Core-shell structure precursor for lithium ion layered positive electrode material and preparation method of core-shell structure precursor

A core-shell structure and positive electrode material technology, applied in structural parts, chemical instruments and methods, battery electrodes, etc., can solve the problem of low fault tolerance rate, achieve the effect of simple parameters, controllable production capacity, and prevent cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

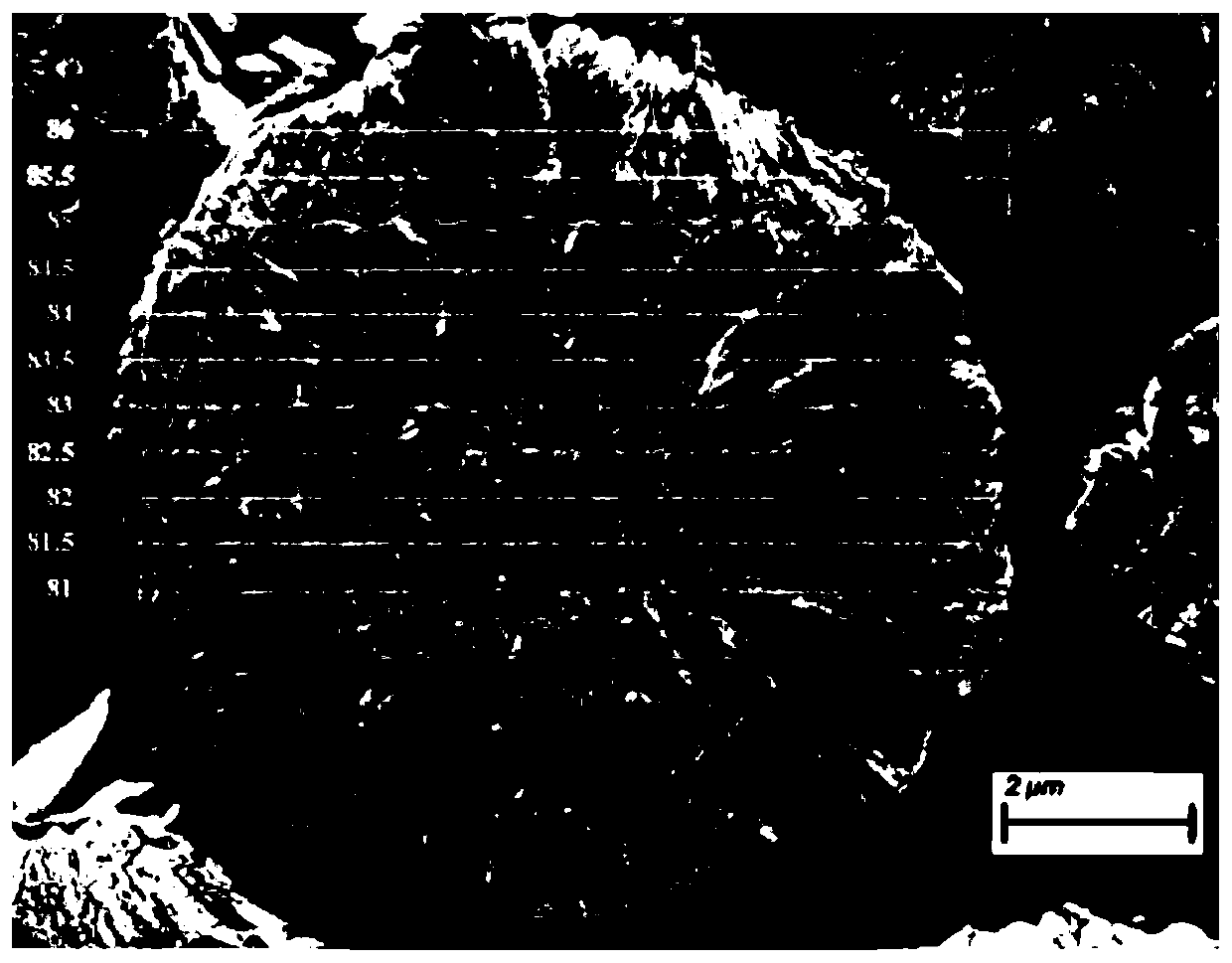

Image

Examples

Embodiment 1

[0028] A preparation method of a core-shell structure precursor for a lithium-ion layered positive electrode material, specifically comprising the following steps:

[0029] (1), press Ni 0.85 co 0.1 mn 0.05 SO 4 The molar ratio configuration metal sulfate mixed solution, then the metal sulfate mixed solution (the metal ion concentration is 2mol / L, and the feeding flow rate is 30mL / min), lye (4.5mol / L) and ammonia complexing agent solution ( 9mol / L) in the reaction kettle, and reacted for 0.5h under the conditions of controlling the ammonia concentration in the reaction solution to 10g / L and the pH to 12.5, to obtain the initial precursor seed material;

[0030] (2) Increase the amount of ammonia complexing agent added to adjust the ammonia concentration of the reaction solution in the reactor to 12g / L, reduce the amount of lye added to adjust the pH to 11.5, and continue the reaction until the precursor seed grows to 93% of the target particle size %, to obtain the core la...

Embodiment 2

[0036] A preparation method of a core-shell structure precursor for a lithium-ion layered positive electrode material, specifically comprising the following steps:

[0037] (1), press Ni 0.83 co 0.10 mn 0.05 Ti 0.02 SO 4 The molar ratio of the metal sulfate mixed solution is configured, and then the metal sulfate mixed solution (the metal ion concentration is 1.6mol / L, and the feeding flow rate is 20mL / min), sodium hydroxide solution (4.2mol / L) and ammonia complexation The reagent solution (7mol / L) was placed in the reaction kettle, and the ammonia concentration in the reaction solution was controlled to be 8.5g / L and the pH was 12.2 to react for 1h to obtain the initial precursor seed material;

[0038] (2) Increase the amount of ammonia complexing agent added to adjust the ammonia concentration of the reaction solution in the reactor to 10.5g / L, reduce the amount of lye added to adjust the pH to 11.3, and continue the reaction until the precursor seed material grows to t...

Embodiment 3

[0043] A preparation method of a core-shell structure precursor for a lithium-ion layered positive electrode material, specifically comprising the following steps:

[0044] (1), press Ni 0.88 co 0.05 mn 0.05 Zr 0.02 SO 4 The molar ratio of the metal sulfate mixed solution is configured, and then the metal sulfate mixed solution (the metal ion concentration is 2.2mol / L, and the feeding flow rate is 20mL / min), sodium hydroxide solution (5mol / L) and ammonia complexing agent solution (11mol / L) was placed in the reaction kettle, and the ammonia concentration in the reaction liquid was controlled to be 11g / L, and the pH was 12.7 to react for 1.5h to obtain the initial precursor seed material;

[0045] (2) Increase the amount of ammonia complexing agent to adjust the ammonia concentration of the reaction solution in the reactor to 13g / L, reduce the amount of lye to adjust the pH to 11.6, and continue the reaction until the precursor seed material grows to 90% of the target partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com