Mask plate and preparation method for color film substrate

A color filter substrate and mask technology, which is applied to the photoengraving process of the pattern surface, the original for photomechanical processing, optics, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

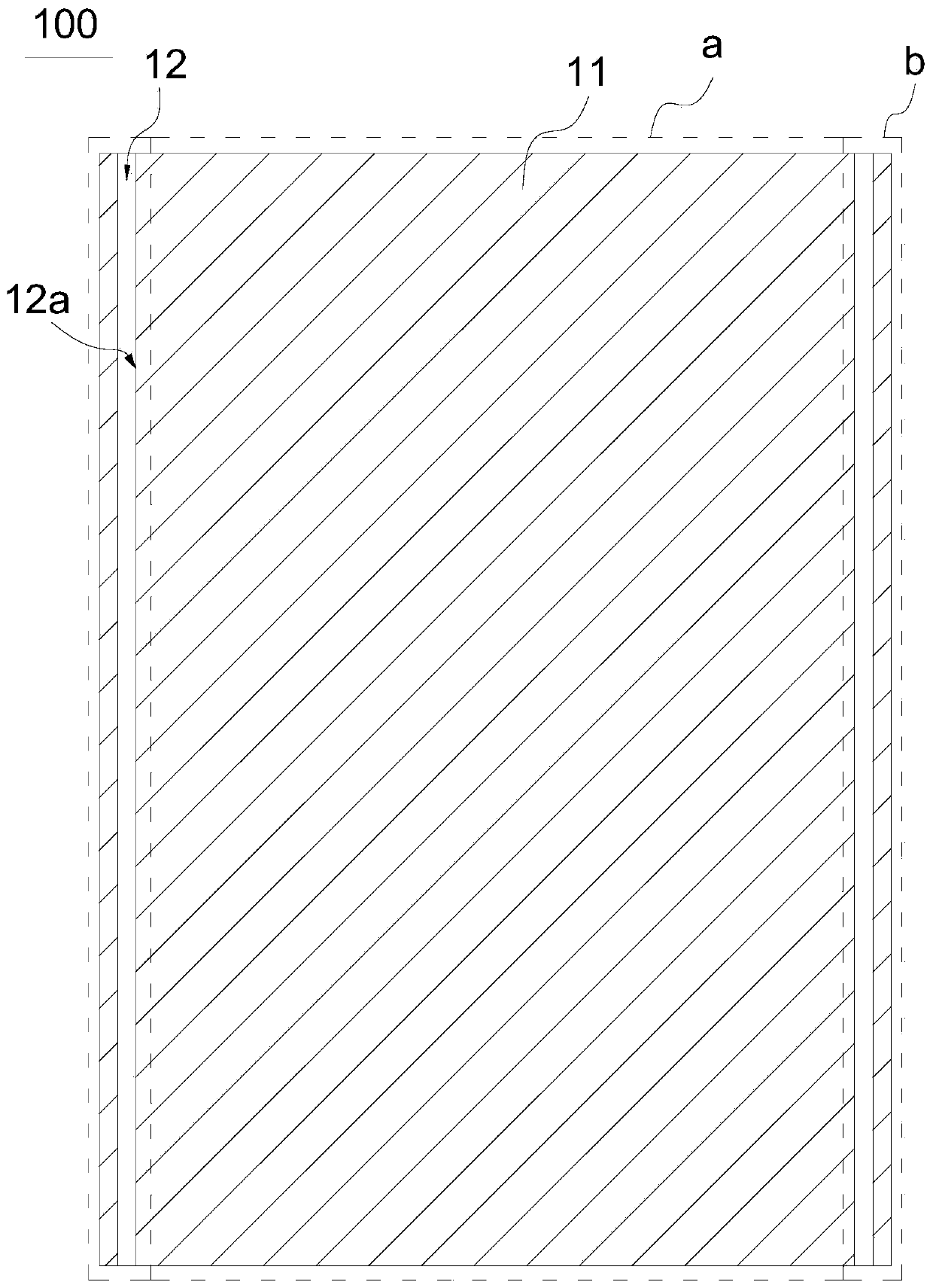

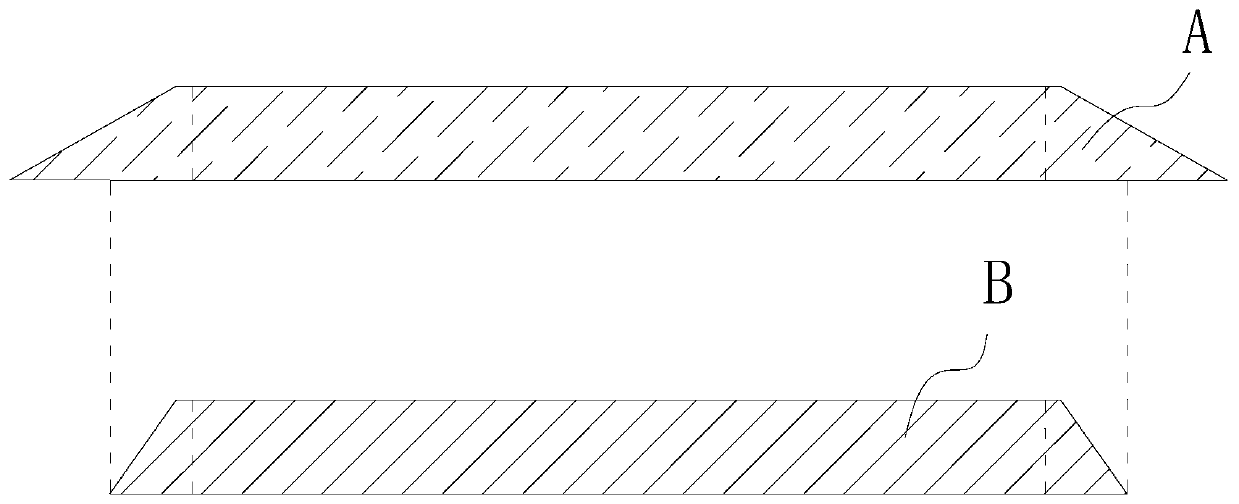

Image

Examples

preparation example Construction

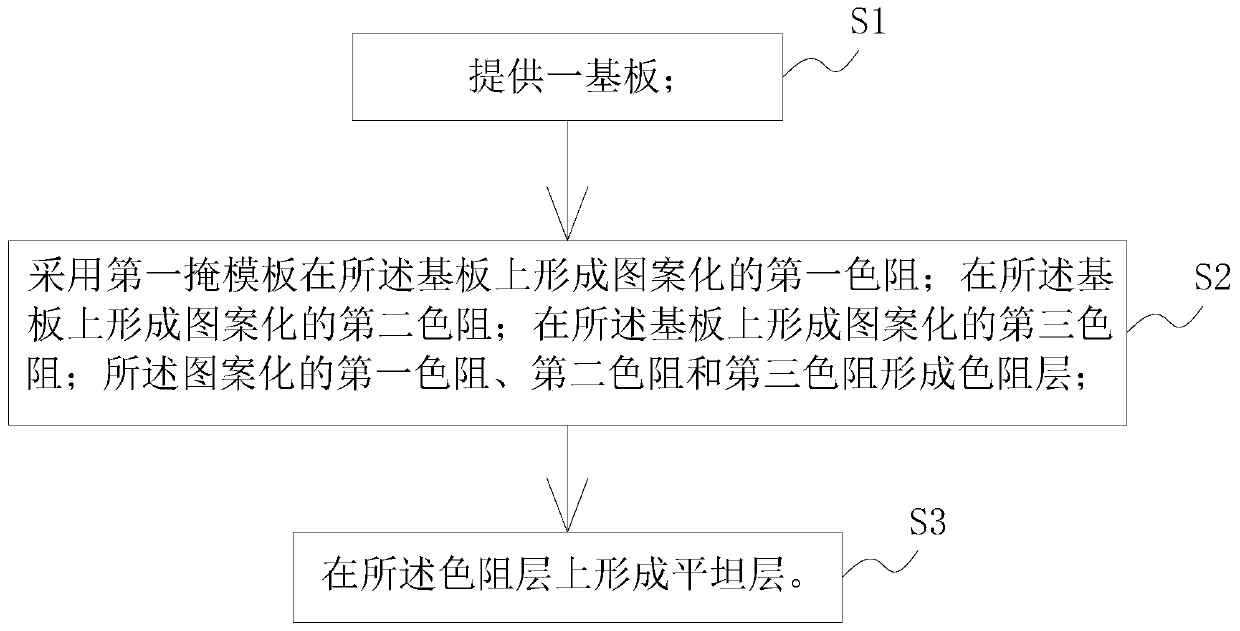

[0038] Please refer to image 3 with Figure 4 , image 3 It is a schematic flow chart of the method for preparing the color filter substrate according to the embodiment of the present application; Figure 4 It is another schematic flowchart of the manufacturing method of the color filter substrate according to the embodiment of the present application. The embodiment of the present application also relates to a method for preparing a color filter substrate, which includes the following steps:

[0039] S1: providing a substrate;

[0040] S2: using a first mask to form a patterned first color-resist on the substrate; forming a patterned second color-resist on the substrate; forming a patterned third color-resist on the substrate; The patterned first color resistance, second color resistance and third color resistance form a color resistance layer; the first mask plate includes a first pattern part corresponding to the first color resistance, and the first pattern part Comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com