Fuel gas distribution device and combustion control method of water heater using same

A distribution device, water heater technology, applied in the direction of combustion method, gas fuel burner, burner, etc., can solve the problems of overheating water temperature, large size of solenoid valve, high cost, etc., achieve stable combustion of gas supply, reduce excess heat, and resist The effect of wind capacity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

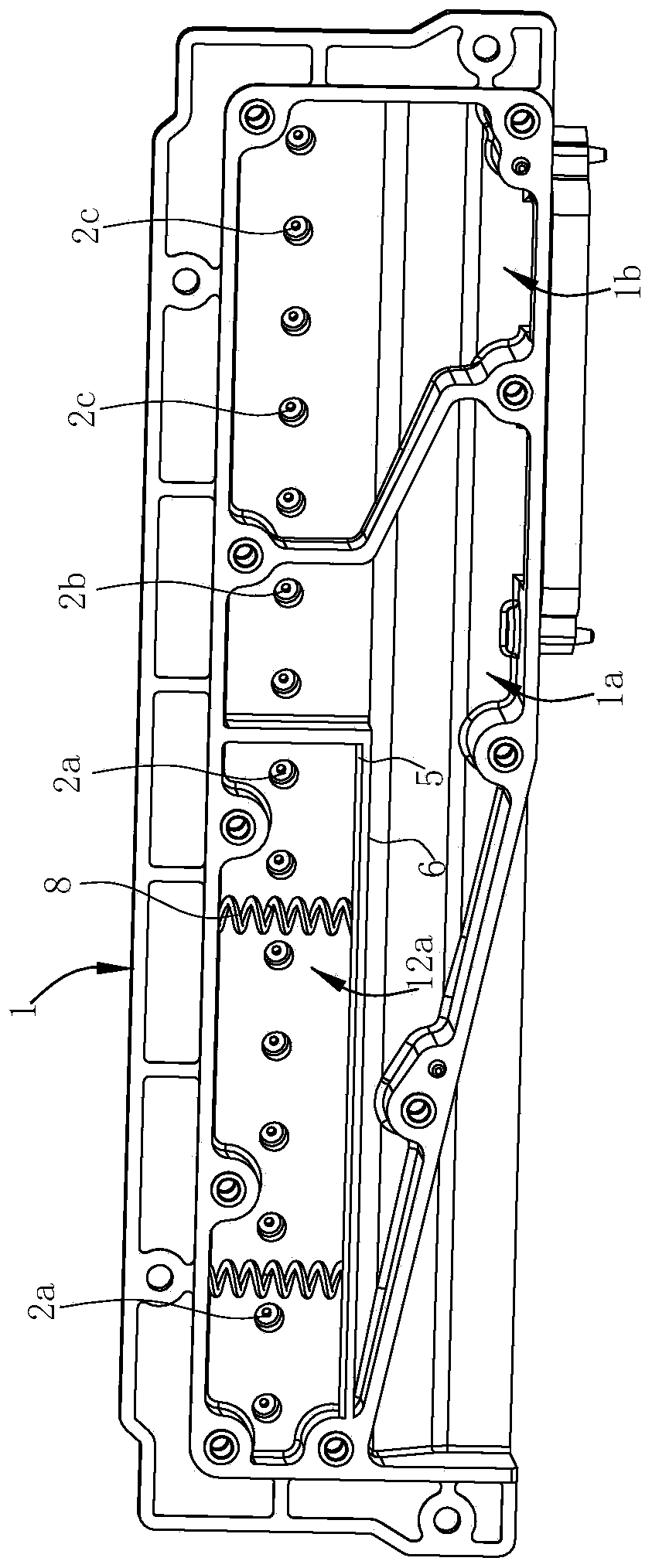

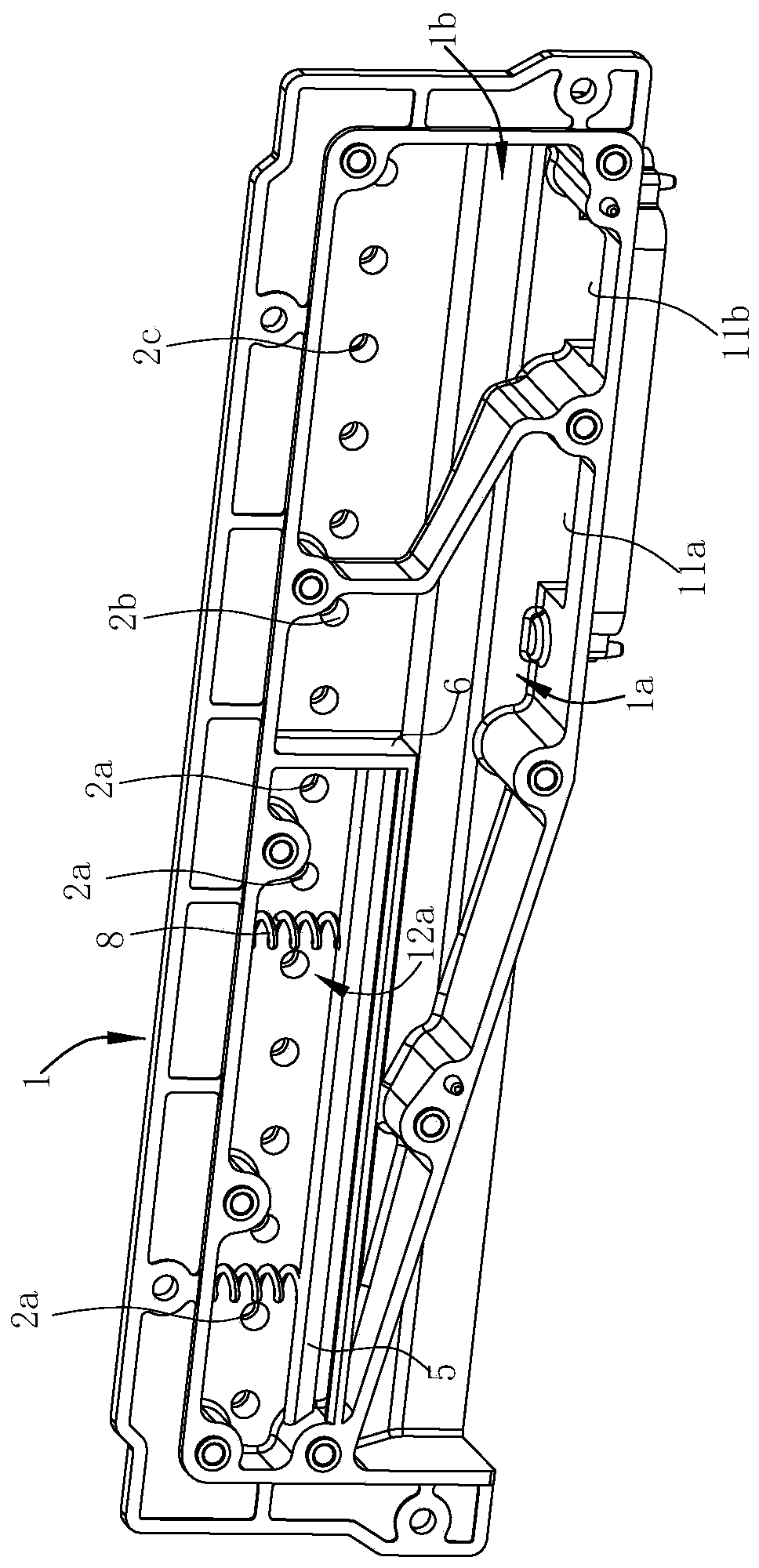

[0042] Such as Figure 1~6 As shown, the gas distribution device in this preferred embodiment includes a housing 1 , a first solenoid valve 3 , a second solenoid valve 4 , an isolation frame 6 and a cover plate 5 . The housing 1 shown in this embodiment does not show the pressure plate, and the pressure plate cooperates with the housing part in the figure to form a cavity.

[0043] The housing 1 has a first distributing chamber 1a and a second distributing chamber 1b that are isolated from each other, and the housing 1 is provided with a first air inlet 11a for gas entering the first distributing chamber 1a and a gas inlet for entering the second distributing chamber. For the second air inlet 11b of 1b, the first solenoid valve 3 is used to control the intake flow of the first air inlet 11a, and the second solenoid valve 4 is used to control the intake flow of the second air inlet 11b.

[0044] The housing 1 is also provided with a first nozzle 2a, a second nozzle 2b and a th...

Embodiment 2

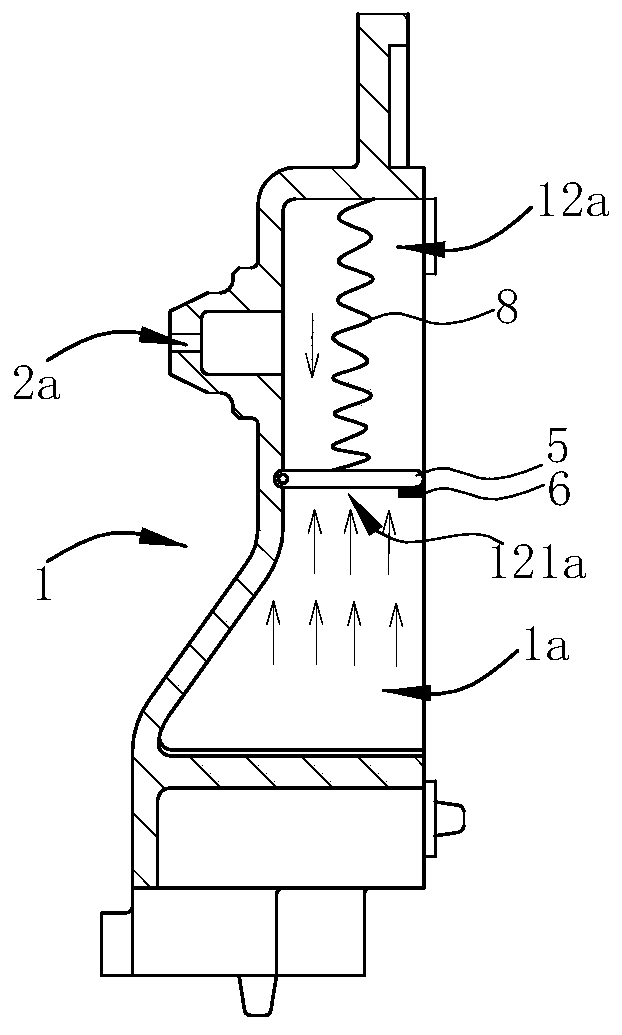

[0059] Such as Figure 7-9 As shown, the difference between Embodiment 2 and Embodiment 1 is that no reset member 8 is provided, and the cover plate 5 resets and closes the through hole 121a only under the action of its own gravity. For other structures, refer to Embodiment 1.

[0060] In addition, the second step in the combustion control method of the water heater is: the main control board changes the current of the first solenoid valve 3 to the fire transmission current I 1 , I 1 I min At this time, the gravity of the cover plate 5 itself is greater than the air intake pressure of the first air inlet 11a, the cover plate 5 closes the through hole 121a, and the first nozzle 2a no longer burns; at the same time, the second solenoid valve 4 is opened, and the second solenoid valve 4 is opened at the same time. Nozzle 2b and the third nozzle 2c (7 nozzles in total) burn, and then perform step 3;

[0061] Step 1 and Step 3 are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com