Z-axis chip removal structure of horizontal machining center

A Z-axis, horizontal technology, applied in the field of Z-axis chip removal structure, can solve the problems of time-consuming and laborious, low efficiency, incomplete cleaning of waste and other problems, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

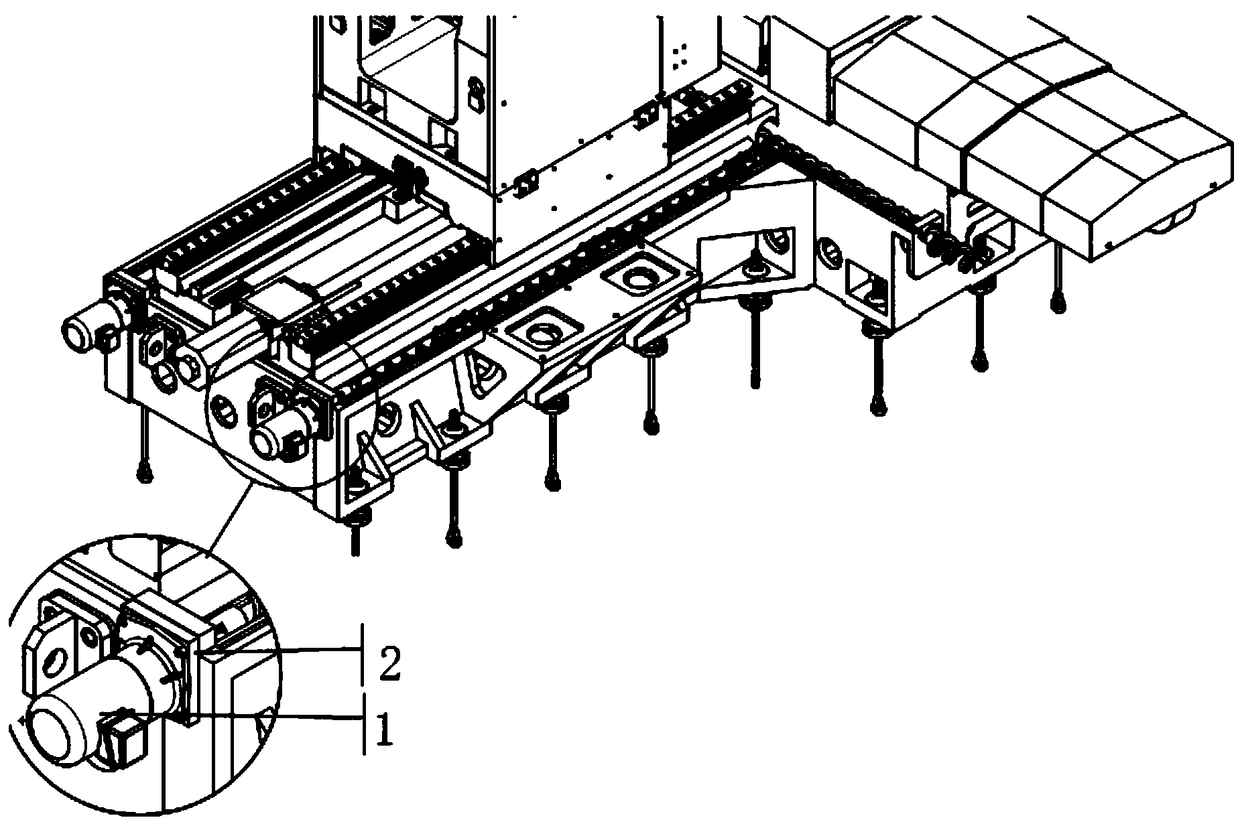

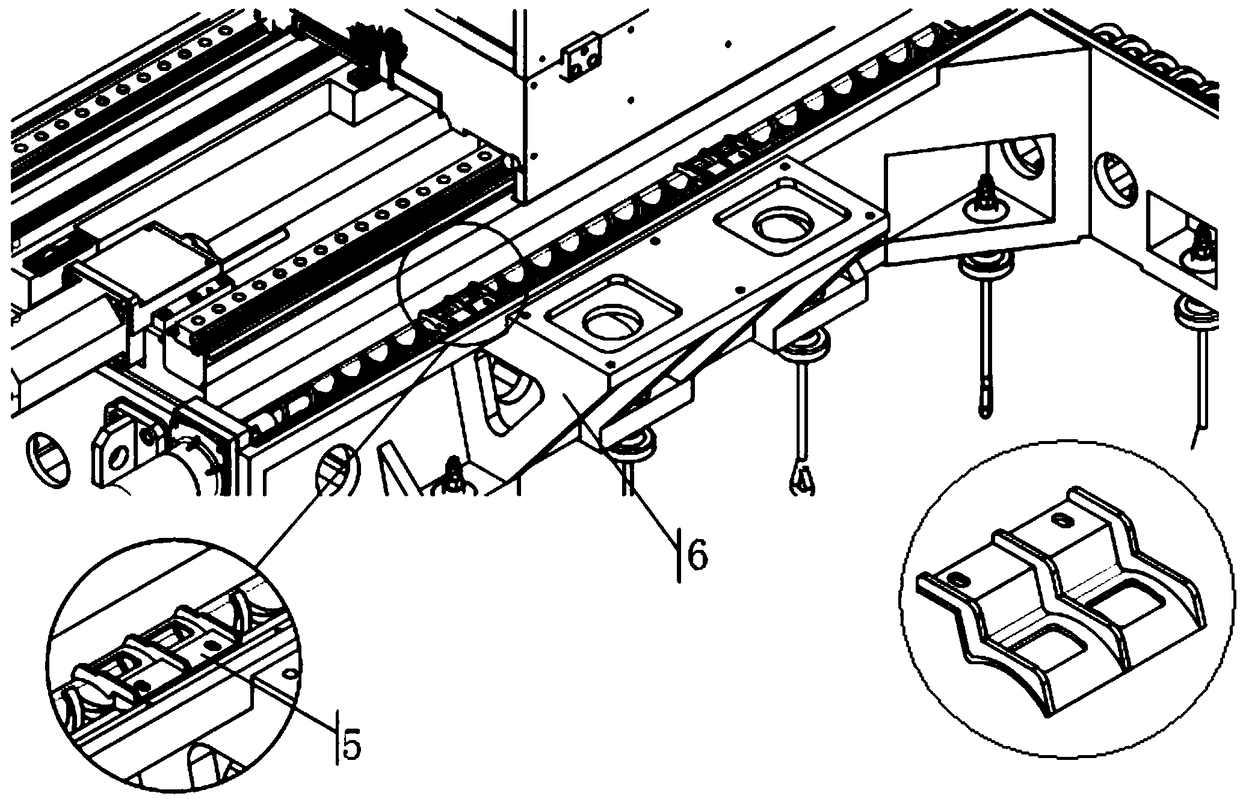

[0014] A Z-axis chip removal structure of a precision horizontal machining center includes a driving part, a chip conveyor (including Jiaolong and a universal joint), and parts of a pressure plate of the chip conveyor.

[0015] Driving part: The driving part is composed of a motor 1 and a motor connecting plate 2. The motor 1 is installed on the motor connecting plate 2, and the motor connecting plate 2 has an open ring groove, and is equipped with an O-ring, which is installed on the outer surface of the bed to avoid damage during processing. Cutting fluid seeps out of the machine tool. The specific installation method is as figure 1 shown.

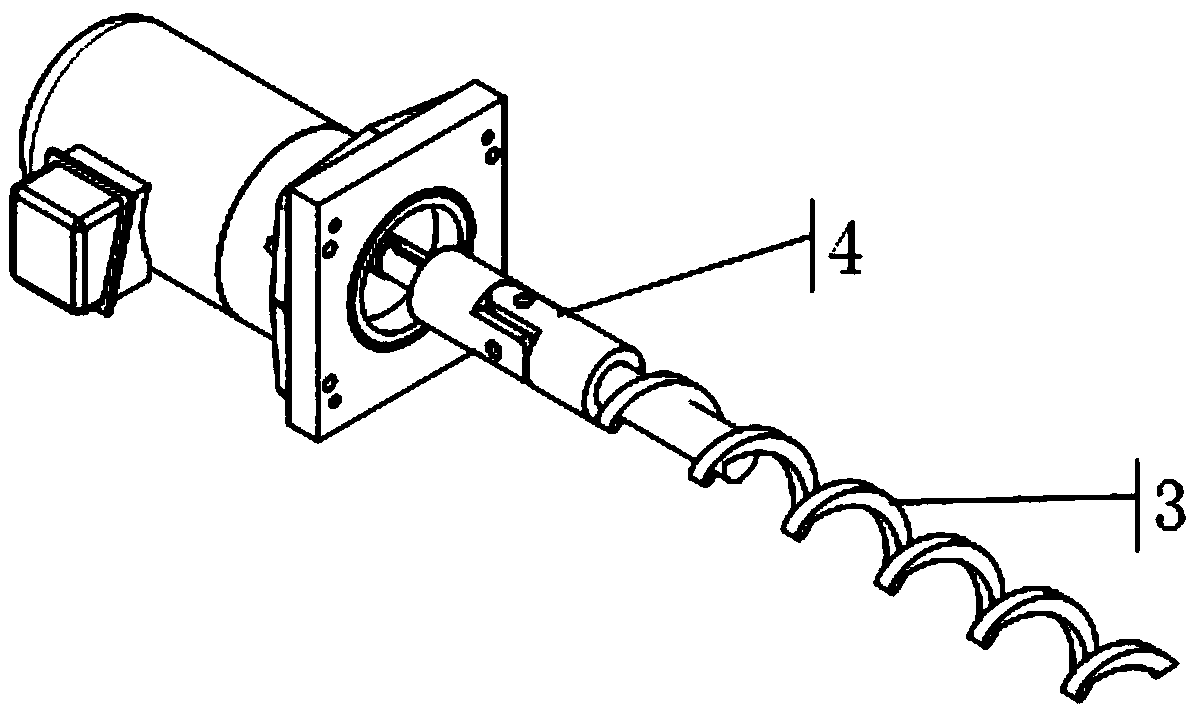

[0016] Spiral chip conveyor (including Jiaolong and universal joint): The spiral chip conveyor is welded by Jiaolong 3 and universal joint in 4 axes. The groove of the chip conveyor is not necessarily flat when the bed is cast, so the universal joint Under the control of 4, it can cooperate with the chip conveyor groove to discharge th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com