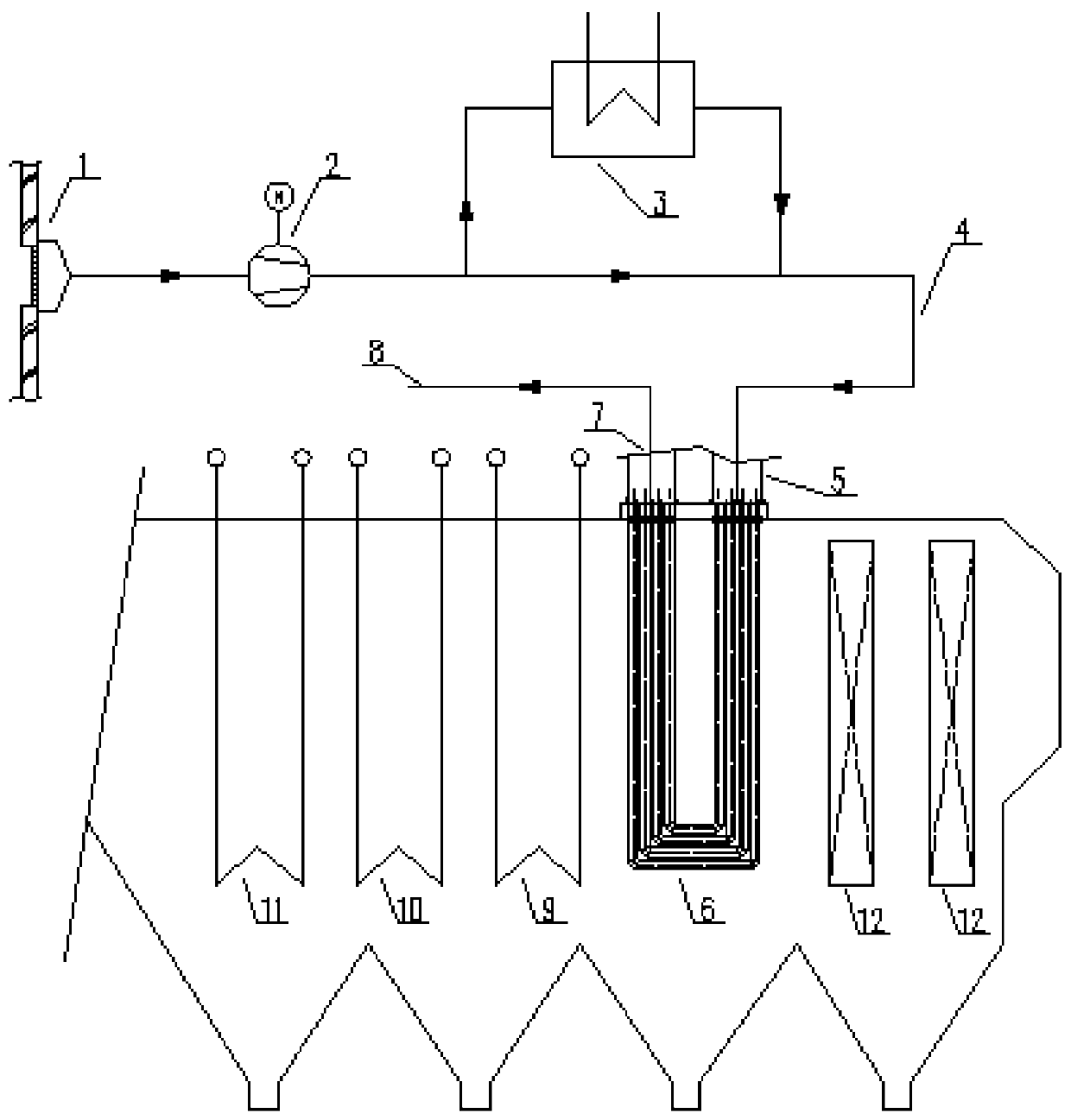

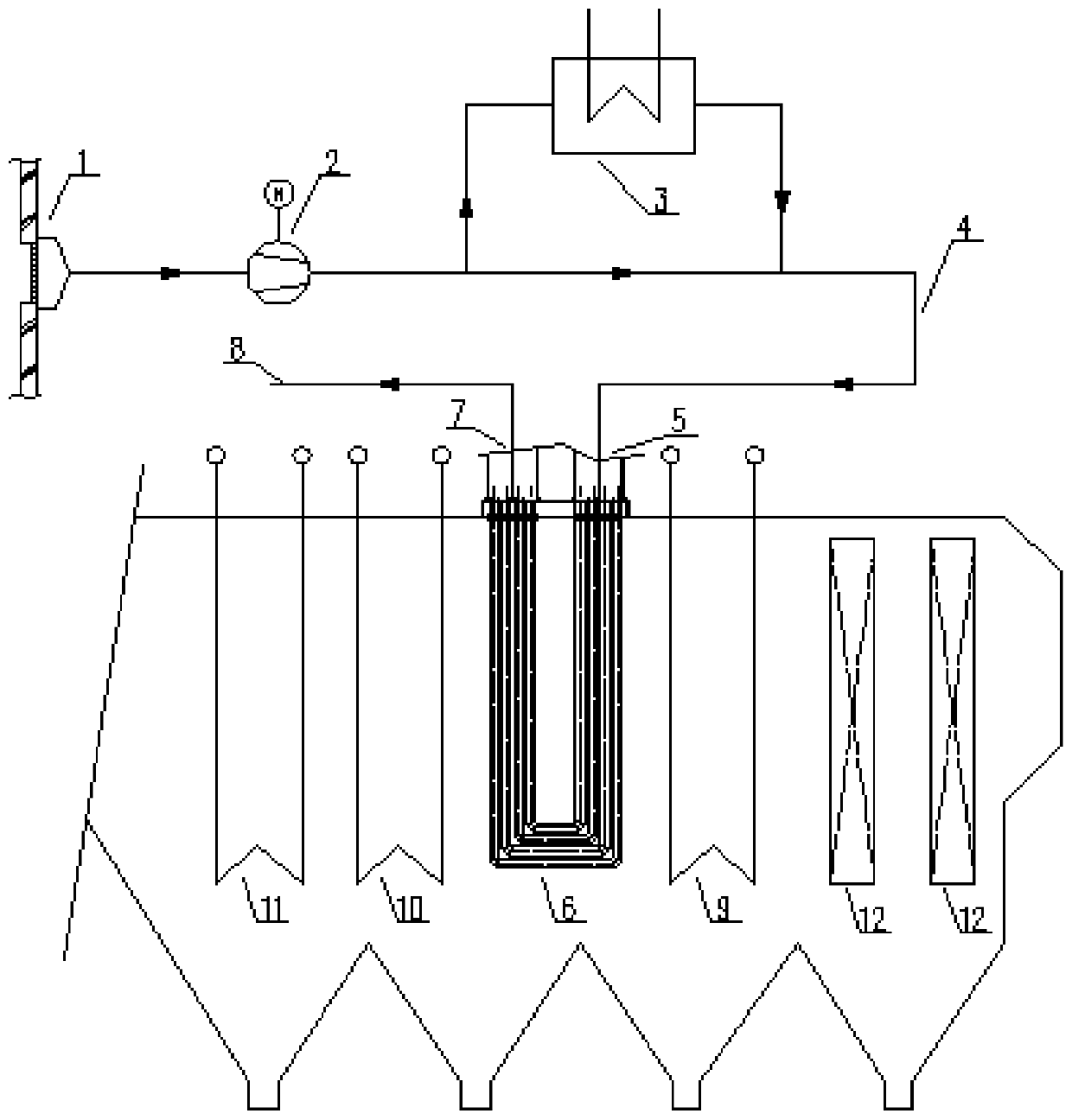

[0027] like figure 1 , figure 2 As shown, taking the horizontal boiler as an example, the process flow is: the primary air is sucked by the primary fan 2 from the air suction port 1 above the garbage bin, heated by the steam air preheater 3, and fed into the flue gas air through the primary air duct inlet 4 The inlet header 5 of the preheater is heated to a certain temperature by the high temperature flue gas through the heat exchange tube 6, and then sent out from the outlet header 7 of the flue gas air preheater, and finally sent to the incinerator through the outlet 8 of the primary air duct. in the wind room.

[0028] In principle, different calorific values of waste require different temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com