Tunable plasma photonic crystal fiber device

A technology of photonic crystal fiber and plasma, which is applied in the field of plasma technology and photonic crystal, can solve the problems of photonic crystal fiber photonic bandgap characteristics difference, affect the infrared light transmission tuning effect, and the plasma filling is not easy to be uniform, so as to avoid Effects of laser scattering or deflection, breakdown voltage reduction, and ease of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

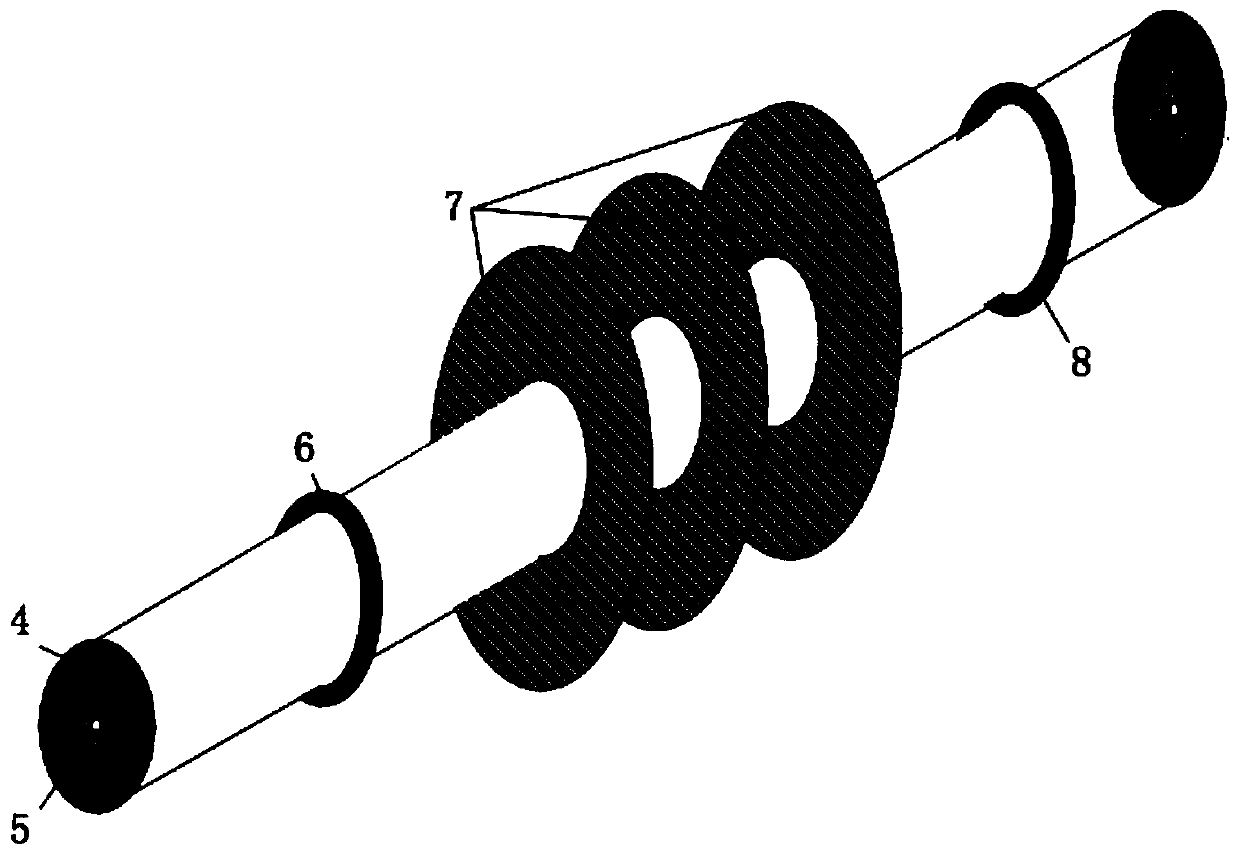

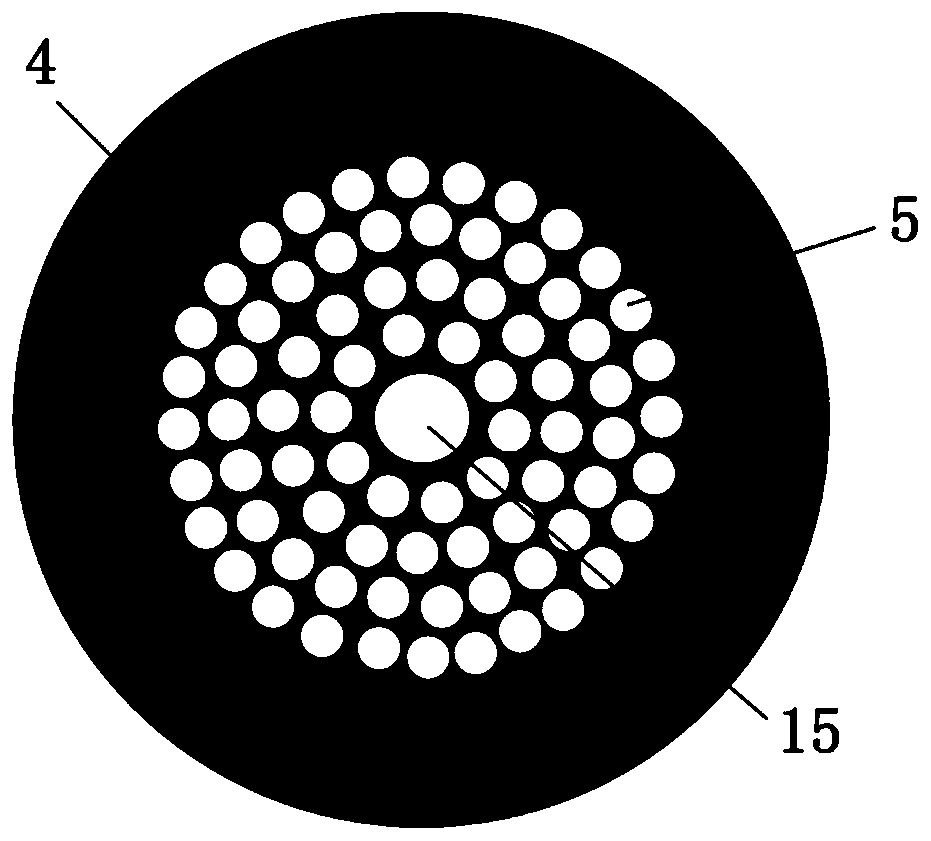

[0031] Such as figure 1 As shown, a tunable plasma photonic crystal fiber device proposed by the present invention includes an incident Brewster window 2, an inert working gas 3, a photonic crystal fiber (containing quartz 4, a hollow hole array 5 and a fiber core 15), a high voltage electrode 6. Insulation sheet 7, ground electrode 8, outgoing Brewster window 9, protection resistor 13, and high-voltage pulse power supply 14. In order to cooperate with the implementation of the device, an infrared laser 1 , a beam splitter 10 , a polarization measuring instrument 11 and a photomultiplier tube 12 are also provided. Such as figure 2 As shown, the photonic crystal fiber is of quartz-hollow hole bandgap type, and hollow hole arrays 5 are periodically arranged in the fiber, the hollow holes run through both ends of the fiber, and the holes ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com