A kind of self-emulsifying epoxy resin emulsion and its preparation method and application

A technology of epoxy resin emulsion and epoxy resin, applied in the direction of epoxy resin coating, coating, anti-corrosion coating, etc., can solve the problems of poor storage stability, poor anti-corrosion performance, easy cracking of paint film, etc., and achieve long storage period, Effects of zero VOC emission, excellent paint film toughness and antirust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

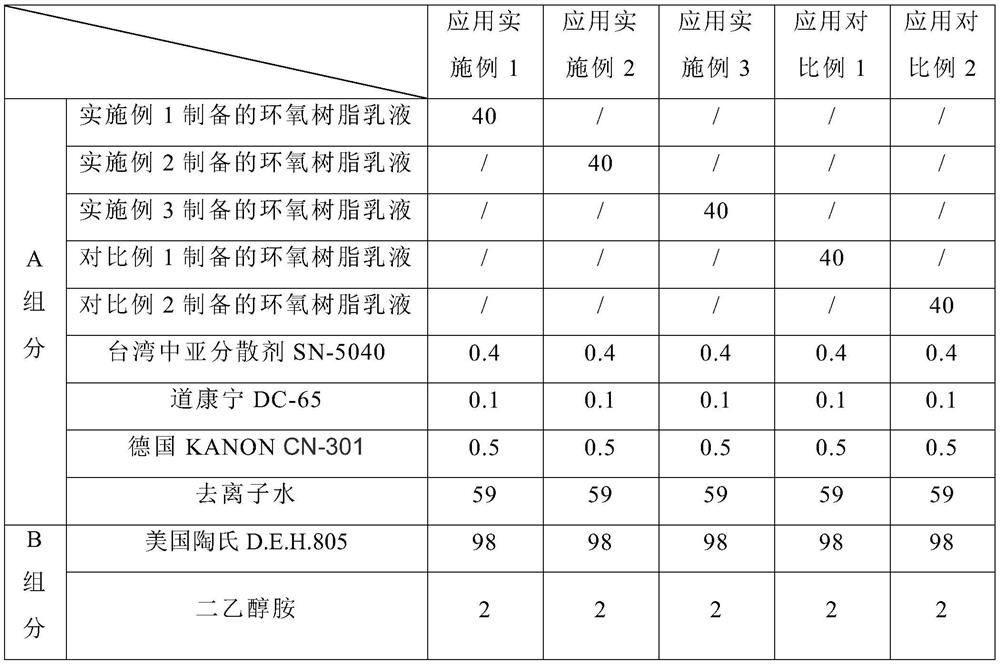

Embodiment 1

[0047] This example provides a self-emulsifying epoxy resin emulsion, in parts by mass, its raw materials include 100 parts of bisphenol A epoxy resin E-44, 30 parts of bisphenol A epoxy resin E12, 10 parts of Tween 20, 10 parts Parts of polyoxyethylene lauryl ether (n=3) phosphate ester, 5 parts of diethanolamine and 300 parts of deionized water.

[0048] The preparation method is as follows:

[0049] (1) Heat bisphenol A epoxy resin E-44, bisphenol A epoxy resin E12 and Tween 20 to about 120°C, then remove moisture in a vacuum, and protect with nitrogen;

[0050] (2) Diethanolamine is added into the mixed solution of dehydrated bisphenol A epoxy resin E-44, bisphenol A epoxy resin E12 and Tween 20, then the temperature is raised, and the temperature is controlled to react at about 185°C;

[0051] (3) Cool down to about 80°C, add polyoxyethylene lauryl ether (n=3) phosphate to react, then slowly add the reaction product into deionized water under stirring conditions, control...

Embodiment 2

[0053] This example provides a self-emulsifying epoxy resin emulsion, in parts by mass, its raw materials include 100 parts of bisphenol A epoxy resin E-51, 20 parts of bisphenol A epoxy resin E12, 10 parts of Tween 80, 10 parts Parts of polyoxyethylene lauryl ether (n=3) phosphate, 5 parts of diethanolamine and 400 parts of deionized water.

[0054] The preparation method is as follows:

[0055] (1) Heat bisphenol A epoxy resin E-51, bisphenol A epoxy resin E12 and Tween 80 to about 120°C, then remove moisture in a vacuum, and protect with nitrogen;

[0056] (2) Add diethanolamine into the mixed solution of dehydrated bisphenol A epoxy resin E-51, bisphenol A epoxy resin E12 and Tween 80, then heat up, and control the temperature to react at about 185°C;

[0057] (3) Cool down to about 80°C, add polyoxyethylene lauryl ether (n=3) phosphate to react, then slowly add the reaction product into deionized water under stirring conditions, control the temperature of the emulsion to a...

Embodiment 3

[0059] This example provides a self-emulsifying epoxy resin emulsion. In terms of parts by mass, its raw materials include 100 parts of bisphenol A epoxy resin E-44, 30 parts of bisphenol A epoxy resin E12, 10 parts of Tween 60, 15 Parts of lauryl polyoxyethylene ether (AE06) phosphate, 5 parts of diethanolamine and 400 parts of deionized water.

[0060] The preparation method is as follows:

[0061] (1) Heat bisphenol A epoxy resin E-44, bisphenol A epoxy resin E12 and Tween 60 to 110-130°C, then vacuum remove moisture, and protect with nitrogen;

[0062] (2) Diethanolamine is added into the mixed solution of dehydrated bisphenol A epoxy resin E-44, bisphenol A epoxy resin E12 and Tween 60, then heat up, and control the temperature to react at about 185°C;

[0063] (3) Cool down to about 80°C, add lauryl alcohol polyoxyethylene ether (AE06) phosphate to react, then slowly add the reaction product into deionized water under stirring conditions, control the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com