Outer bag film used for personal-care supplies and packaging bag using outer bag film

A personal care and packaging bag technology, applied in the field of care product packaging, can solve the problems of poor tear resistance and durability, lack of covering, and intrusion of care products, so as to block deliquescence and oxidation, and improve tear resistance. , the effect of prolonging the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

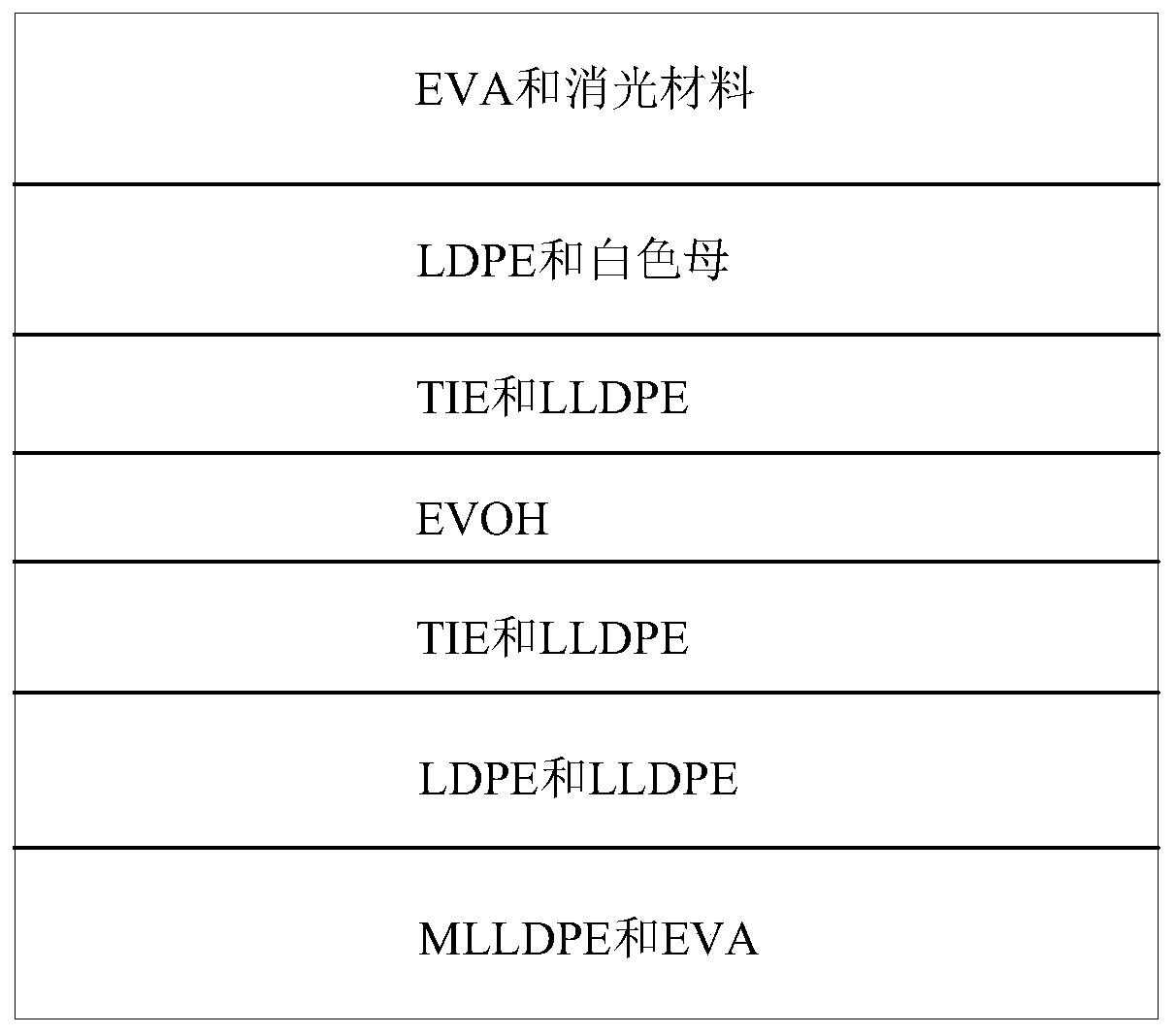

[0045] Such as figure 1 Shown is a personal care product outer bag film with a film thickness of 30 μm according to the present invention, which sequentially includes a matting layer, a covering layer, an upper adhesive layer, a high barrier layer, a lower adhesive layer, a water-blocking layer, heat seal layer;

[0046] Wherein, the raw material of the matting layer is a mixture of EVA and matting materials, and the thickness is 18% of the total film thickness. The addition of matting materials makes the surface layer have a matte effect and has good flexibility, so that the outer bag film is more marketable. ;

[0047] The raw material of the cover layer is a mixture of LDPE and white masterbatch, and the thickness is 17% of the total film thickness. Since personal care products are commodities with privacy, the design of the cover layer can well cover the products contained therein, thus effectively It prevents embarrassment when customers choose and carry;

[0048] The ...

Embodiment 2

[0063] Compared with Example 1, the only difference is that a personal care product outer bag film with a film thickness of 40 μm was prepared. same.

Embodiment 3

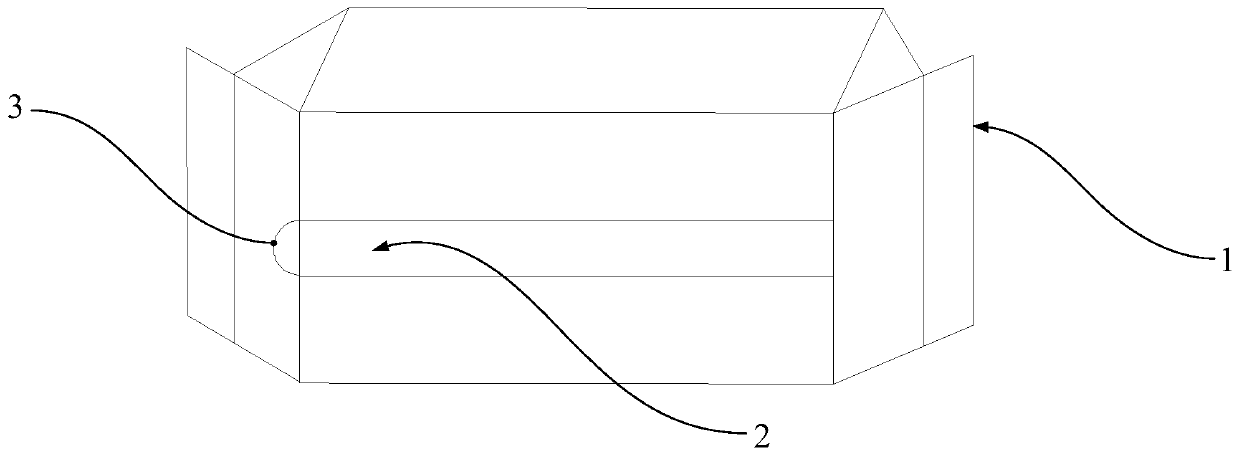

[0065] Compared with the difference of Example 1, the only difference is: the raw material of the heat-sealing layer is Surlyn and EVA mixed in a mass ratio of 7:3, and all the others are the same as in Example 1, such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com