Water purification and filtration system capable of reducing backwashing water consumption

A technology of backwashing water and filtration system, applied in the directions of filtration separation, filtration loop, separation method, etc., can solve the problems of poor backwashing effect, large backwashing water consumption, incomplete washing of filter tank, etc., to avoid the quality of effluent. Instability, reducing water consumption, avoiding the effect of incomplete rinsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

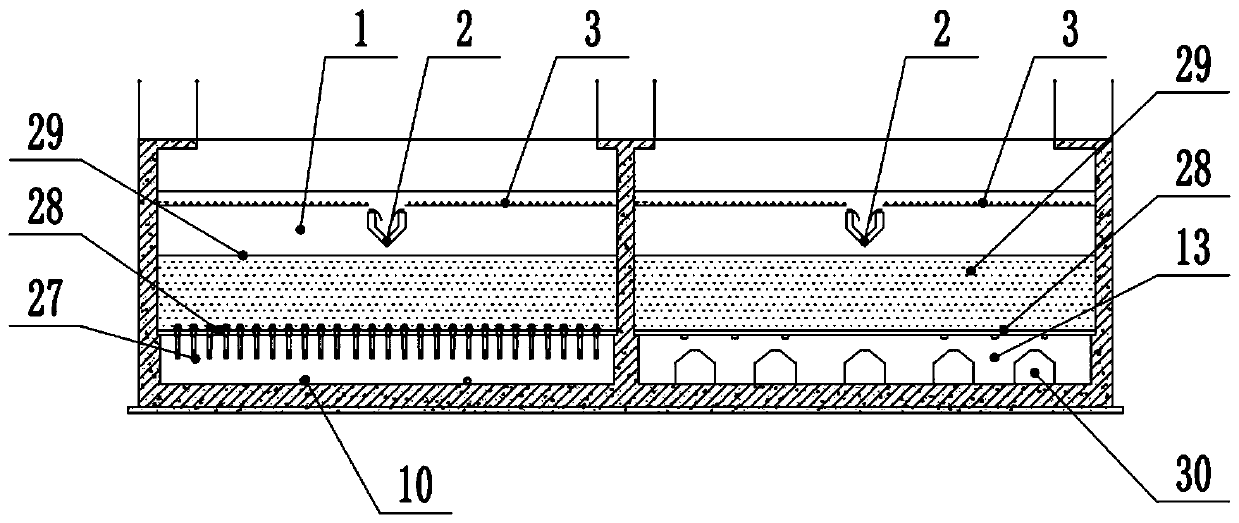

[0026] A water purification and filtration system for reducing backwash water consumption, comprising a filter pool 1, the number of the filter pools 1 is two, and the two filter pools are arranged in parallel; the upper front end of the filter pool 1 is provided with a water inlet pool 9. The lower part of the front end is provided with an empty pool 5; the upper part of the water inlet pool 9 is connected with the water inlet pipe 8 from the sedimentation tank, and the lower part of the water inlet pool 9 is connected with the filter pool 1 through the water inlet butterfly valve 7; the bottom of the empty pool 5 is provided with The drain pipe 12; the bottom of the filter tank 1 is equipped with a filter plate 28 through the filter plate support beam 13 provided with a plurality of uniform water holes 30, and a plurality of short handle filter heads 27 are installed on the filter plate 28, and the top of the filter plate 28 is placed There is a filter material layer 29; a U-...

Embodiment 2

[0032]A water purification and filtration system for reducing backwash water consumption, comprising a filter pool 1, the number of the filter pools 1 is two, and the two filter pools are arranged in parallel; the upper front end of the filter pool 1 is provided with a water inlet pool 9. The lower part of the front end is provided with an empty pool 5; the upper part of the water inlet pool 9 is connected with the water inlet pipe 8 from the sedimentation tank, and the lower part of the water inlet pool 9 is connected with the filter pool 1 through the water inlet butterfly valve 7; the bottom of the empty pool 5 is provided with The drain pipe 12; the bottom of the filter tank 1 is equipped with a filter plate 28 through the filter plate support beam 13 provided with a plurality of uniform water holes 30, and a plurality of short handle filter heads 27 are installed on the filter plate 28, and the top of the filter plate 28 is placed There is a filter material layer 29; a U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com