Garment cut-parts visible thread and invisible thread integrated ironing-free sewing production line

An integrated, light and dark line technology, applied in the direction of garment transporters, sewing equipment, sewing machine components, etc., can solve problems such as reduction, and achieve the effects of reducing labor, saving production costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

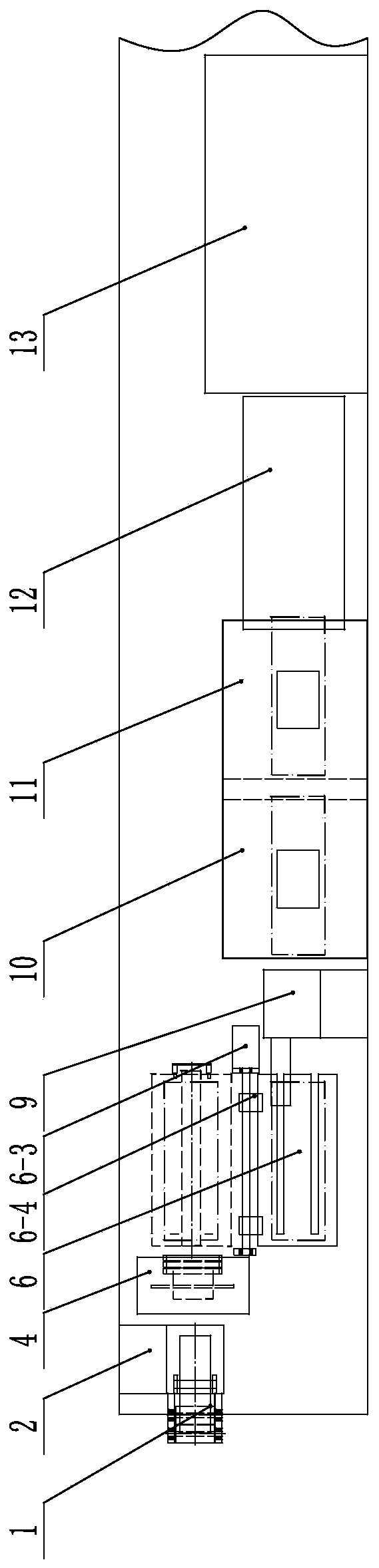

[0047] The present invention will be further described below in conjunction with accompanying drawing.

[0048] Such as Figure 1-6 As shown, a kind of clothing cutting piece bright and dark line integrated non-ironing sewing production line of the present invention comprises frame platform 15, lining strip film-feeding mechanism 1, also includes:

[0049] The concealed thread sewing machine 2 is arranged on the frame platform 15, and the concealed thread sewing machine 2 is provided with a lining strip film-feeding mechanism 1, and the lining strip film-feeding mechanism 1 cooperates with the upper cutting pieces 16 and The lower panel 17 is jointly sewed by the concealed thread sewing machine 2;

[0050] The cutting device 4 is arranged on the rear side of the concealed thread sewing machine 2, and is used to cut off the lining strips between the pieces;

[0051] The piece turning mechanism 6 is arranged on the rear side of the cutting device 4, and is used to turn over th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com