A foaming agent for anti-high condensate oil and anti-high salinity and preparation method thereof

A high-salinity, foam-discharging agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor anti-condensate oil and reduced foam performance of foam-discharging agents, and achieve good anti-high Salinity ability, excellent foaming, good resistance to high concentration electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

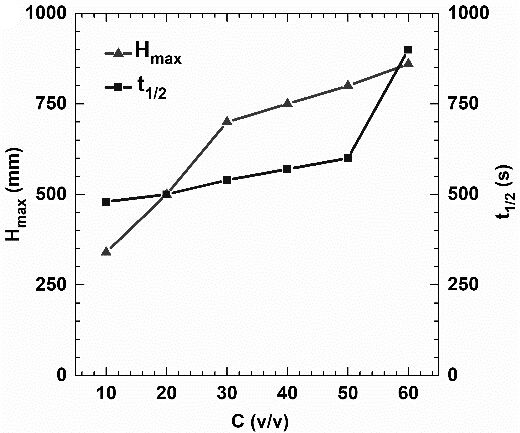

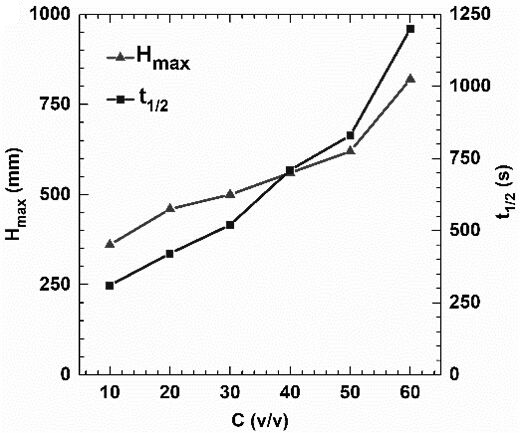

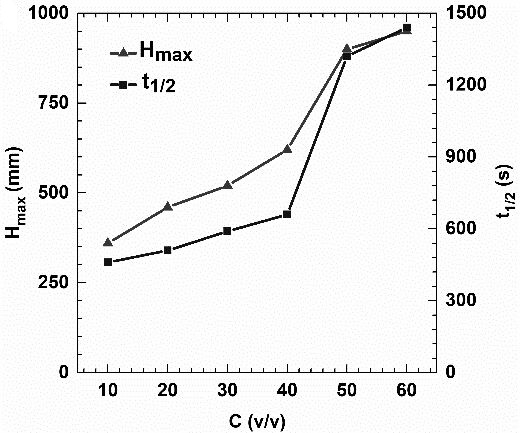

Image

Examples

Embodiment 1

[0058] A foaming agent used to resist high condensate oil and high salinity, in terms of mass percentage, includes the following raw material components:

[0059] Zwitterionic surfactant 20%

[0060] Fluorocarbon Surfactant 1%

[0061] Anionic surfactant 1%

[0062] Coco Monoethanolamide 1%

[0063] The rest is water.

[0064] The zwitterionic surfactant is cocamidopropyl sulfobetaine.

[0065] The fluorocarbon surfactant is perfluorooctanesulfonyl fluoride.

[0066] The anionic surfactant is sodium lauryl sulfate.

[0067] Described water is distilled water.

[0068] A method for preparing a foaming agent for resisting high condensate oil and high salinity, comprising the following steps:

[0069] A. According to proportioning, take by weighing zwitterionic surfactant, fluorocarbon surfactant, anionic surfactant water and coconut oil monoethanolamide respectively;

[0070] B. Put the zwitterionic surfactant, fluorocarbon surfactant and anionic surfactant weighed in ...

Embodiment 2

[0074] A foaming agent used to resist high condensate oil and high salinity, in terms of mass percentage, includes the following raw material components:

[0075] Zwitterionic surfactant 35%

[0076] Fluorocarbon Surfactant 5%

[0077] Anionic surfactant 5%

[0078] Coco Monoethanolamide 5%

[0079] The rest is water.

[0080] The zwitterionic surfactant is cocamidopropyl sulfobetaine.

[0081] The fluorocarbon surfactant is perfluorooctanesulfonyl fluoride.

[0082] The anionic surfactant is sodium lauryl sulfate.

[0083] Described water is distilled water.

[0084] A method for preparing a foaming agent for resisting high condensate oil and high salinity, comprising the following steps:

[0085] A. According to proportioning, take by weighing zwitterionic surfactant, fluorocarbon surfactant, anionic surfactant water and coconut oil monoethanolamide respectively;

[0086] B. Put the zwitterionic surfactant, fluorocarbon surfactant and anionic surfactant weighed in ...

Embodiment 3

[0090] A foaming agent used to resist high condensate oil and high salinity, in terms of mass percentage, includes the following raw material components:

[0091] Zwitterionic surfactant 22%

[0092] Fluorocarbon Surfactant 2%

[0093] Anionic surfactant 5%

[0094] Coco Monoethanolamide 3%

[0095] The rest is water.

[0096] The zwitterionic surfactant is cocamidopropyl sulfobetaine.

[0097] The fluorocarbon surfactant is perfluorooctanesulfonyl fluoride.

[0098] The anionic surfactant is sodium lauryl sulfate.

[0099] Described water is distilled water.

[0100] A method for preparing a foaming agent for resisting high condensate oil and high salinity, comprising the following steps:

[0101] A. According to proportioning, take by weighing zwitterionic surfactant, fluorocarbon surfactant, anionic surfactant water and coconut oil monoethanolamide respectively;

[0102] B. Put the zwitterionic surfactant, fluorocarbon surfactant and anionic surfactant weighed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com