Machine room inspection method based on image processing technology

An image processing and machine room technology, applied in image communication, recording/indicating event time, instruments, etc., can solve the problems of locating faulty equipment, insufficient inspection accuracy and timeliness, and high labor costs, and achieve enhanced production safety, It is convenient to analyze the cause of failure and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

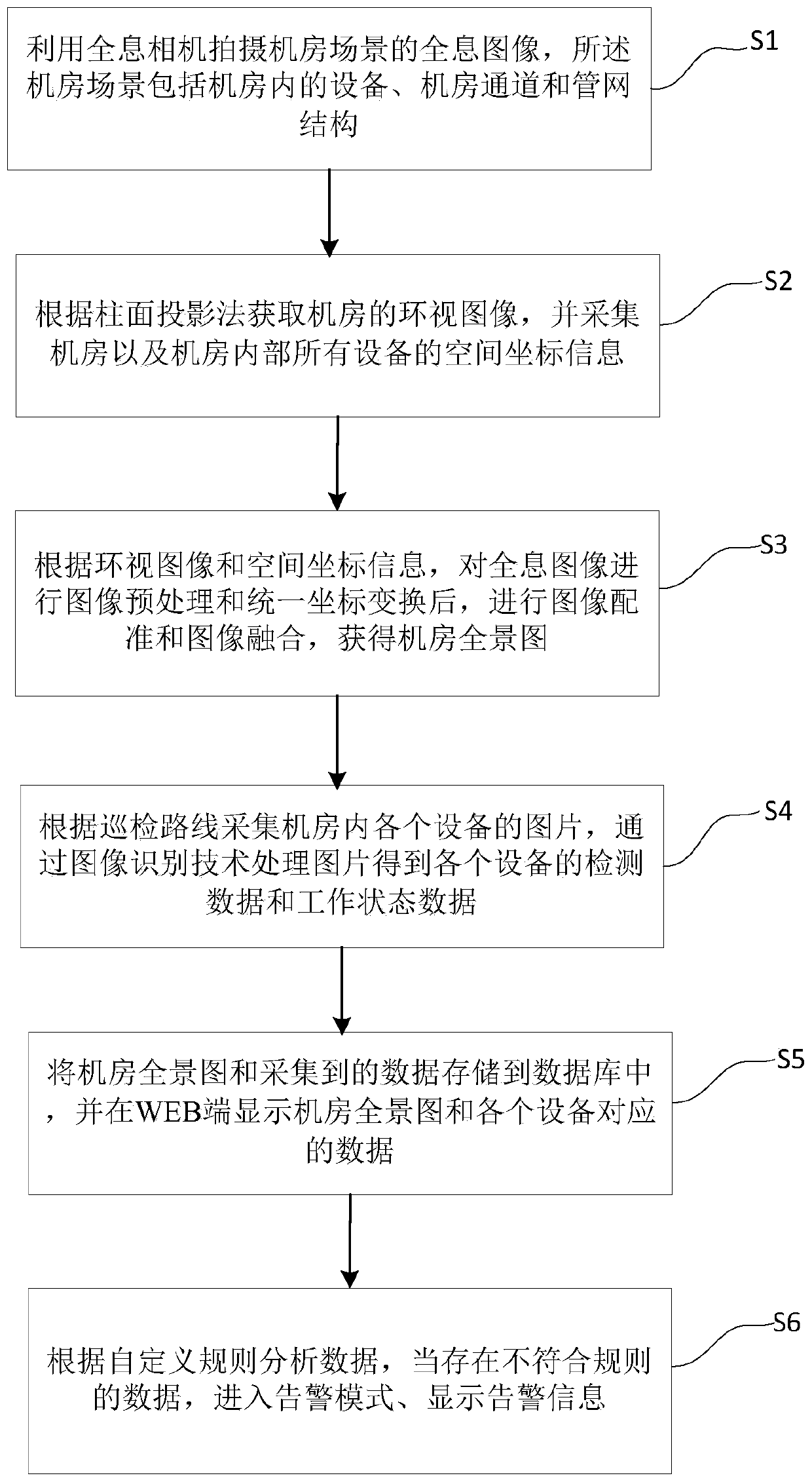

[0033] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0034] The present invention proposes a computer room inspection method based on image processing technology, combined with the field situation of the power system information communication management computer room, using three-dimensional scanning, three-dimensional reconstruction and other technologies, to realize the space-based inspection of equipment, channels, pipe networks, etc. The 3D virtual computer room of the coordinate information is accurately constructed. The computer room operation and maintenance personnel can browse the computer room environment, equipment and line structure through the virtual computer room, simulate the inspection route and key equipment inspection in the real environment, and centrally manage the real-time operation status and operation data of the complex detection equipment and software systems in the computer room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com