Closed pressure regulating oil tank capable of realizing high-precision detection of oil quantity

A high-precision, fuel-tank technology, used in fuel supply tank devices, fluid pressure actuation devices, fluid pressure actuation system testing, etc. The problem of heavy cylinder weight, etc., to achieve the effect of high coincidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

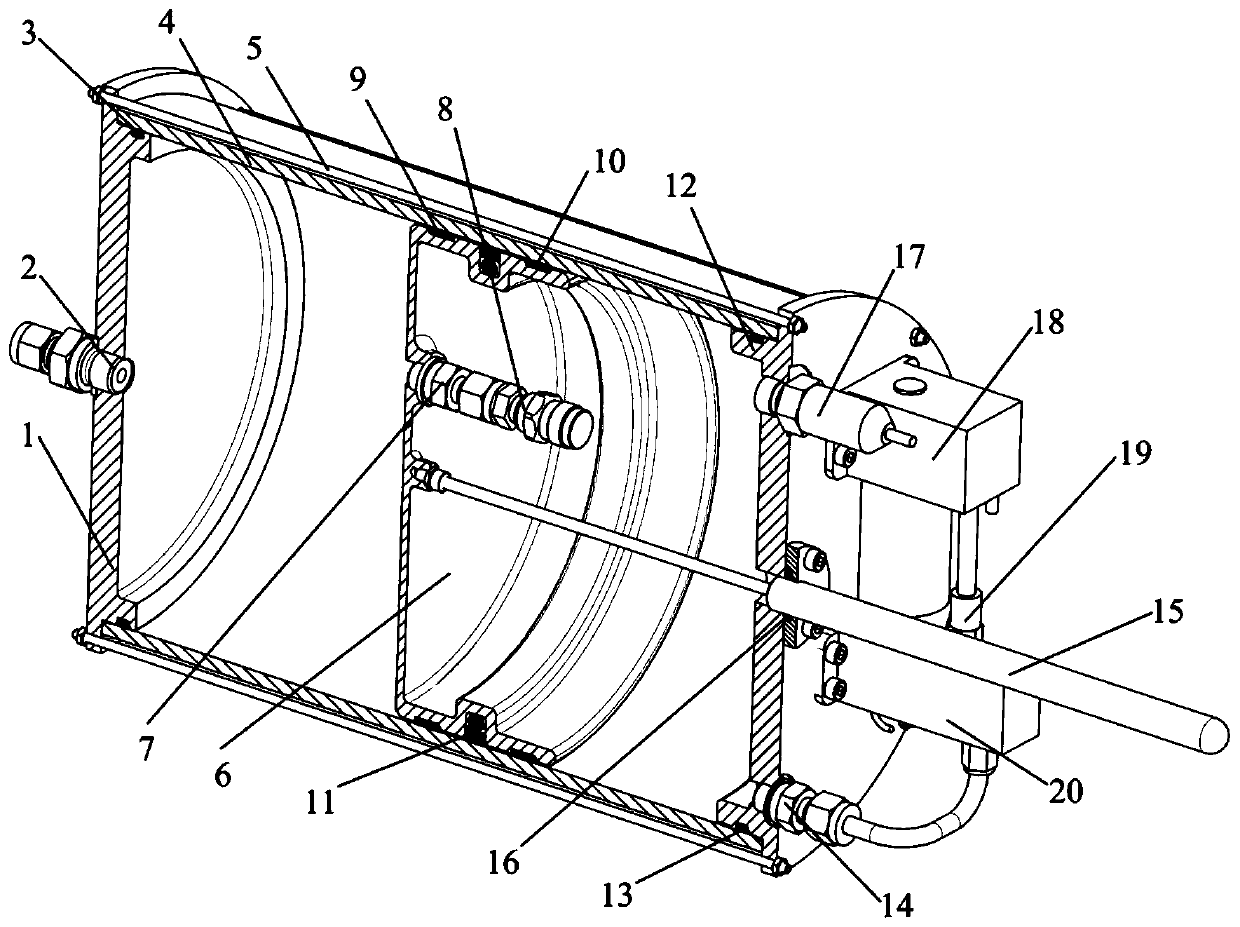

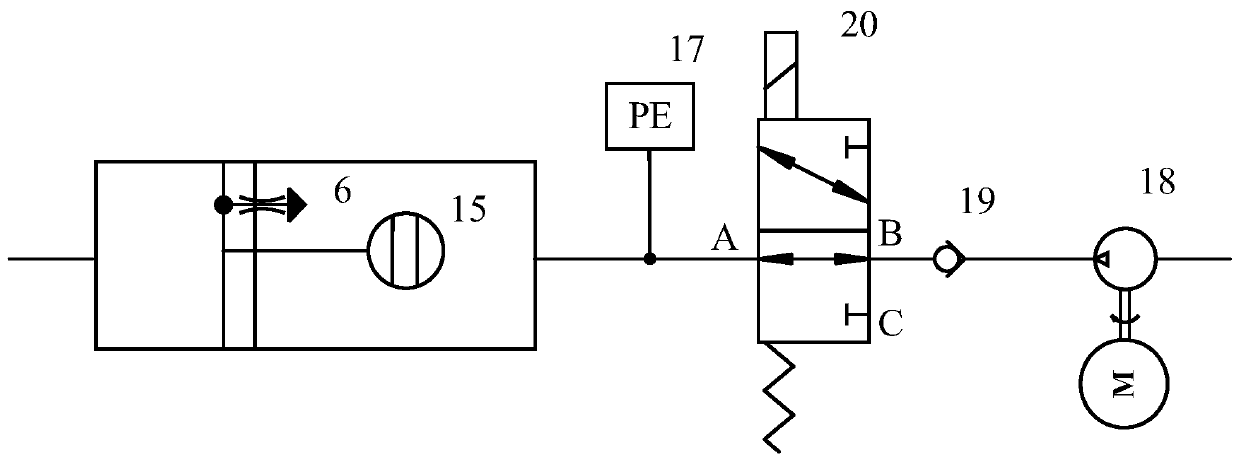

[0029] Such as figure 1 , figure 2 As shown, the present invention proposes a closed pressure-regulating oil tank for high-precision detection of oil quantity. It mainly includes the fuel tank main unit and the air pressure adjustment unit. Such as figure 1shown. The main unit of the oil tank includes: the front end cover of the oil tank 1, the oil inlet and outlet holes of the oil tank 2, the O-ring 3, the wall of the oil tank 4, the tension rod 5, the sealing piston body 6, the exhaust valve hole 7, the exhaust valve 8, First guide ring 9, second guide ring 10, double-acting polyester surface preload seal ring 11, fuel tank rear end cap 12, O-ring 13, fuel tank intake and exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com