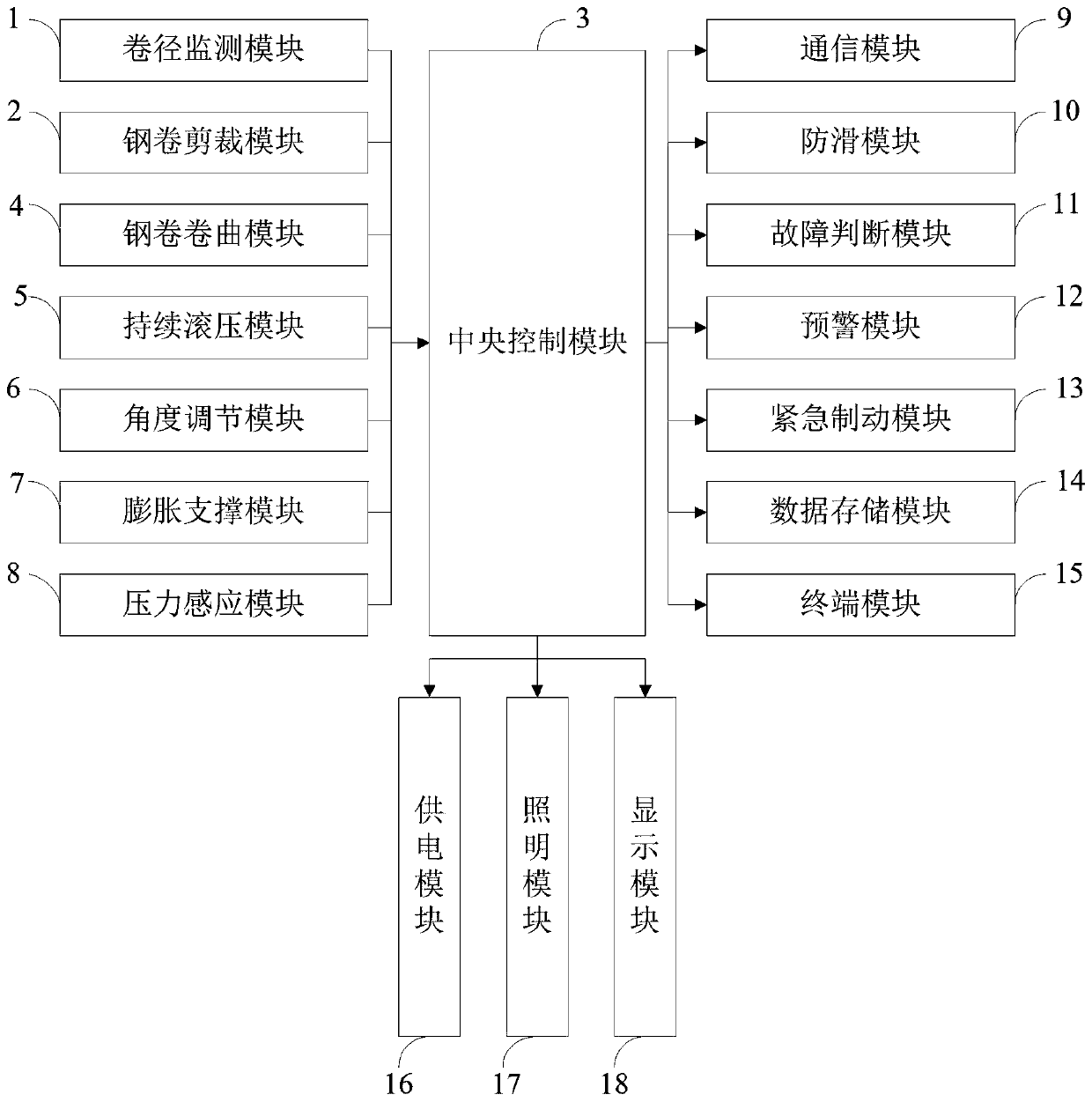

Steel coil longitudinal shear printing management system and method based on big data

A print management and big data technology, applied in other manufacturing equipment/tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the impact on product polishing, electroplating and other processes, economic losses, and easy to produce folds on the surface of strip steel And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

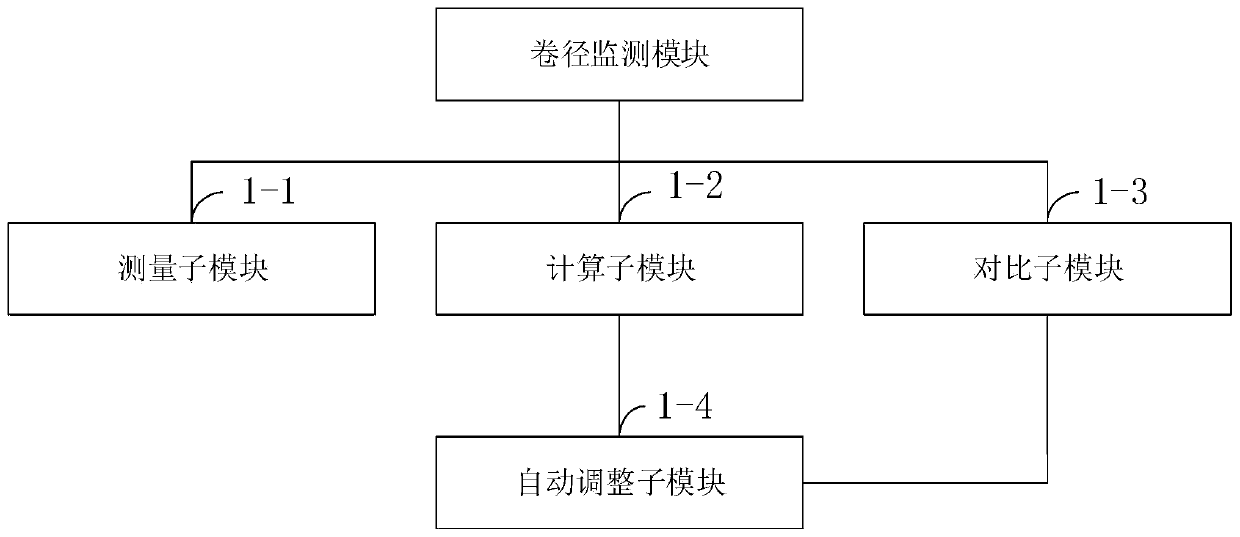

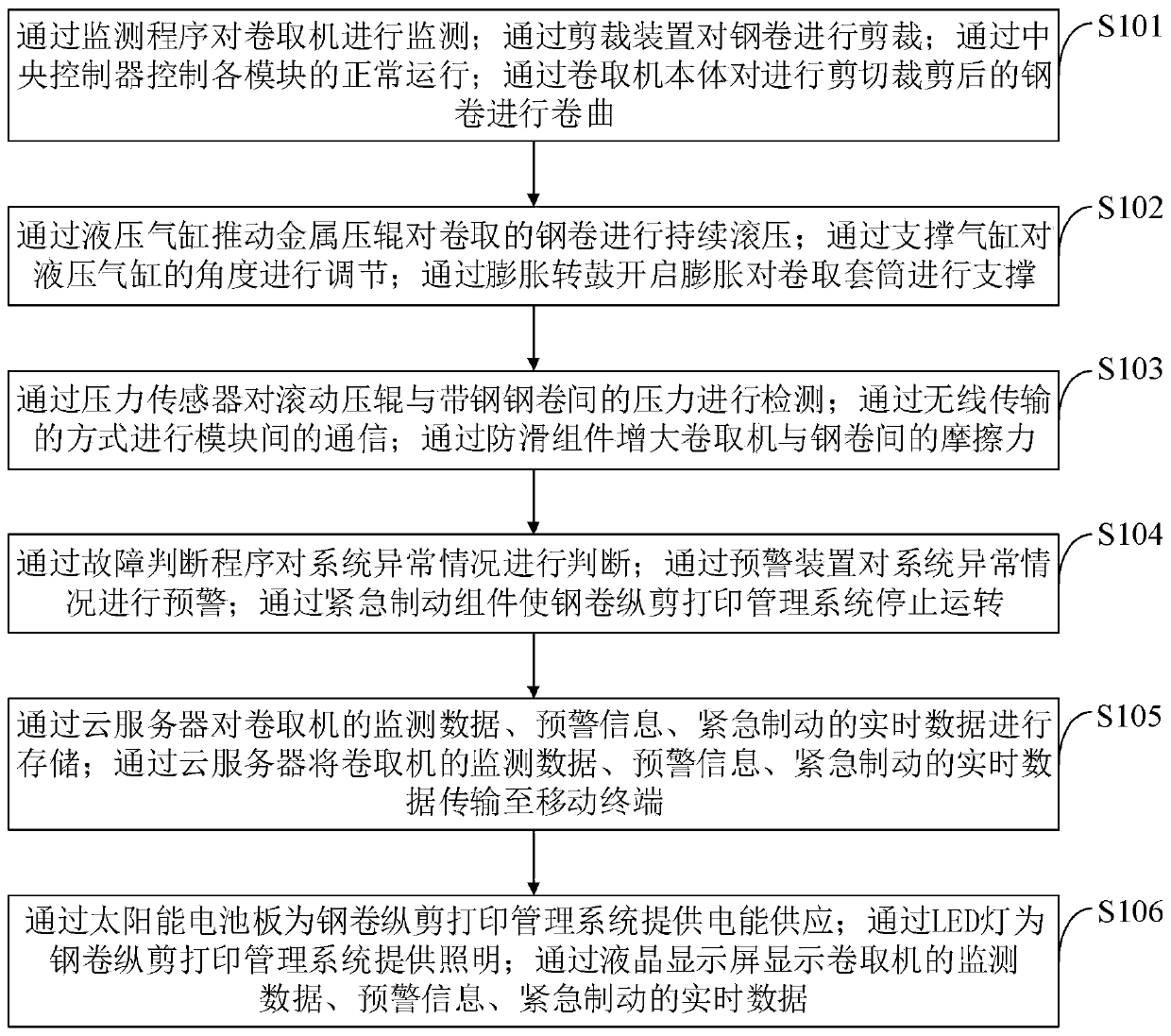

[0110] The big data-based steel coil slitting and printing management method provided by the embodiment of the present invention includes image 3 Included content, the difference is that the roll diameter calculation method further includes:

[0111] Rolling diameter calculation method 1:

[0112] Rolling diameter calculation method two:

[0113] Among them, L is the coiled length, H is the thickness of the steel coil, r is the inner diameter of the coil, v is the line speed of the unit, i is the speed ratio, and n is the rotational speed.

Embodiment 2

[0115] The big data-based steel coil slitting and printing management method provided by the embodiment of the present invention includes image 3 The content included, the difference is that the abnormal conditions in the judgment of system abnormal conditions through the fault judgment program include:

[0116] (1) Turn on the auxiliary winding roller of the coiler, so that the drum of the coiler rotates at a speed of 2m / s. Normally, a continuous buzzing sound below 30 decibels should be heard. If you can hear three periodic clicking, clicking, and clicking sounds greater than 90 decibels every time the reel rotates, it can be preliminarily determined that the accuracy of the reel of the coiler is abnormal.

[0117] (2) Observing on the man-machine interface monitoring screen of the coiler operation table, if the pressure of the coiler auxiliary roller of the coiler reaches more than 30KN during zero adjustment, and at the same time, the coiler auxiliary roller of the zero a...

Embodiment 3

[0120] The big data-based steel coil slitting and printing management method provided by the embodiment of the present invention includes image 3 The content included, the difference is that the abnormal situation in the judgment of the abnormal situation of the system through the fault judgment program further includes:

[0121] (1) During the zero-adjustment process, listen to the sound of the contact between the coiler auxiliary roller and the reel on the spot, and observe the zero-adjustment on the man-machine interface monitoring screen of the coiler operation desk. Two to three sounds, it can be considered that the zero adjustment is abnormal, and it can be further judged that the coil accuracy of the coiler is abnormal.

[0122] (2) After the zero adjustment is completed, the auxiliary roll of the coiler is opened quickly, and the reel runs at a speed of 2M / S. Adjust the roll gap of the auxiliary roll of the programmable automation controller to -1mm. If the sound bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com