Preparation method of iron glucoheptonate

A technology of glucoheptonate and gluconic acid, which is applied in the field of preparation of iron glucoheptonate, can solve the problems of inability to directly obtain high-purity iron glucoheptonate and difficult separation, and achieve simple and environmentally friendly preparation process and high reactivity , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

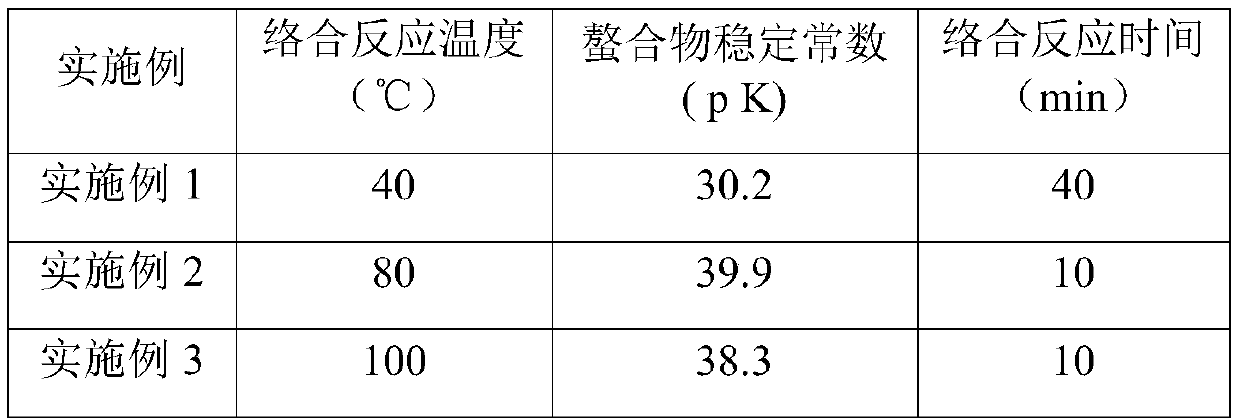

Examples

Embodiment 1

[0026] (1) Preparation of gluconic acid aqueous solution:

[0027] Solid sodium glucoheptonate (for example, Wuhan Yuancheng Science and Technology Development Co., Ltd. industrial grade) is formulated into an aqueous solution with a mass percentage of 98%, and then passed through an activated large-pore strong acid cation exchange resin (for example, Shanghai Jinkai Resin Co., Ltd. Company D301) for ion exchange, after sufficient ion exchange, an aqueous solution of glucoheptononic acid with a mass percentage of about 30% is obtained.

[0028] (2) Preparation of ferric hydroxide:

[0029] React 320g of 10% ferrous sulfate aqueous solution with 100g of concentrated ammonia water to form a precipitate, let it stand for stratification, filter the reaction solution, wash the filter cake with deionized water for 2-3 times, blow in air to completely oxidize the filter cake It is reddish-brown powder, which is ferric hydroxide powder.

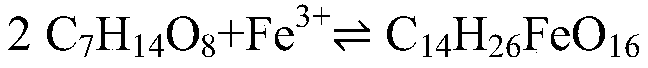

[0030] (3) Preparation of Iron Glucoheptonat...

Embodiment 2

[0033] (1) Preparation of gluconic acid aqueous solution:

[0034] Solid sodium glucoheptonate (for example, Wuhan Yuancheng Science and Technology Development Co., Ltd. industrial grade) is formulated into an aqueous solution with a mass percentage of 98%, and then passed through an activated large-pore strong acid cation exchange resin (for example, Shanghai Jinkai Resin Co., Ltd. Company D301) for ion exchange, after sufficient ion exchange, an aqueous solution of glucoheptononic acid with a mass percentage of about 30% is obtained.

[0035] (2) Preparation of ferric hydroxide:

[0036] React 320g of 10% ferrous sulfate aqueous solution with 100g of concentrated ammonia water to form a precipitate, let it stand for stratification, filter the reaction solution, wash the filter cake with deionized water for 2-3 times, blow in air to completely oxidize the filter cake to Reddish-brown powder is ferric hydroxide powder.

[0037] (3) Preparation of Iron Glucoheptonate

[0038...

Embodiment 3

[0040] (1) Preparation of gluconic acid aqueous solution:

[0041] Solid sodium glucoheptonate (for example, Wuhan Yuancheng Science and Technology Development Co., Ltd. industrial grade) is formulated into an aqueous solution with a mass percentage of 98%, and then passed through an activated large-pore strong acid cation exchange resin (for example, Shanghai Jinkai Resin Co., Ltd. Company D301) for ion exchange, after sufficient ion exchange, an aqueous solution of glucoheptononic acid with a mass percentage of about 30% is obtained.

[0042] (2) Preparation of ferric hydroxide:

[0043] React 320g of 10% ferrous sulfate aqueous solution with 100g of concentrated ammonia water to form a precipitate, let it stand for stratification, filter the reaction solution, wash the filter cake with deionized water for 2-3 times, blow in air to completely oxidize the filter cake It is reddish-brown powder, which is ferric hydroxide powder.

[0044] (3) Preparation of Iron Glucoheptonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com