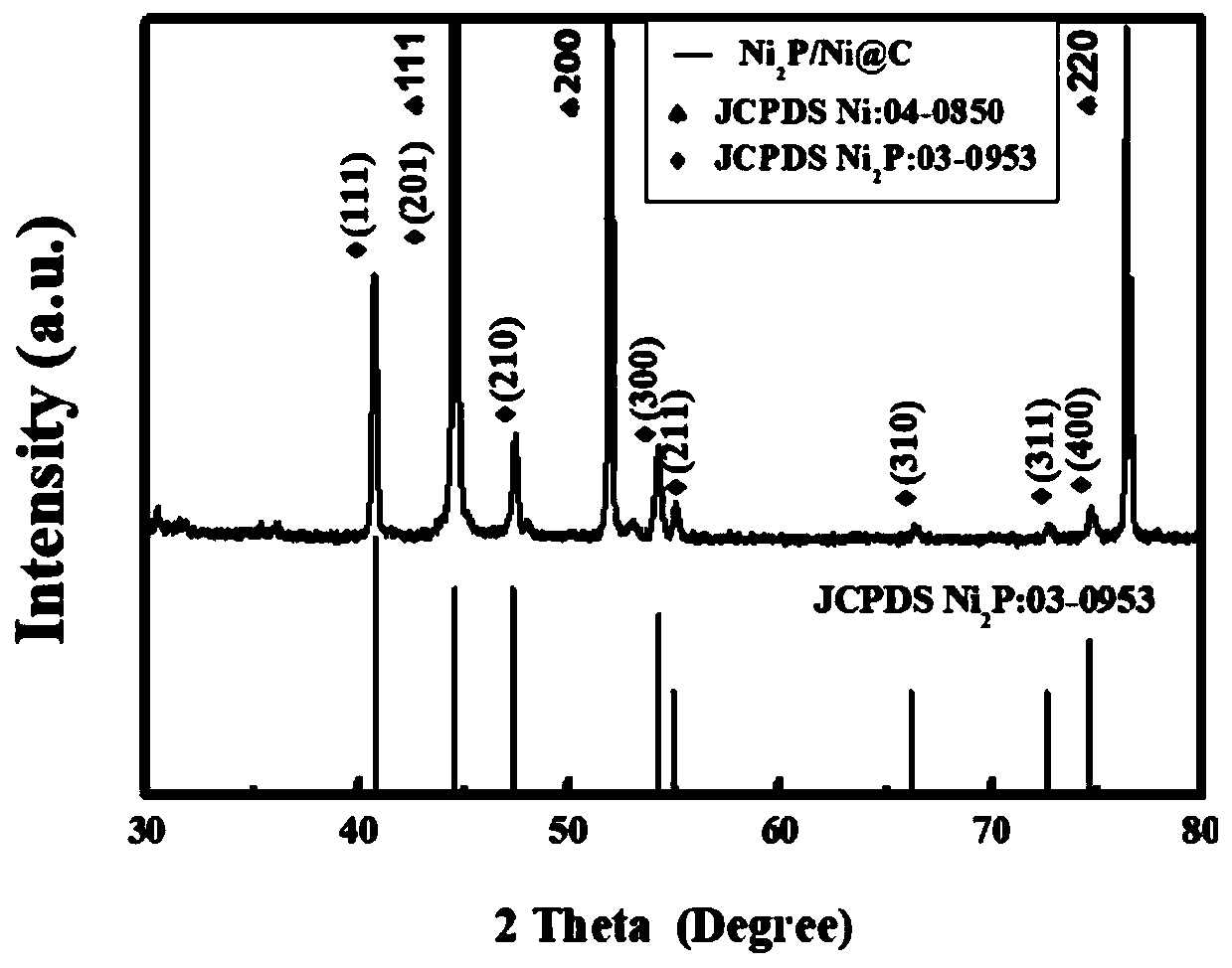

Self-supported Ni2P/Ni@C composite cathode hydrogen evolution material and preparation method thereof

A composite cathode, self-supporting technology, applied in chemical instruments and methods, electrodes, electrode shapes/types, etc., can solve problems affecting the surface activity of nickel phosphide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Take an area of 1×2cm 2 The porous Ni@C material was cleaned with deionized water and absolute ethanol, respectively. Weigh 0.21g nickel sulfate hexahydrate (NiSO 4 ·6H 2 O), 0.06g ammonium fluoride (NH 4 F) and 0.24g urea [CO(NH 2 ) 2 ] was dissolved in 20mL of deionized water, stirred to dissolve completely, then transferred to a polytetrafluoroethylene autoclave, and the porous Ni@C composite substrate was placed in the autoclave, and reacted at a constant temperature of 140°C for 5h, and the material was cooled Take it out, wash it with ethanol, and dry it in vacuum at 50° C. for 2 hours to obtain a precursor of nickel hydroxide. Finally, the porcelain boat containing the precursor was put into the tube furnace, nitrogen was used as the protective gas, and 0.2g NaH 2 PO 2 ·H 2 O is placed at the front of the nitrogen flow, kept at 400°C for 2 hours, and cooled to room temperature to obtain Ni with multidimensional pore morphology. 2 P / Ni@C composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com