Preparation method of all-solid-waste ecological slope protection brick

An ecological slope protection and brick-laying technology, which is applied in the field of slope protection brick-laying preparation, can solve the problems of preparing slope protection products, and achieve the effect of alleviating the increase in preparation costs, extremely low preparation costs, and high promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

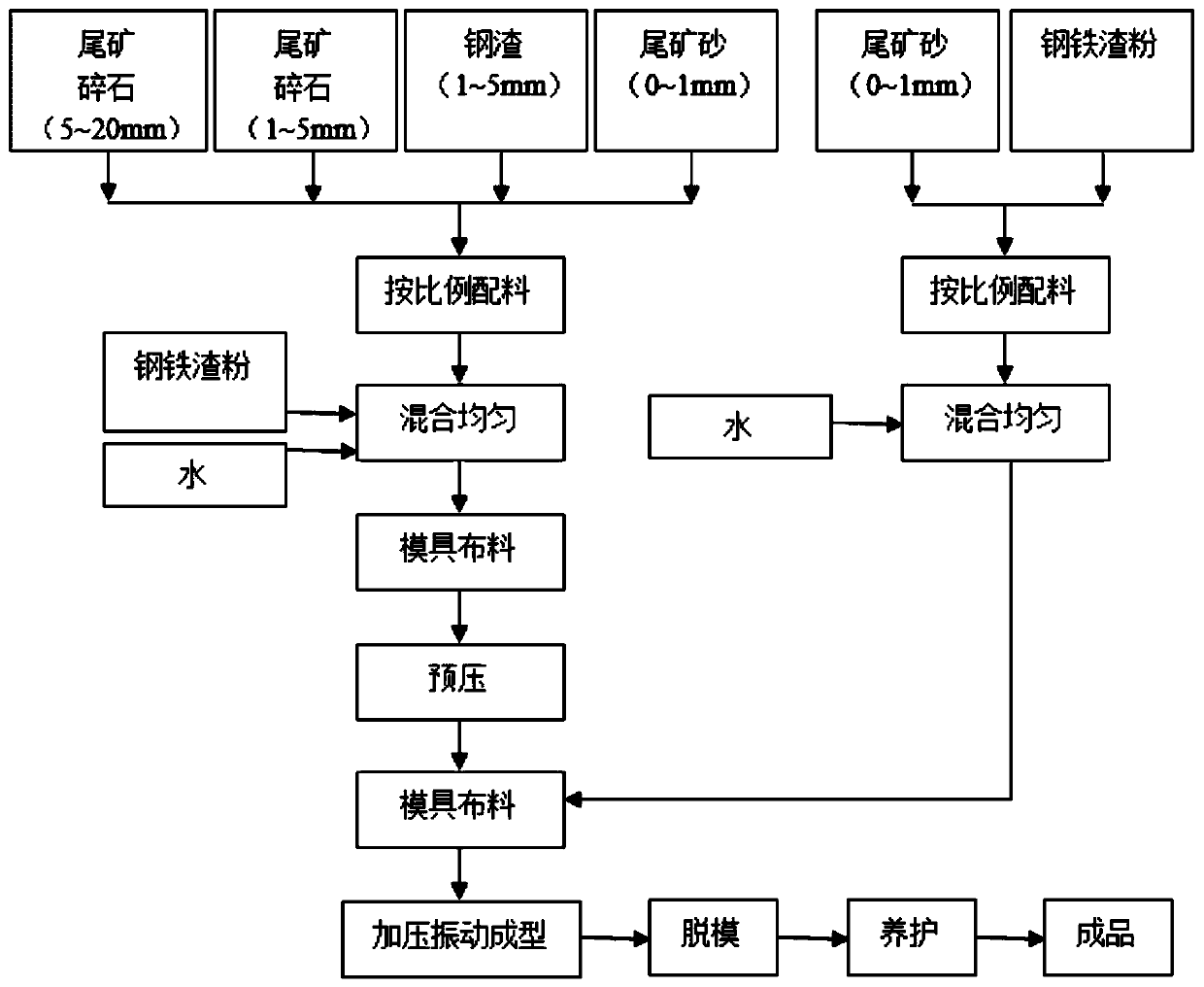

[0035] A method for preparing all solid waste ecological slope protection bricks, which can use all metallurgical solid waste resources to prepare slope protection bricks, greatly reducing the manufacturing cost of slope protection bricks, and the prepared slope protection bricks are stable, freeze-thaw resistant Both performance and erosion resistance can meet the requirements of use. The specific steps and principle of the method will be described in detail below.

[0036] In the preparation process of slope protection bricks, the particle size of the aggregate has a great influence on the performance of the finished slope protection bricks. Aggregate with a larger particle size can increase the strength of the finished slope protection bricks, but it will also increase the brickwork. Porosity reduces its waterproof and freeze-thaw resistance, and the strength of slope protection bricks made of aggregates with smaller particle sizes is difficult to meet the requirements. In...

Embodiment 1

[0053] The steel slag, tailings crushed stone (5-20mm), tailings crushed stone (1-5mm) and tailings sand are batched according to the weight of 840kg, 300kg, 290kg and 620kg respectively and sent to the collecting hopper through the belt, and then passed through the bucket elevator Transfer to a blender. Next, add 340kg of steel slag powder (102kg of steel slag powder, 238kg of slag powder) and 140L of water into the mixer, keep the water-cement ratio at about 0.4, stir while adding water, and unload the material to the conveyor after stirring evenly. The good blank raw materials are loaded into the storage hopper and sent to the silo of the molding machine, and the blank feeding trolley at the silo mouth receives the material. At the same time, send 96kg of steel slag powder (29kg of steel slag powder, 67kg of slag powder) and 288kg of tailing sand into another mixer, add 38L of water, stir until uniform while adding water, and unload to the fabric feeding trolley.

[0054] ...

Embodiment 2

[0058] The steel slag, tailings crushed stone (5-20mm), tailings crushed stone (1-5mm) and tailings sand are batched according to the weight of 720kg, 360kg, 350kg and 620kg respectively and sent into the collecting hopper through the belt, and then passed through the bucket elevator Transfer to a blender. Next, add 350kg of steel slag powder (105kg of steel slag powder, 245kg of slag powder) and 142L of water into the mixer, keep the water-cement ratio at about 0.41, stir while adding water, and unload the material to the conveyor after stirring evenly. The good blank raw materials are loaded into the storage hopper and sent to the silo of the molding machine, and the blank feeding trolley at the silo mouth receives the material. At the same time, send 96kg of steel slag powder (29kg of steel slag powder, 67kg of slag powder) and 288kg of tailing sand into another mixer, add 38L of water, stir until uniform while adding water, and unload to the fabric feeding trolley.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com