Vacuum suction cup holder for automatic plate receiving machine without chipping

A technology of vacuum suction cup and plate receiving machine, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve problems such as line failure, failure to meet the production requirements of clean rooms, and generation of metal debris, so as to achieve the effect of solving chip shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings.

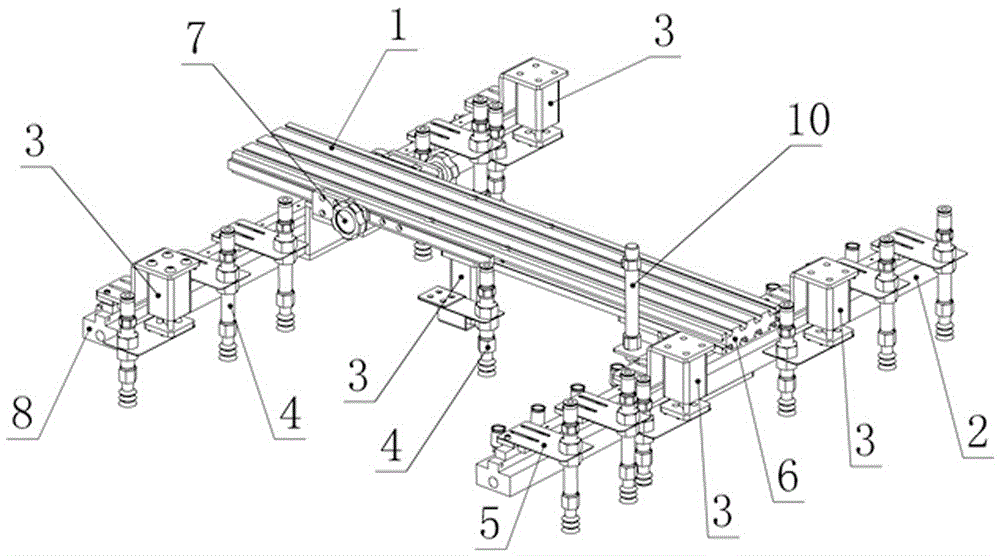

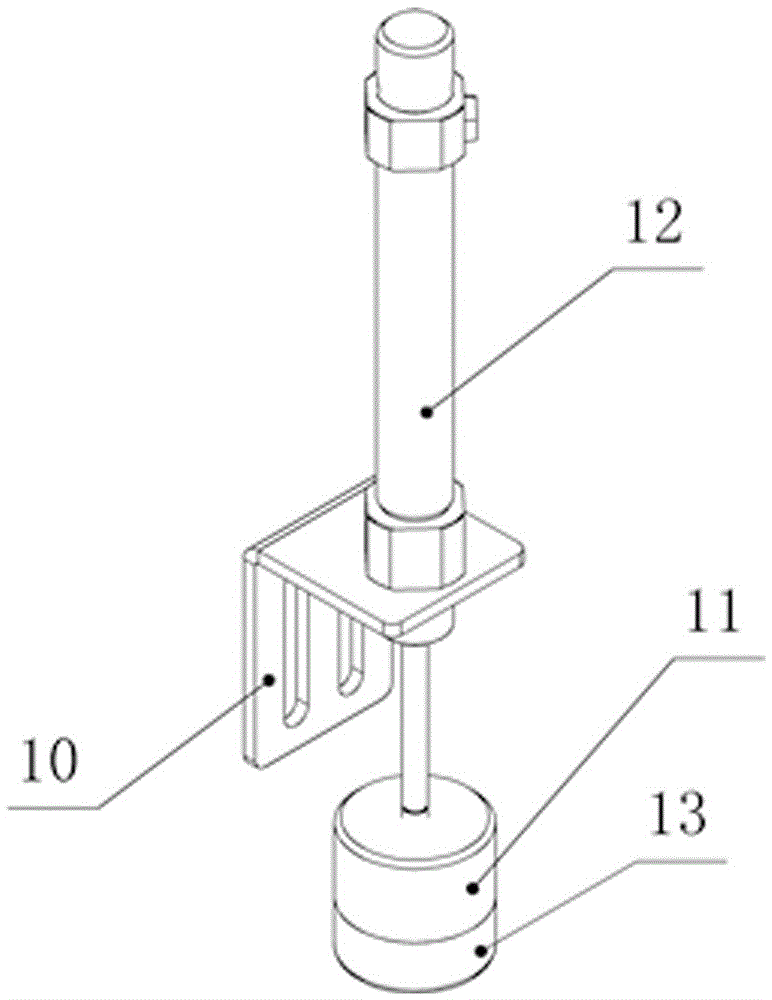

[0015] Such as figure 1 with figure 2 As shown, a vacuum suction cup holder for automatic plate-rewinding machine without chip removal includes a supporting beam 1, a linear guide 2, a shaking cylinder 3, a suction nozzle device 4 and a buffer device 5, and two ends of the supporting beam 1 are fixedly connected to each other. A linear guide 2, linear guide 2 is perpendicular to the support beam 1, one end of the support beam 1 is the fixed end 6, the other end of the support beam 1 is the width adjustment end 7, and the width adjustment end 7 of the support beam 1 is provided with a width adjustment Block, a valve island assembly 8 is provided on the linear guide 2, which is connected to a plurality of suction nozzle devices 4 through a buffer device 5, and two shaking cylinders 3 are fixedly connected to each linear guide 2 through a buffer device 5 A shaking cylinder 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com