Processing method for curved compound metal wallboard hole

A hole processing method and clad metal technology, applied in metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of increased manufacturing cost, unqualified hole processing, long wall plate manufacturing time, etc. Processing efficiency, the effect of solving chip accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

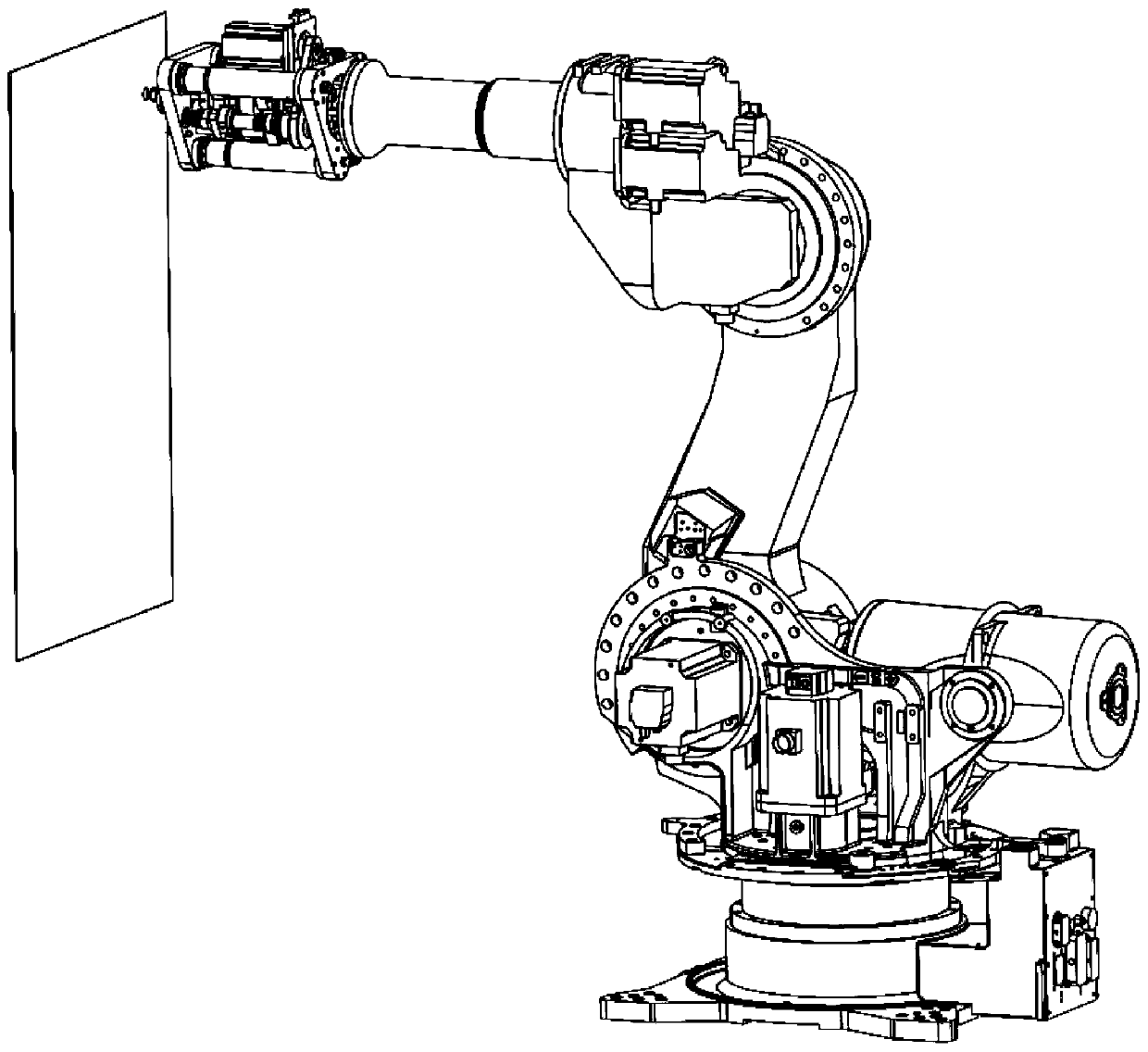

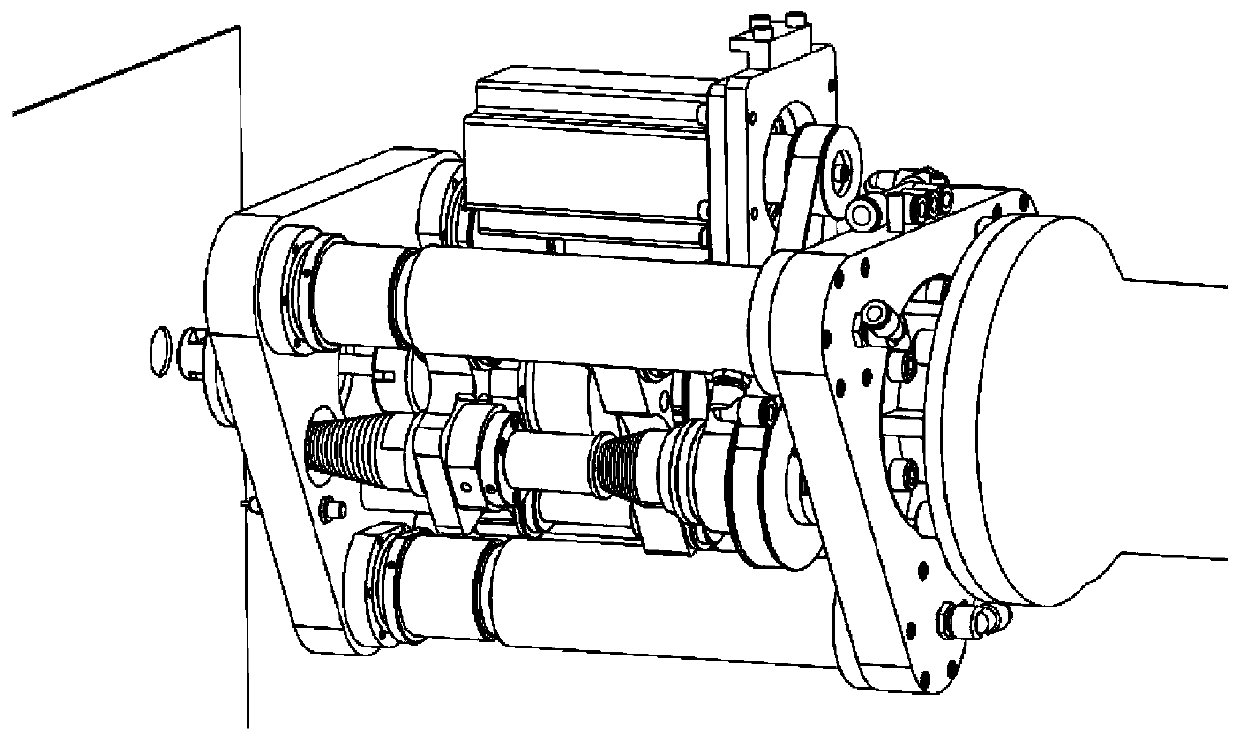

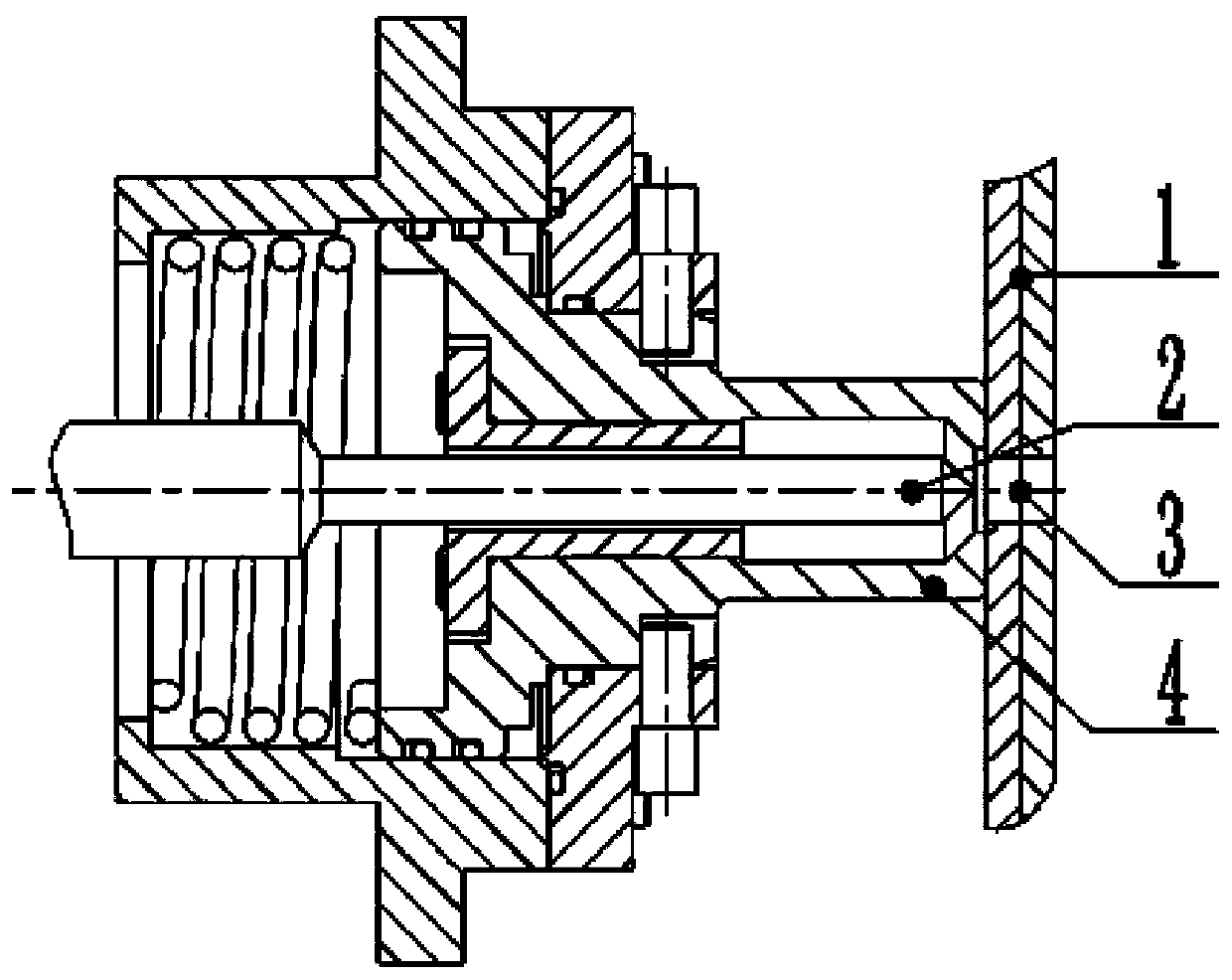

[0028] A method for processing a hole in a curved metal composite wallboard, comprising a titanium alloy wallboard drilling device with a camera installed, and an automatic drilling device fixed on the front end of a robot arm, see Figure 1~3 , which is characterized in that a proprietary processing program for automatic drilling equipment is added to the robot control system, and the NC parameters and macro programs CLAMP / UNCLAMP are set, and the PLC program is logically edited.

[0029] Proprietary processing program

[0030]

[0031] NC parameter setting:

[0032] 10715$MN_M_NO_FCT_CYCLE[7]=86

[0033] 10715$MN_M_NO_FCT_CYCLE[8]=87

[0034] 10716$MN_M_NO_FCT_CYCLE_NAME[7]=CLAMP

[0035] 10716 $MN_M_NO_FCT_CYCLE_NAME[8]=UNCLAMP.

[0036] The macro program CLAMP is as follows:

[0037] PROC TOOL SAVE DISPLOF

[0038] STOPRE

[0039] M86

[0040] G4F1

[0041] M17

[0042] M30.

[0043] The macro program UNCLAMP is as follows:

[0044] PROC TOOL SAVE DISPLOF

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com