Research on pure two-dimensional covalent organic framework material membrane for removing liquid-phase antibiotics

A technology for antibiotics and removal, applied in the direction of membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problem that trace organic pollutants cannot be fully eliminated, and achieve fewer steps, high repeatability, and good chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

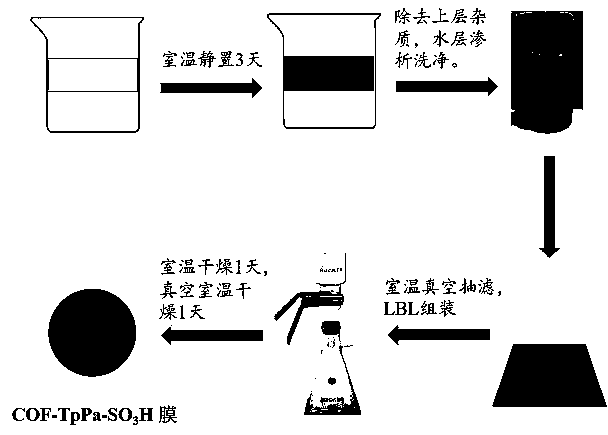

[0031] COF-TpPa-SO synthesized by interfacial polymerization 3 The H nanosheets were washed and collected. Make it evenly disperse into the solution, take a drop of the dispersion and evenly drop it on the silicon wafer, and dry it at 40 °C for 24 h under vacuum.

[0032] Tp and Pa-SO 3The two monomers of H were ultrasonically dissolved into dichloromethane and water solvent respectively, and then adding a regulator (p-toluenesulfonic acid monohydrate) into the water solvent, which will contain Pa-SO 3 The aqueous solution of H was slowly added dropwise to the solution of Tp in dichloromethane. After 3 days of static reaction, the upper aqueous solution was taken, and after dialysis and washing, COF-TpPa-SO 3 H nanosheet aqueous solution, and then disperse it in deionized water to obtain a certain concentration of COF nanosheet solution. Take a drop of COF aqueous solution and drop it on a clean silicon wafer to test the SEM characterization of the nanosheets.

example 2

[0034] The prepared COF membrane was placed in the separation layer, sealed with an O-ring, and then the prepared feed solution was placed on the feed side, and the antibiotic removal performance and water flux of the membrane were tested by a self-made device.

[0035] COF-TpPa-SO 3 The H film was placed in the mold, sealed with an O-ring, and then the configured 400 ppm concentration of cefotaxime solution was placed on the feed side, and the solution was collected on the discharge side. After turning on the vacuum pump, start to record the suction filtration time and the pressure difference between the feed side and the discharge side. After infiltration, record the volume of solution on the infiltration side. Measure the concentration of the solution on the feed side and the discharge side by a UV spectrophotometer, then calculate the removal rate of antibiotics, and then calculate the flux of water based on the solution volume on the discharge side, suction filtration ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com