Production process of diethylenetriaminepenta(methylene-phosphonic acid)

A technology of diethylenetriamine pentamethylene phosphonic acid and diethylenetriamine, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve unfavorable industrial production of DTPMPA, Increase the content of by-product hydroxymethylphosphonic acid, increase the relative rate of side reactions, etc., to achieve the effects of shortening the total reaction time, inhibiting the production of by-product hydroxymethylphosphonic acid, and improving conversion rate and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

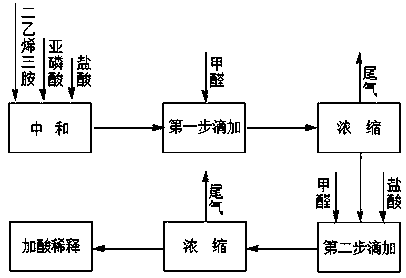

Image

Examples

Embodiment 1

[0024] Add 2813Kg of phosphorous acid aqueous solution with a mass fraction of 71.25% and 2250Kg of hydrochloric acid with a mass fraction of 31.50% into the reactor in sequence, start the stirring and tail gas recovery device, then slowly add 500.0Kg of diethylenetriamine dropwise to the reactor, and the temperature in the reactor is controlled Below 50°C, after the neutralization reaction is completed, heat up to keep the temperature in the reactor at 115±2°C, set and automatically control the formaldehyde drop rate: 250Kg / h for 0.5 hours, 500Kg / h for 0.5 hours , 1000Kg / h was added dropwise to the end of the first stage, and a total of 1573Kg of formaldehyde solution with a mass content of 40.73% was added dropwise. After 1 hour of heat preservation and reaction at 115±2°C, it was evaporated and concentrated to near dryness under normal pressure and then negative pressure conditions; stop negative pressure pressure, and add 225Kg hydrochloric acid to the system, control the s...

Embodiment 2

[0026] Add 2703Kg of phosphorous acid aqueous solution with a mass fraction of 70.69% and 2441Kg of hydrochloric acid with a mass fraction of 32.66% into the reactor in sequence, start the stirring and tail gas recovery device, then slowly add 500.0Kg of diethylenetriamine dropwise to the reactor, and the temperature in the reactor is controlled Below 50°C, after the neutralization reaction is completed, heat up to keep the temperature in the reactor at 115±2°C, set and automatically control the formaldehyde drop rate: 250Kg / h for 0.5 hours, 500Kg / h for 0.5 hours , 1000Kg / h was added dropwise to the end of the first stage, and a total of 1716Kg of formaldehyde solution with a mass content of 40.73% was added dropwise. After 1 hour of heat preservation and reaction at 115±2°C, it was evaporated and concentrated to near dryness under normal pressure and then negative pressure conditions; stop negative pressure Pressure, and add 225Kg hydrochloric acid to the system, control the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com