Safe and reliable whole factory public water supply method and system

A water supply system and public technology, applied in the field of water conservancy and hydropower engineering, can solve problems such as leakage, difficulty in power station operation and maintenance, and inability to cut off water flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

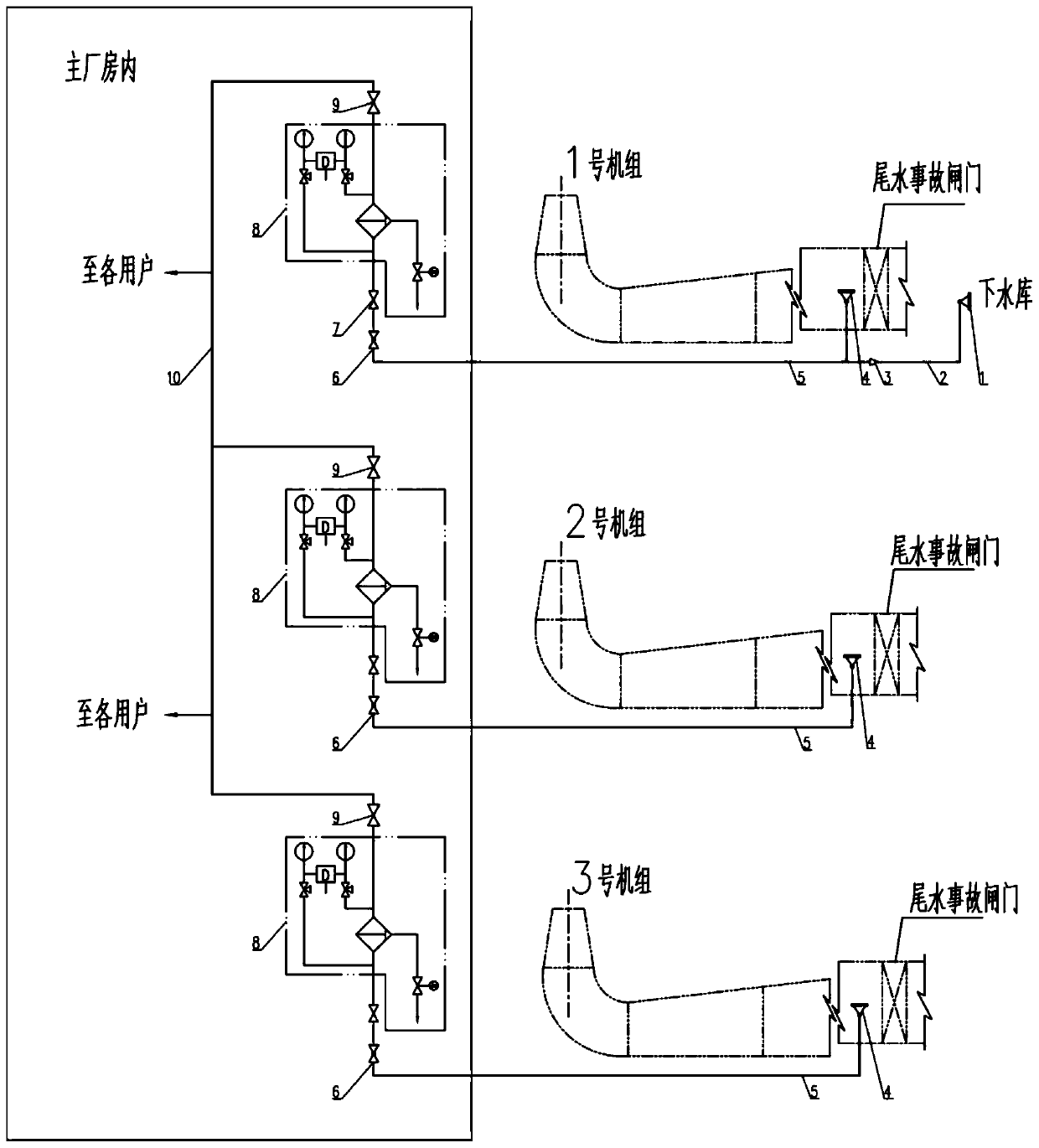

[0018] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

[0019] A safe and reliable public water supply system for the whole plant, including an initial water supply unit and at least one post water supply unit. In this embodiment, two post water supply units are set, and the initial water supply unit and the post water supply unit respectively correspond to a power station unit. The initial water supply unit and the later water supply unit are connected by the water supply main pipe 10 and provided to various users, each user includes: some intermittent water users in the factory building that do not allow the water pressure to be too high (such as SFC coolers, water-cooled air compressor coolers, Air-conditioning coolers in underground workshops, no-load water supply for main transformers, etc.)

[0020] The initial water supply unit includes the water intake 1 in the lower reservoir connected by pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com