A Centrifugal Air Classifier for Ultrafine Powder

An air classifier and ultra-fine powder technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problem of lowering the lower limit of classification, large secondary flow energy loss, and high speed Large gradient and other problems, to achieve the effect of reducing size and strength, reducing turbulence intensity, and lowering the lower limit of classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

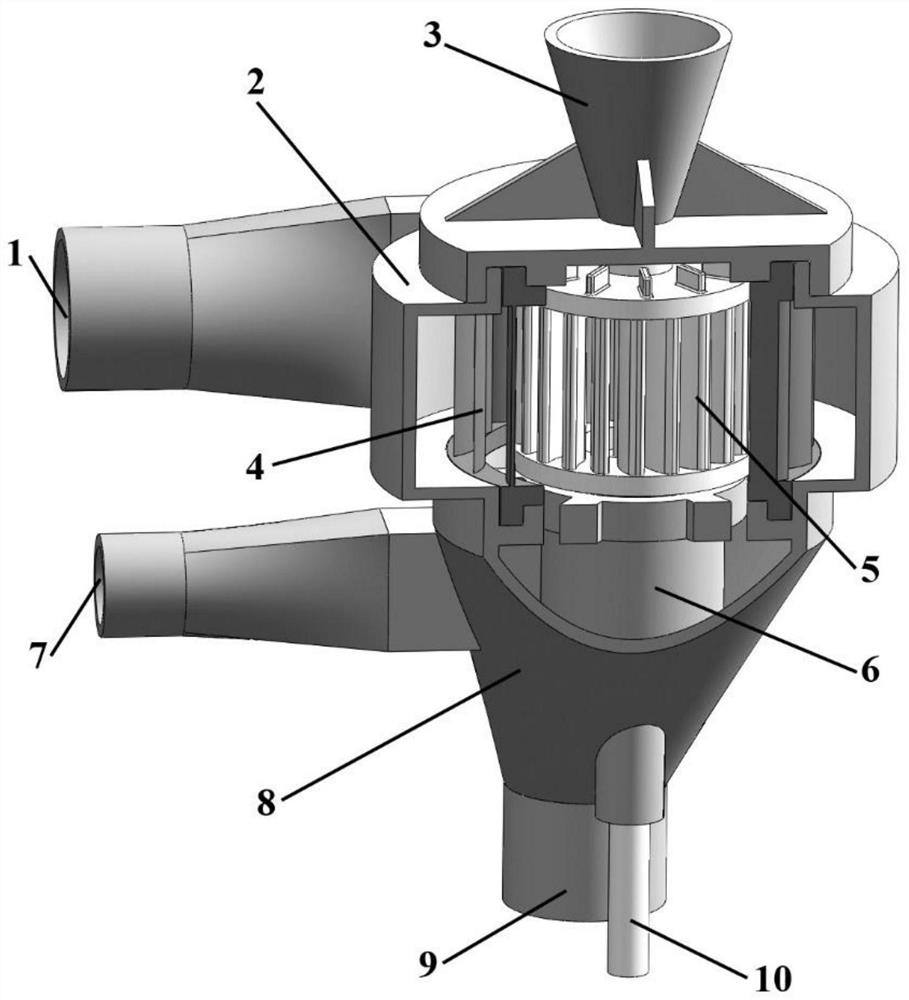

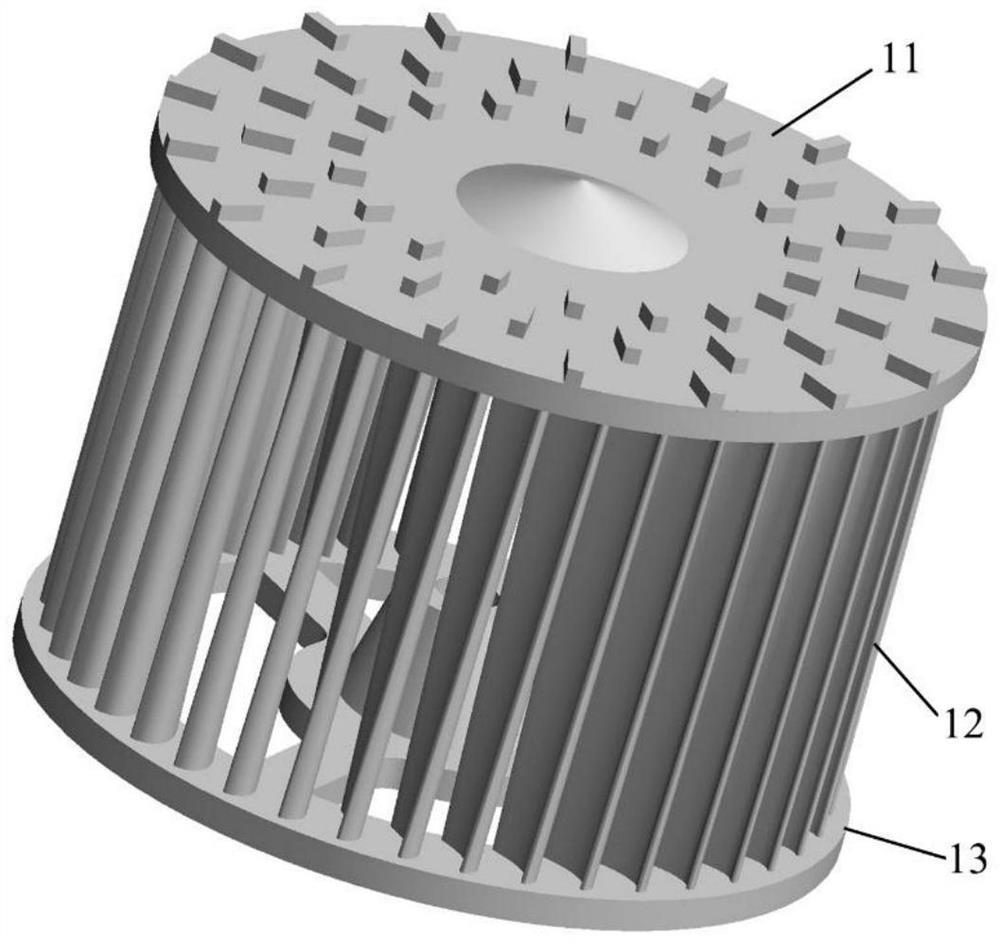

[0021] Such as figure 1 As shown, a kind of centrifugal air classifier for superfine powder of the present invention comprises air inlet duct 1, classifying chamber 2, top cover 3, wind guide vane grid 4, classifying impeller 5, fine powder transfer chamber 6, Conical housing 8, coarse powder discharge port 9, air outlet pipe 7. The plurality of air inlet pipes 1 are arranged in a circular equidistant manner with the geometric central axis of the classification chamber 2 as the axis, and are connected to the classification chamber 2 along the tangential direction; the top cover 3 is located above the classification chamber 2, including the feeding Funnel, the feeding funnel communicates with the air-closed feeding device; the wind guide vane grid 4 is fixed in the classification chamber 2 through an annular slot, and the classification impeller 5 is located at the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com