Preparation method, catalyst and preparation method of molybdenum disulfide/carbon composite material

A technology of molybdenum disulfide and composite materials, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limited electron transfer electrochemical kinetic performance, poor conductivity of molybdenum disulfide, and reduced activity site and other issues, to achieve the effect of cheap raw materials, low cost, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In order to prepare the composite material of the sandwich structure, one of the ways that the applicant thinks of is to use a single layer of molybdenum disulfide nanosheets and graphene nanosheets to composite. However, the exfoliation and recombination of molybdenum disulfide and graphite need to consume a lot of time. , thus hampering the synthesis of sandwich-structured MoS2-graphene composites. For this reason, the inventor has redesigned its preparation method, and the preparation method of the molybdenum disulfide-graphitized carbon composite material according to another exemplary embodiment of the present invention includes carrying out water treatment on a sulfur-containing reducing agent, molybdate and ascorbic acid. Thermal synthesis reaction; roast the product of hydrothermal synthesis reaction to obtain molybdenum disulfide-graphitized carbon composite material. In an exemplary embodiment, the preparation method of the molybdenum disulfide-graphitized car...

example 1

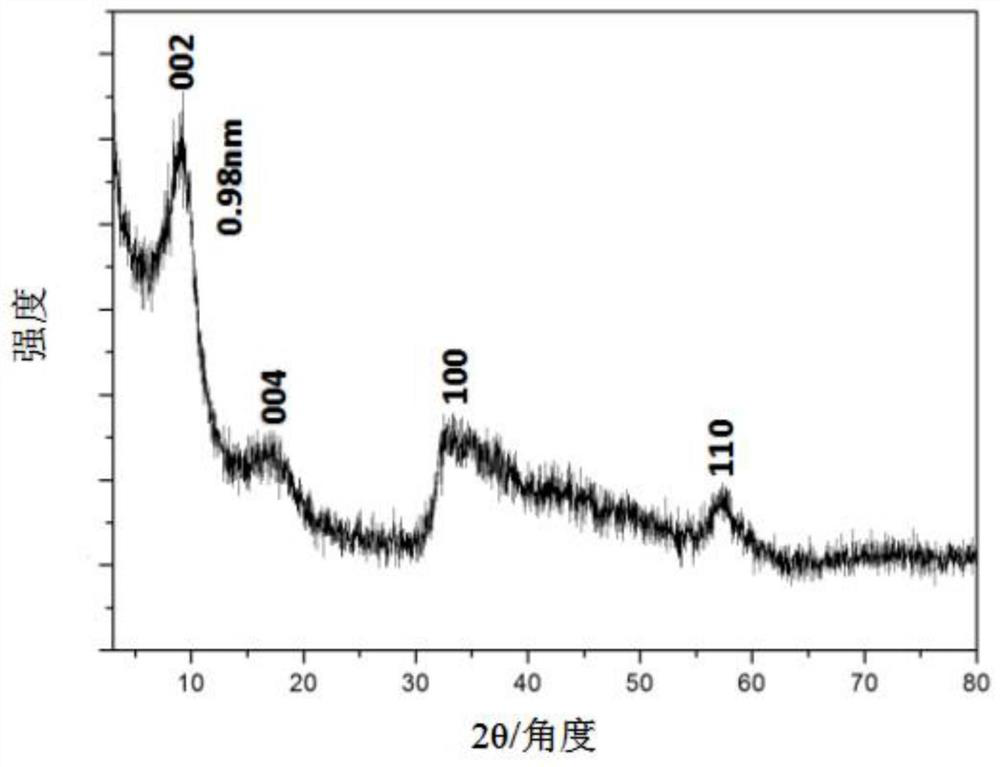

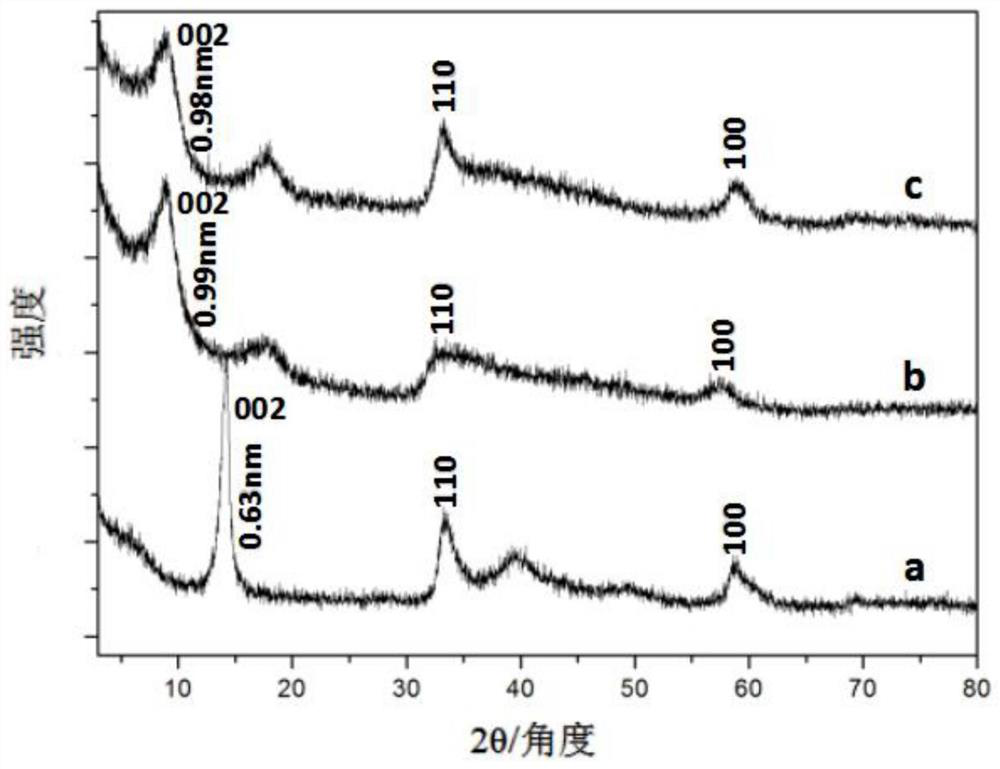

[0038]Weigh 3mmol sodium molybdate and add it to two 50ml reaction kettles with 30ml deionized water, then add 18mmol thiourea and 6mmol ascorbic acid respectively, stir at room temperature for 30min, then put the reaction kettle into an oven at 230°C for heating After 24 hours, filter and wash to obtain molybdenum disulfide nanomaterials intercalated with organic matter, and then bake at 800°C for 2 hours to obtain molybdenum disulfide-carbon composites with a "sandwich" structure, such as figure 1 The X-ray diffraction pattern shows the generation of organic intercalation molybdenum disulfide and molybdenum disulfide-graphitized carbon composites, and the (002) plane is 0.98nm due to the interlayer spacing of graphitized carbon.

example 2

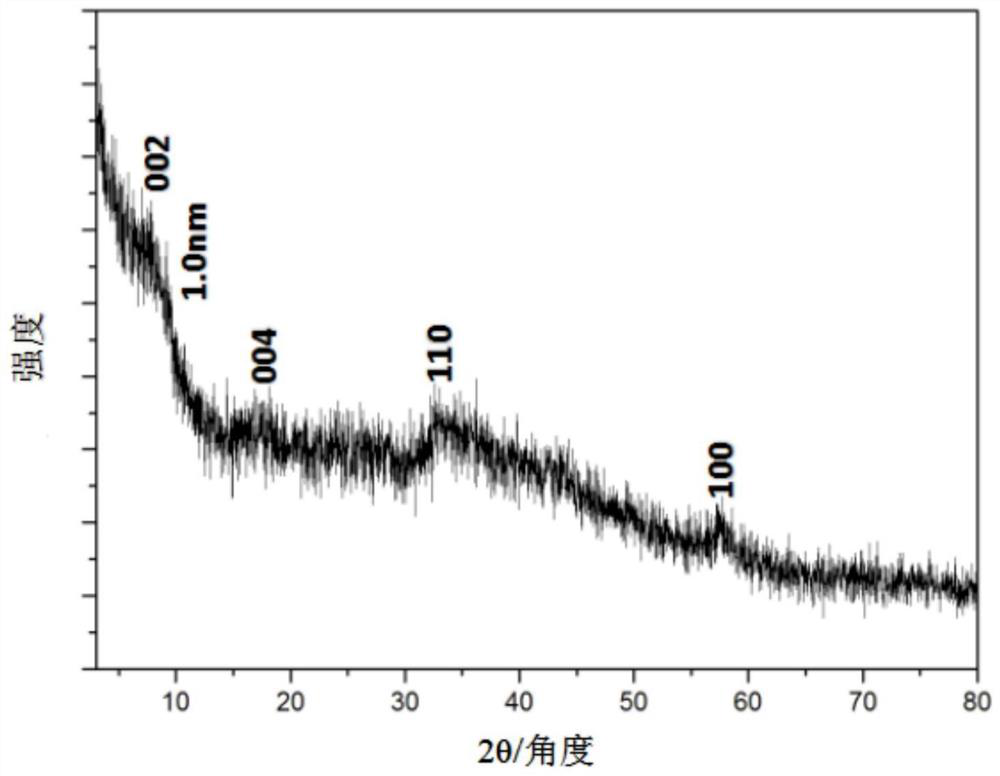

[0040] Weigh 3mmol of sodium molybdate and add it to a 50ml reactor with 30ml of deionized water, then add 18mmol of thiourea and 25mmol of ascorbic acid, stir at room temperature for 30min, then put the reactor into a 210°C oven and heat for 40 hours. Molybdenum disulfide nanomaterials including organic matter intercalation are obtained by filtering and washing, and then calcined at 700° C. for 3 hours to obtain molybdenum disulfide-carbon composite materials. Such as figure 2 The characteristic peaks of the (002) plane and (004) plane shown in the X-ray diffraction diagram of the graph prove that the interlayer spacing of the molybdenum disulfide-graphitized nanocarbon composite is 0.98nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com