Laser ultrasonic three-dimensional localization and quantitative detection method for multiple defects in material

A quantitative detection method, laser ultrasonic technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of multiple defects, insufficient detection sensitivity and accuracy, etc., to facilitate signal processing and analysis, and overcome the influence of detection sensitivity , Quantitative detection results are accurate and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a laser ultrasonic three-dimensional positioning and quantitative detection method for multiple defects inside the material. The specific implementation scheme is as follows:

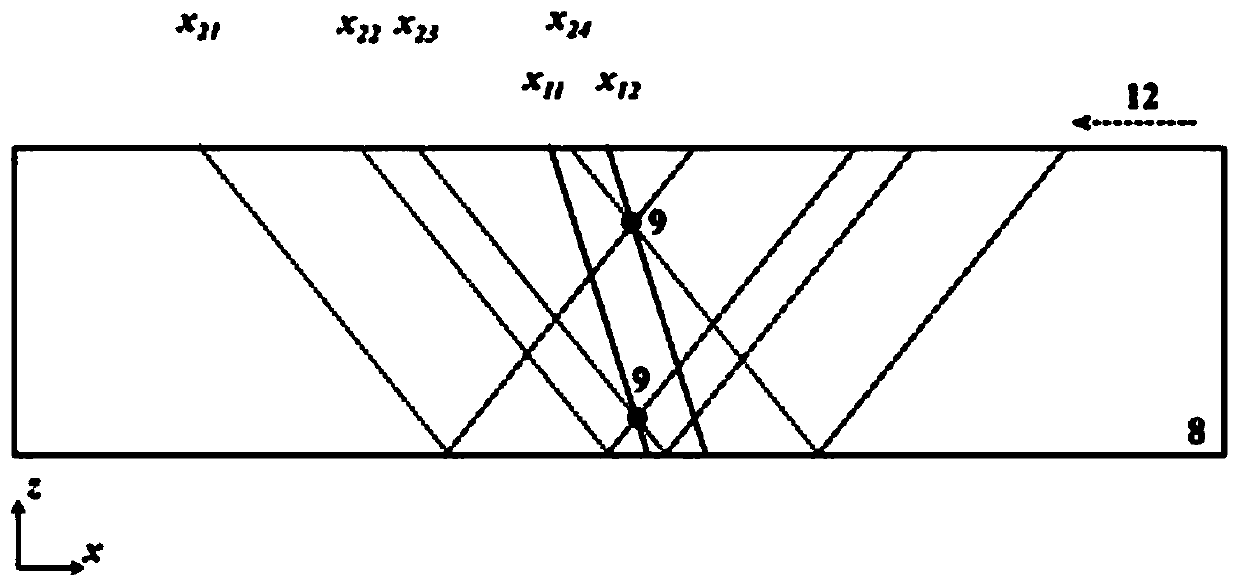

[0049] The size of the aluminum alloy sample is 120mm×80mm×10mm, and there are multiple side through-hole defects drilled inside, with diameters of 0.5mm and 0.8mm respectively. The samples are distributed at different depths at the same horizontal position, such as figure 2 shown.

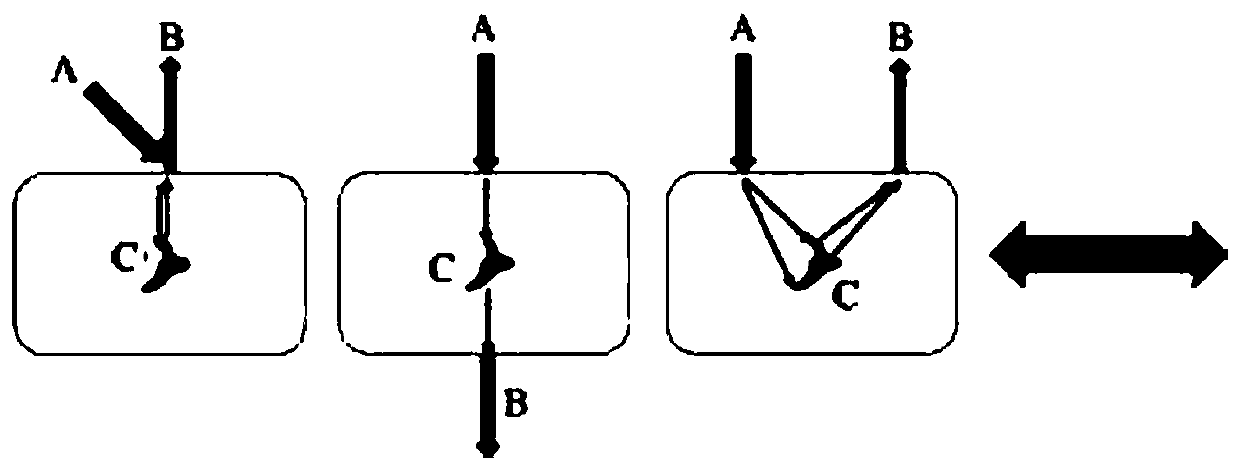

[0050] Nd: YAG laser 1 excites a pulsed laser with a wavelength of 1064nm, a pulse width of 10ns, a repetition rate of 30Hz, and a single pulse energy of 20mJ. After passing through a convex lens 2 (using a cylindrical lens), a linear light source focused at 5mm×0.2mm is irradiated on the aluminum alloy. The ultrasonic body wave excited on the upper surface of the sample 8 is divided into an obliquely transmitted ultrasonic body wave 10 and an incident ultrasonic transverse wave 11 on the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com