A circuit board drilling aid

A technology for auxiliary devices and circuit boards, which is applied in the direction of printed circuits, printed circuit manufacturing, and electrical components. The effect of shifting, prolonging service life and improving drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

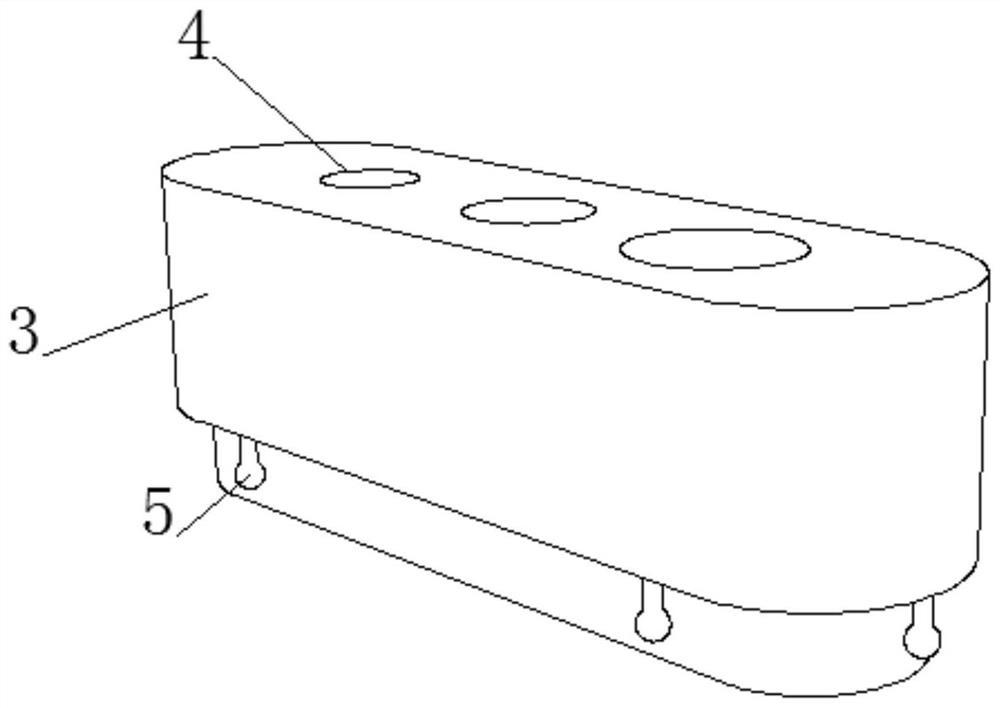

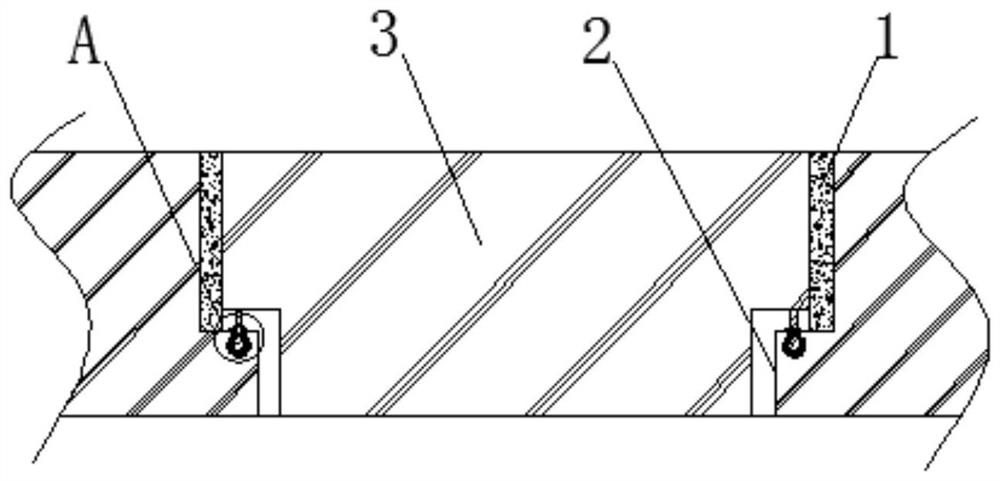

[0047] see Figure 1-3 , a circuit board drilling auxiliary device, including the auxiliary device body installed on the drilling machine tool, the drill on the work table of the drilling machine tool can help drill long holes 2, the auxiliary device body matches the auxiliary drilling long holes 2, and assists in drilling The device body includes an elongated auxiliary drill block 3, and the elongated auxiliary drill block 3 is located in the long hole 2 of the drilling aid, and the shapes of the long hole 2 and the elongated auxiliary drill block 3 are both inverted convex, and the elongated auxiliary drill block 3. There are multiple positioning and zooming holes 4 excavated at the upper end. The multiple positioning and zooming holes 4 are different in size, and the multiple positioning and zooming holes 4 are respectively matched with drill bits of different specifications. The lower end of the long auxiliary drill block 3 is fixedly connected with multiple special-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com