Paint spraying device for production of network filters

A network filter and paint technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems that the distance between the paint spraying head and the equipment to be painted cannot be adjusted, and affect the painting process of the equipment, so as to achieve convenient painting treatment, convenient use, and guaranteed painting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

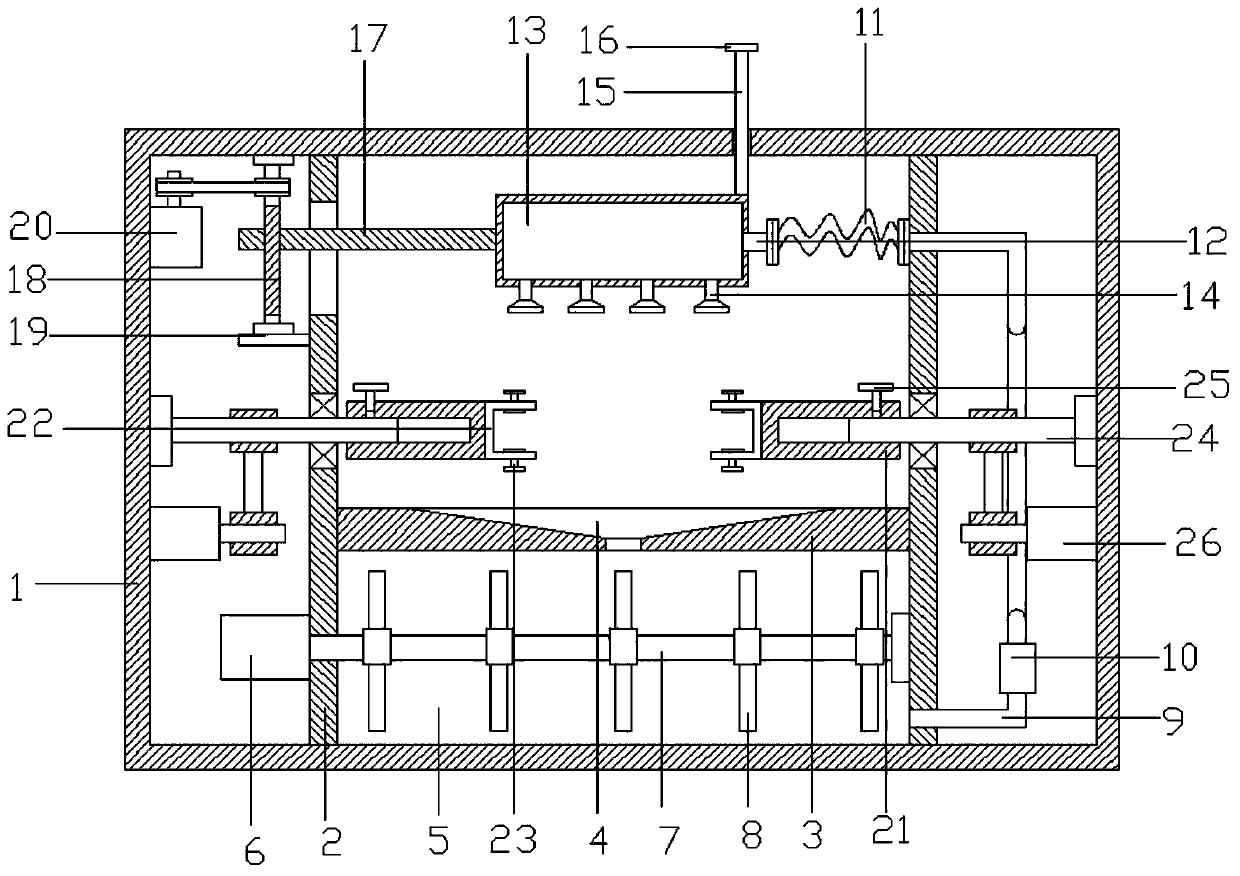

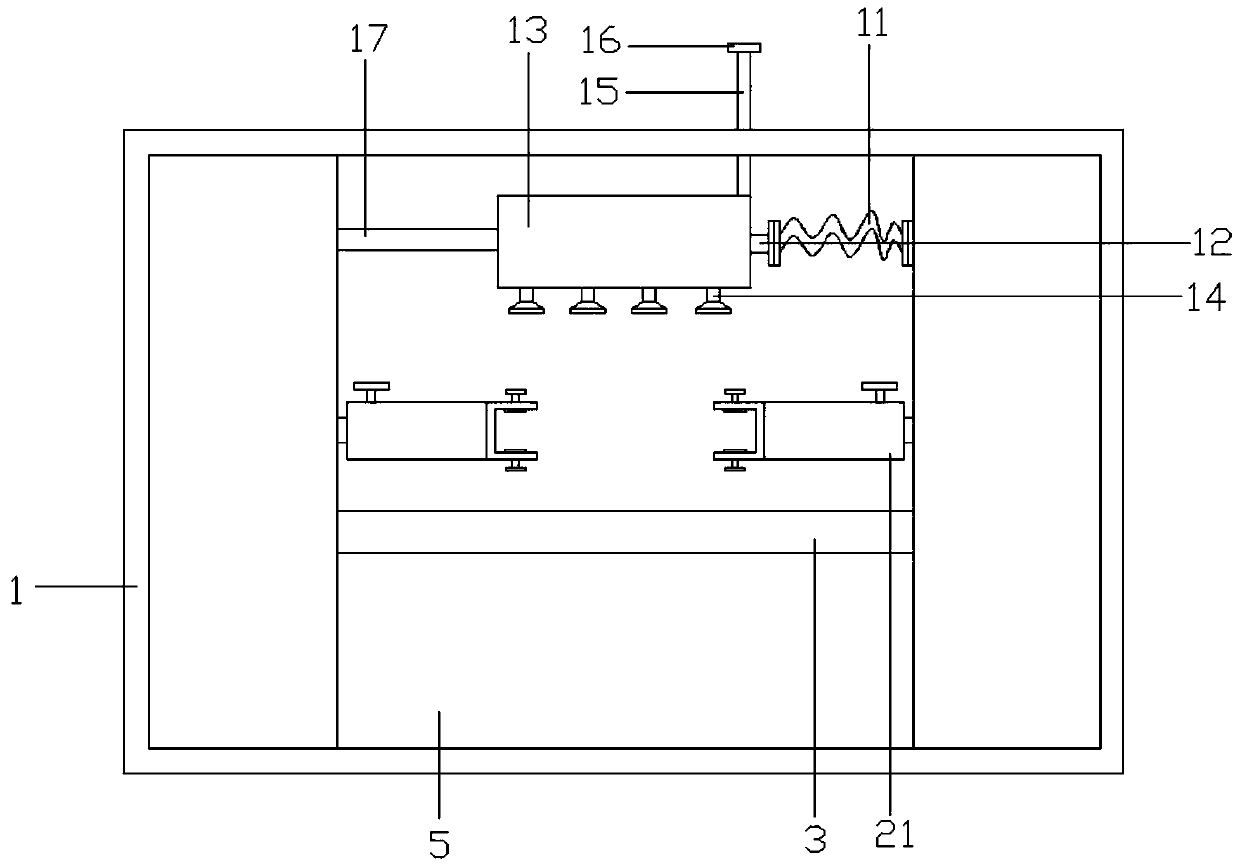

[0025] refer to Figure 1~3 , in an embodiment of the present invention, a painting device for network filter production, including a support frame 1, the left and right ends of the support frame 1 are provided with first partitions 2, and the lower end between the first partitions 2 is provided with a second The partition 3 can divide the support frame 1 into several areas, so as to facilitate the installation of the equipment and the wiring of the equipment, so as to ensure the beauty of the equipment structure and facilitate people's maintenance and treatment. The middle part of the second partition 3 is provided with a drain tank 4. A paint storage chamber 5 is provided on the lower side of the second partition 3, and the drain tank 4 on the second partition 3 can not only facilitate the addition of paint to the inside of the paint storage chamber 5, but also facilitate the redundant waste of the equipment during the painting process. The paint re-enters the interior of th...

Embodiment 2

[0029] The difference from Embodiment 1 is that the upper right end of the connection chamber 13 is provided with a limit rod 15, the limit rod 15 passes through the support frame 1, and a limit block 16 is installed on the limit rod 15 on the upper side of the support frame 1, which can effectively The connection cavity 13 is limited, so that the stability of the connection cavity 13 can be ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com