Steel plate side edge rust removal device and method

A technology of steel plate and storage table, which is applied in the direction of grinding drive device, grinding automatic control device, grinding machine, etc., can solve the problems of wasting equipment power consumption, environmental pollution, reducing the efficiency and output of steel rust removal, etc., and achieve the improvement of product qualification High efficiency and production efficiency, ensuring the correctness of stability and direction, real-time and efficient brushing effect on the side of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0061] It should be noted that the orientation words involved in the present invention, such as left and right, etc., are based on the appended Figure 5 The placement state is described.

Embodiment

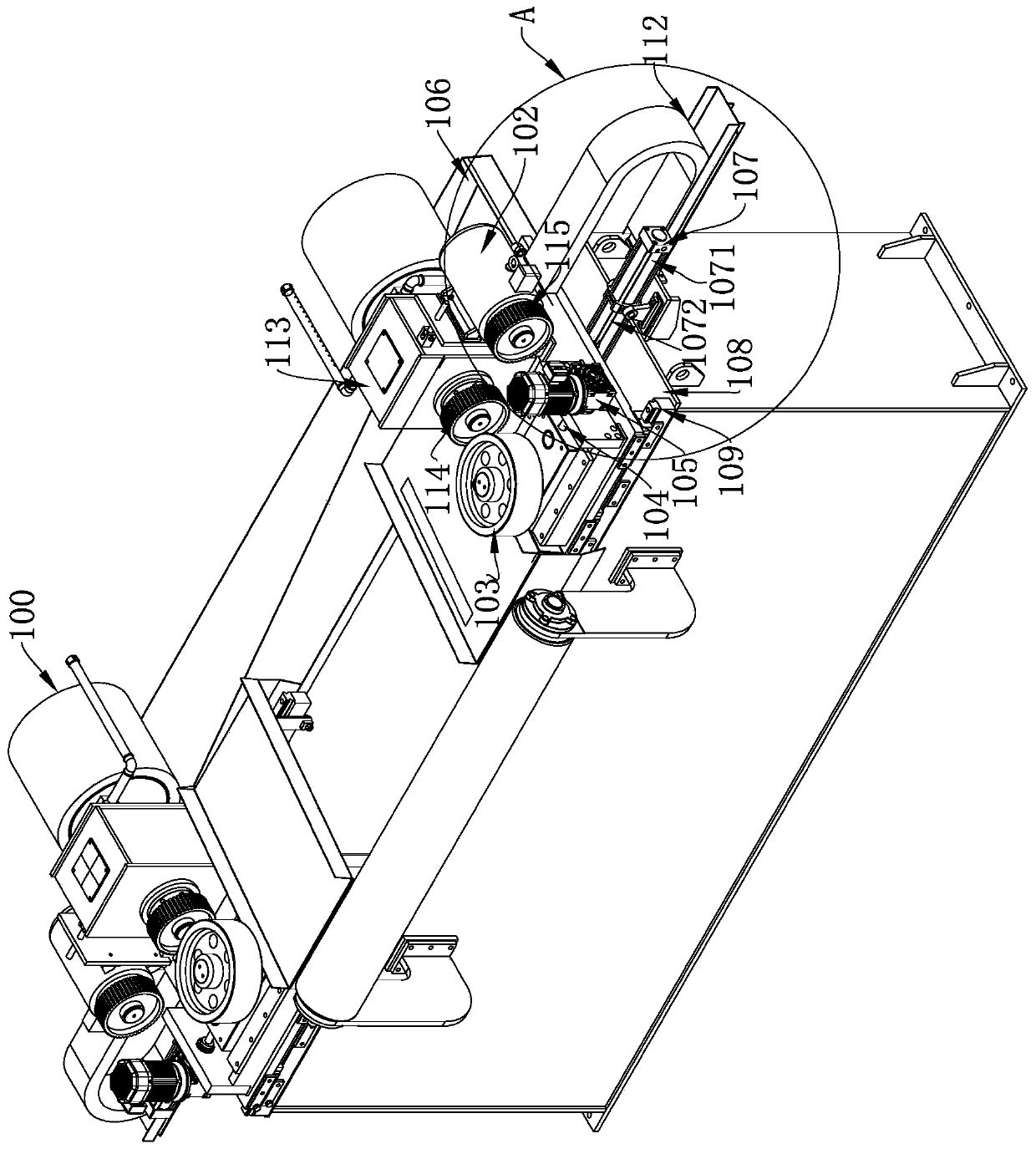

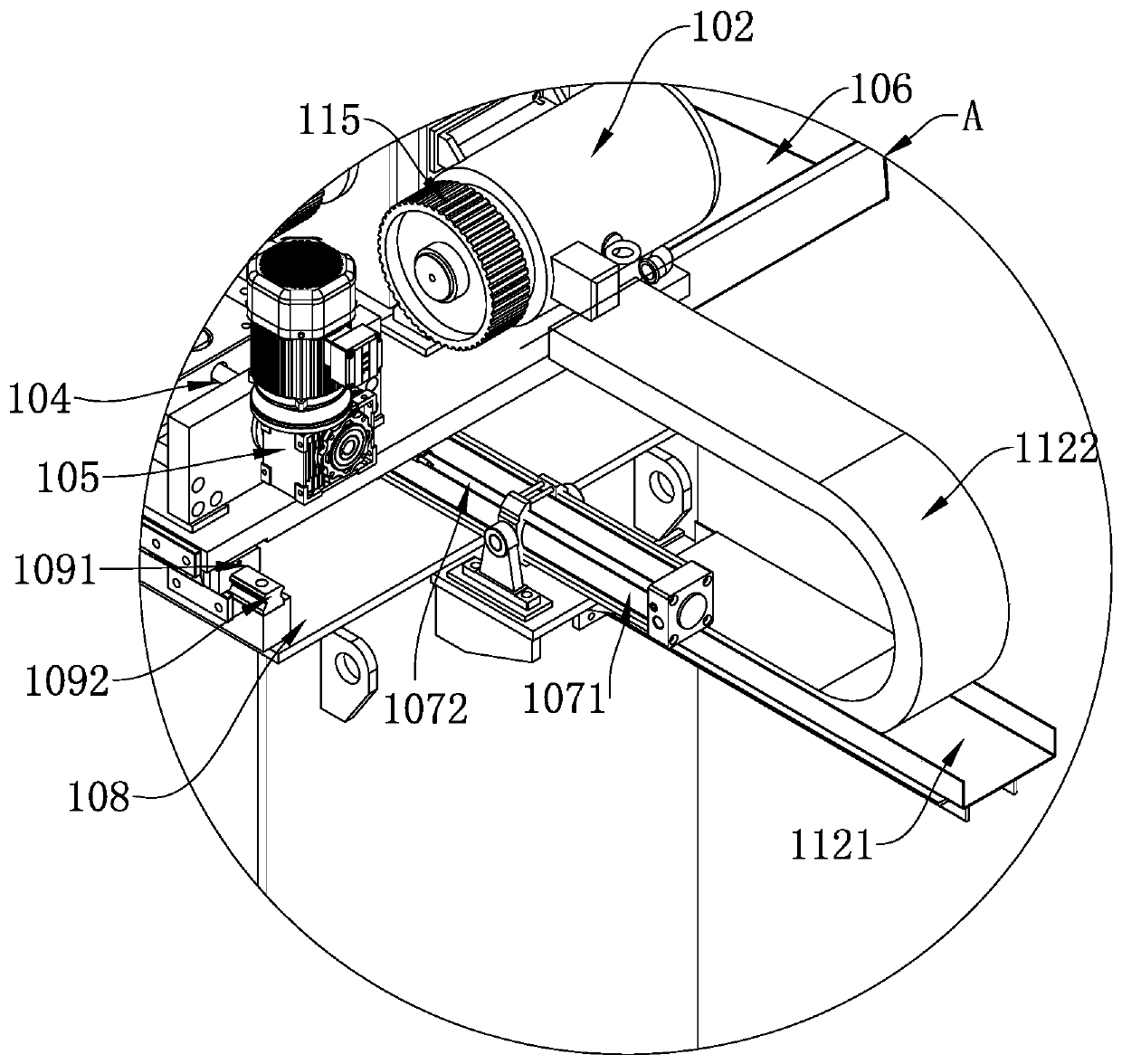

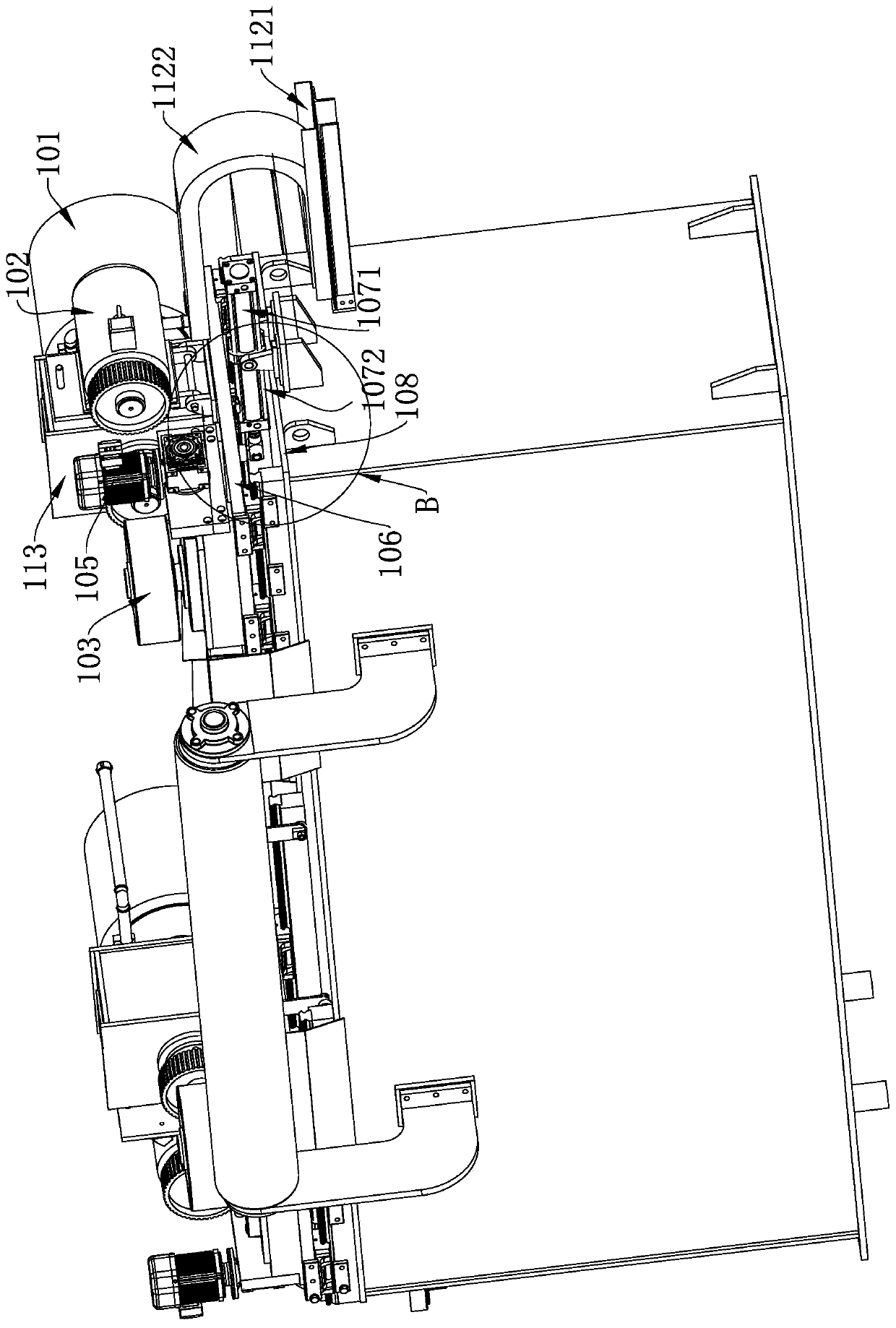

[0063] A steel plate side derusting device, such as Figure 1~8 shown, including,

[0064] Opposite to the steel plate side brush mechanism 100 arranged on the left and right sides of the steel plate, the steel plate side brush mechanism 100 includes:

[0065] The frame 108 is configured as the supporting body of the steel plate side brush mechanism 100;

[0066] The storage platform 106 is arranged on the frame 108, and the storage platform 106 is relatively moved with the frame 108 under the action of the storage platform translation mechanism. Specifically, the storage platform translation mechanism is a cylinder structure 107, including The connected cylinder base 1071, the cylinder push rod 1072 connected with the storage table 106;

[0067] Scale-breaking roller 101, which is installed on the storage table 106, and is configured to brush the side of the steel plate by rotation, the scale-breaking roller 101 and the storage table 106 are synchronously translated, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com