Intelligent pile hole inner muck suction machine and pile hole muck automatic suction method

A soil suction machine and muck technology, which is applied to sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of caking or sticking on the inner wall of the collecting device, difficult to control the falling speed, and less soil mass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

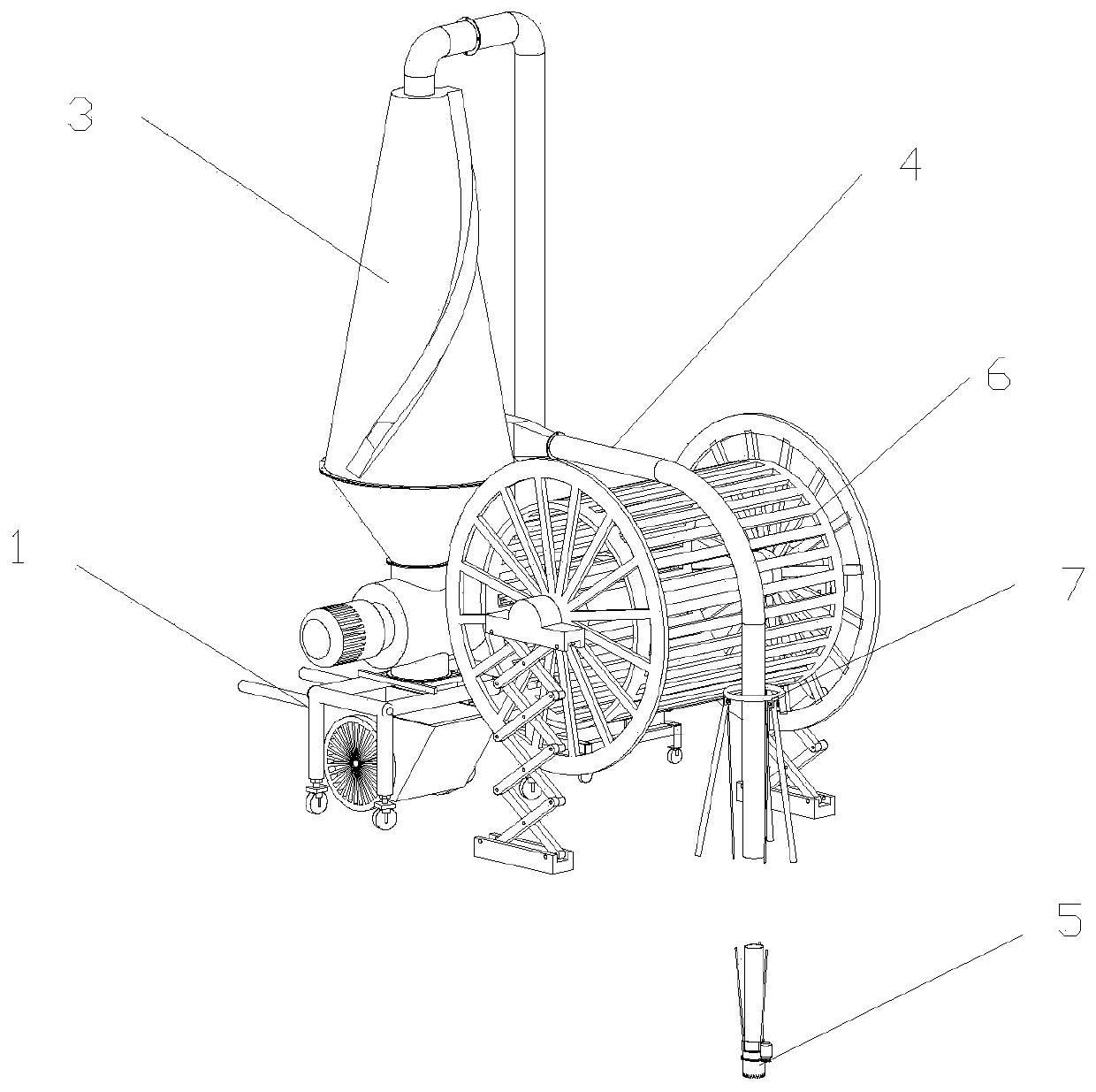

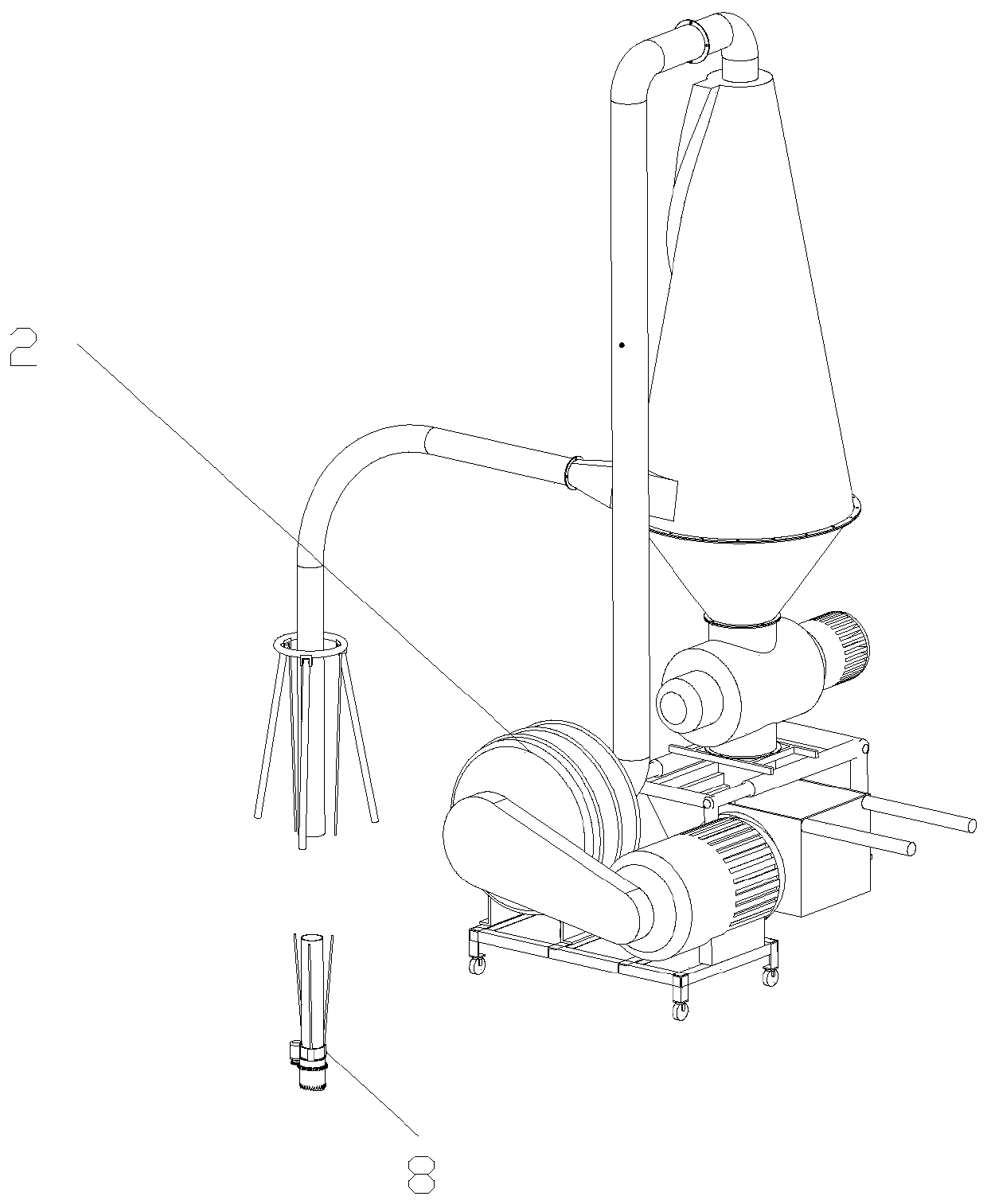

[0069] see figure 1 and 2 , the pile hole muck soil suction machine of this embodiment includes a chassis 1, a blower fan 2, a suction separation device 3, a suction pipe 4, a suction unit 5, a pipeline retractable mechanism 6, a suction moving mechanism 7, a controller 9, a general Control platform 10 and imaging mechanism 8; Wherein,

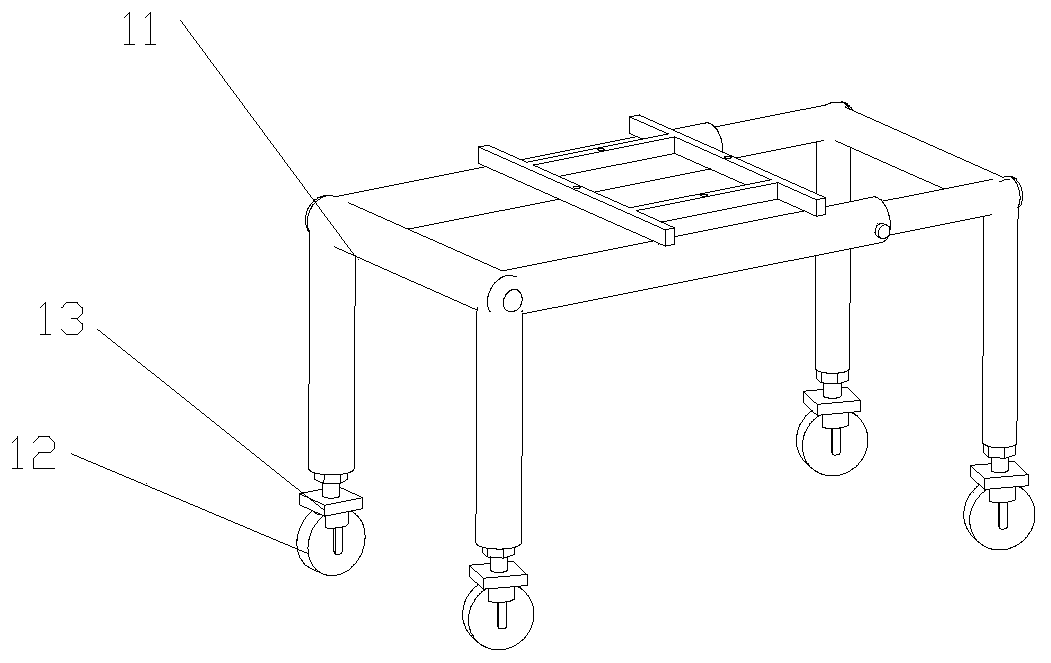

[0070] The chassis 1 provides an installation platform for the suction separation device 3 and the fan 2; as image 3 As shown, the underframe 1 includes a frame body 11, running wheels 12 and a locking mechanism 13. The four running wheels 12 are installed on the four corners of the bottom of the frame body 11 to drive the frame body 11 to slide. A locking mechanism 13 is installed at the wheel 12, and the running wheel 12 is locked and fixed by the locking mechanism 13. The frame body 11 is a telescopic frame body 11 composed of beams, longitudinal beams and supporting legs, that is, the beams, longitudinal beams and supporting legs are a...

Embodiment 2

[0096] The difference between the structure of the pile hole dreg soil suction machine of the present embodiment and embodiment 1 is:

[0097] The vortex separation cylinder 31 of the suction separation device 3 is a conical cylinder structure with a cone angle of 45° and a height of 3m; The direction of the air flow in the inner cavity of the vortex separation cylinder 31 is opposite to that of the vortex separator, and the helix angle of the muck collection tank 32 is 30°, and the pitch is 6m. The discharge valve 34 of the present embodiment is fixed on the chassis 1, and five rotating blades 344 are arranged in the inner cavity of the valve body 341. The rotating blades 344 are rectangular plates and are evenly distributed along the radial direction of the rotating shaft 342. Take the rotating shaft 342 as the central shaft 561 to rotate, the rotating shaft 342 is horizontally arranged, and is connected to the output shaft of the unloading driving motor 343 through a bearin...

Embodiment 3

[0116] The difference between the structure of the pile hole dreg soil suction machine of the present embodiment and embodiment 1 is:

[0117] In the present embodiment, the free end side wall of the suction pipe 4 is processed with a rotating through groove.

[0118] The vortex separation cylinder 31 of the suction separation device 3 is a conical cylinder structure with a cone angle of 45° and a height of 3m; Contrary to the direction of the air flow in the inner cavity of the vortex separation cylinder 31, the muck collection groove 32 protrudes outward along the wall of the vortex separation cylinder 31 and the notch is opened towards the central axis of the vortex separation cylinder 31, and runs along the wall of the vortex separation cylinder 31 from top to bottom Inclined setting enables the collected muck to slide and move from top to bottom. The inclination angle of the muck collecting tank 32 is 30°~60°, preferably 30~45°.

[0119] The suction unit 5 includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com