Less-maintenance valve-controlled alkaline secondary battery

A secondary battery, valve-controlled technology, applied in the direction of alkaline storage battery, alkaline storage battery manufacturing, climate sustainability, etc., can solve problems such as battery pressure increase, short-circuit conductivity, electrolyte drying, etc., to prevent drying up , The effect of overcoming the deformation of expansion and powder removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

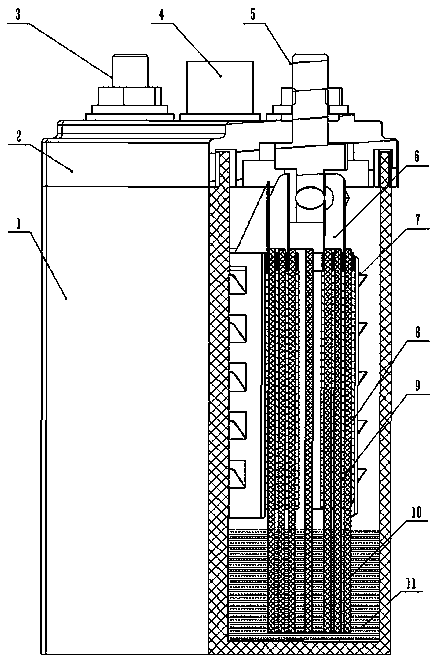

[0009] The technical solution of the present invention is described in detail in conjunction with the accompanying drawings, a low-maintenance valve-regulated alkaline secondary battery, including a battery case 1 containing an electrolyte and a pole plate group arranged in the battery case 1, the battery case 1 Adopt a single chamber or a conjoined square structure that is isolated into multiple single chambers. The upper part of the battery case 1 is provided with a battery end cover 2 that is sealed and connected to the battery case. The battery terminal corresponding to the single chamber The cover 2 is provided with an exhaust valve 4, which is used to prevent the deformation and expansion of the battery case 1 caused by the excessive gas pressure during charging; , and between the positive electrode sheet 8 and the negative electrode sheet 9, a diaphragm 10 with an elongated bottom structure is provided, and spring steel sheets 7 with spines are respectively placed on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com