Method for preparing oligopeptide refreshing beverage by using endogenous endopeptidase and exopeptidase to hydrolyze sesame protein

A technology of refreshing drinks and endopeptidase, which is applied in the field of plant protein processing, can solve the problems of high price of sesame peptide products, increase processing costs, and unfavorable consumer acceptance, so as to achieve high value-added utilization, increase economic value-added, The effect of reducing the cost of enzyme preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Soak 100g of sesame seeds at room temperature for 2 hours, peel off the skin, separate the kernels and skins, wash the peeled sesame seeds, add 500g of water, grind for 2 minutes, and filter to obtain sesame pulp I and sesame residue I; add 200g of water to sesame residue I, grind for 30 seconds, and filter Obtain sesame pulp II and sesame residue II; add 200g water to sesame residue II, grind for 30s, filter to obtain sesame pulp III and sesame residue III; mix sesame pulp I, II and III to obtain sesame pulp IV; centrifuge at 4000rpm for 15min, A light phase, an intermediate phase and a heavy phase are obtained. The protein concentration in the interphase is approximately 0.5%.

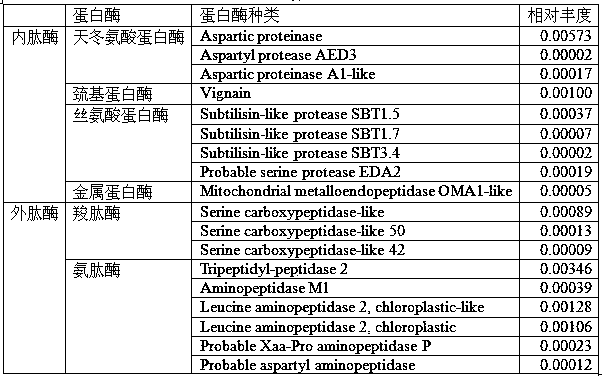

[0023] The types and relative abundances of endopeptidases and exopeptidases in the mesophase were analyzed, and the specific results are shown in Table 1.

[0024] Relative abundance is calculated from the LC-MS / MS signal intensities of all proteins (including enzymes) in the mesophase. Rel...

Embodiment 2

[0036]According to the method of Example 1, the intermediate phase was divided into two parts, intermediate phase I and II; the pH of intermediate phase I and II was adjusted to 4 with malic acid; intermediate phase I was hydrolyzed at 50 ° C for 8 hours, and intermediate phase II was ℃ hydrolysis 8h. The content of oligopeptides was determined according to the above method, and the oligopeptides in mesophase I and II accounted for 76% and 65% of the total protein content, respectively, indicating that higher temperature (60°C) was not suitable for the formation of oligopeptides.

Embodiment 3

[0038] The intermediate phase was prepared by the same method as in Example 1. The intermediate phase is divided into 4 parts, intermediate phase I, II, III and IV; the following hydrolysis process is all carried out at 40°C; the pH of the intermediate phase I is adjusted to 4 with malic acid, and hydrolyzed for 4h and 8h; Adjust the pH of phase II to 5, hydrolyze for 4h and 8h; use malic acid to adjust the pH of intermediate phase III to 4, hydrolyze for 4h, then use baking soda to adjust the pH of intermediate phase III to 5, and then hydrolyze for 4h; use malic acid Adjust the pH of the intermediate phase IV to 5, hydrolyze for 4 hours, then use malic acid to adjust the pH of the intermediate phase IV to 4, and then hydrolyze for 4 hours.

[0039] The content of oligopeptides was determined according to the method described above (Table 3). At 40℃, 4h hydrolysis can reach a higher oligopeptide content; continue hydrolysis for 4h, especially in the case of adjusting the pH,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com