Method for preventing hole collapse of drilling pile by automatic ejecting steel protection cylinder

A technology of automatic pop-up and steel casing, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of reduced water head pressure, prone to collapse holes, reduced mud specific gravity, etc. Precise control, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

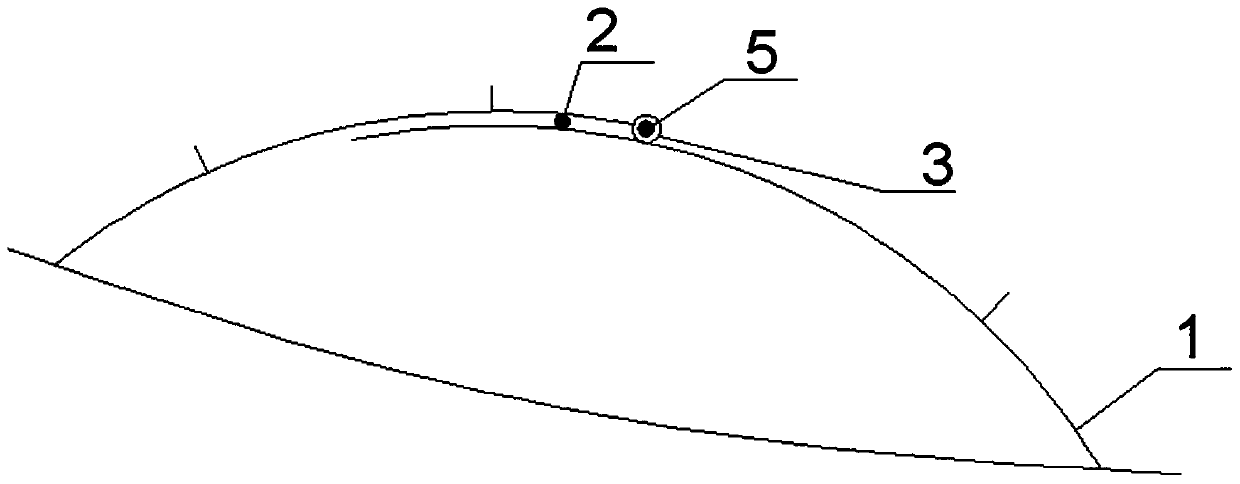

[0028] A method for automatically bouncing steel casings to prevent bored piles from collapsing, which involves lowering the steel casings that can be automatically bouncing after being rolled to the position to be supported in the bored piles, and then bouncing the steel casings , the outer wall of the steel casing is attached to the hole wall of the bored pile and fixed to form a support.

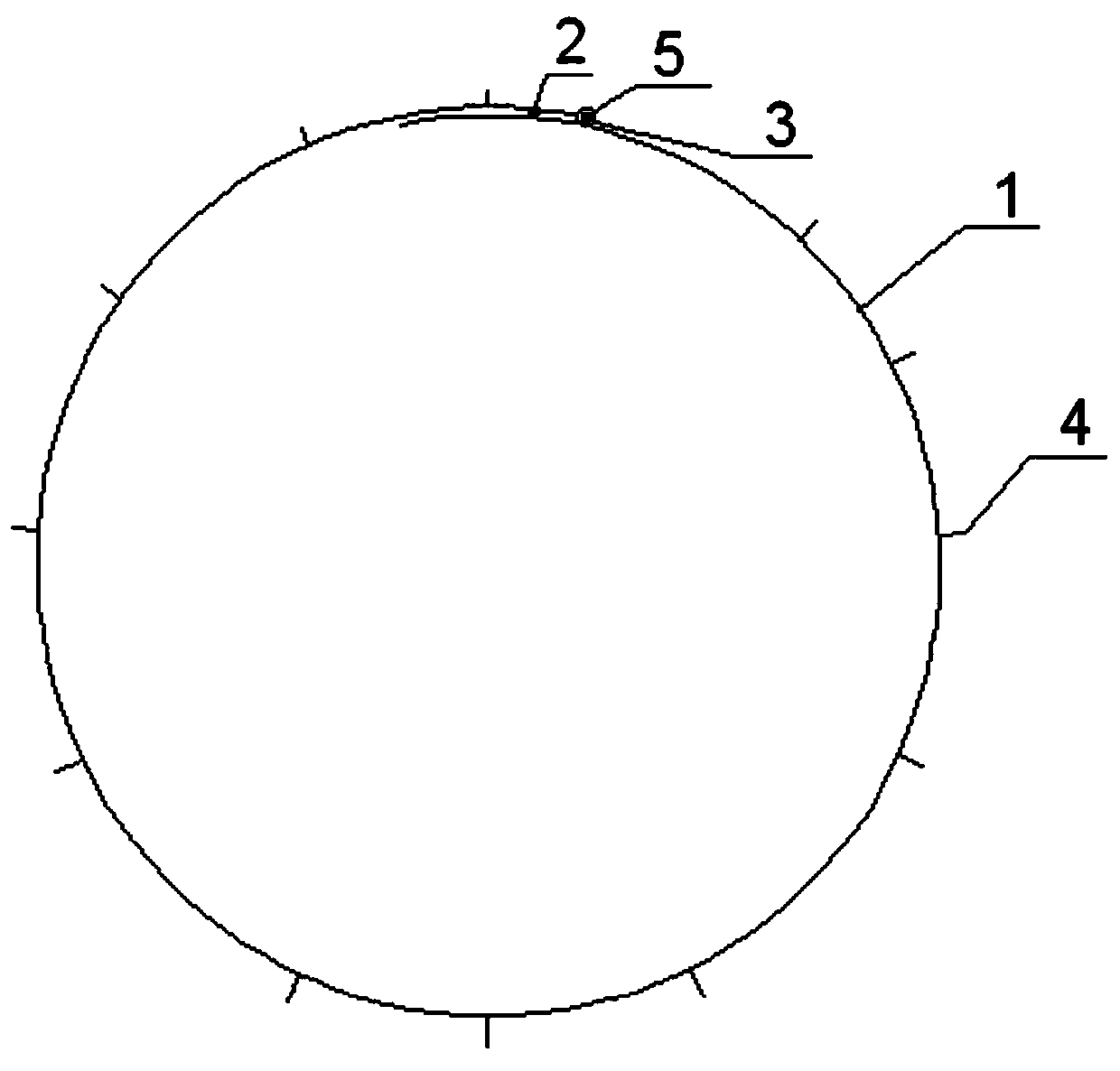

[0029]As shown in the accompanying drawings, the device for preventing bored piles from collapsing in order to realize the above method is as follows: it includes a steel casing device that can automatically bounce, and a steel casing hanging device. The steel casing device that can be automatically bounced off includes a cylindrical steel casing 1 made of rolled steel sheets. A steel bar with a diameter of 6 mm is welded along the height direction of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com