Improved residue soil regeneration backfill material and preparation method thereof

An improved, muck-based technology, applied in the field of civil engineering materials, can solve problems such as huge traffic pressure, construction waste polluting the environment, and affecting construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Correspondingly, the embodiment of the present application also provides a preparation method of the above-mentioned improved muck reclaimed backfill material, including the following steps:

[0052] S1. Pre-treatment: pre-treat the muck to remove foreign matter and polluted and deteriorated parts;

[0053] S2. Proportioning design: Weigh each component according to the formula of the improved muck reclaimed backfill material described above;

[0054] S3. Desilting treatment: mixing and stirring the sludge treated with S1 and water to obtain a mixture;

[0055] S4. Mixing operation: Mix the above mixture, cement, fly ash, and early strength agent to obtain the finished product.

[0056] Specifically, in the above step S1, pre-processing the muck includes:

[0057] 1) Remove wood chips, iron chips and other foreign matter mixed in the muck;

[0058] 2) When using polluted and smelly river bottom mud as raw materials, the polluted and deteriorated parts should be removed;

[0059] Spe...

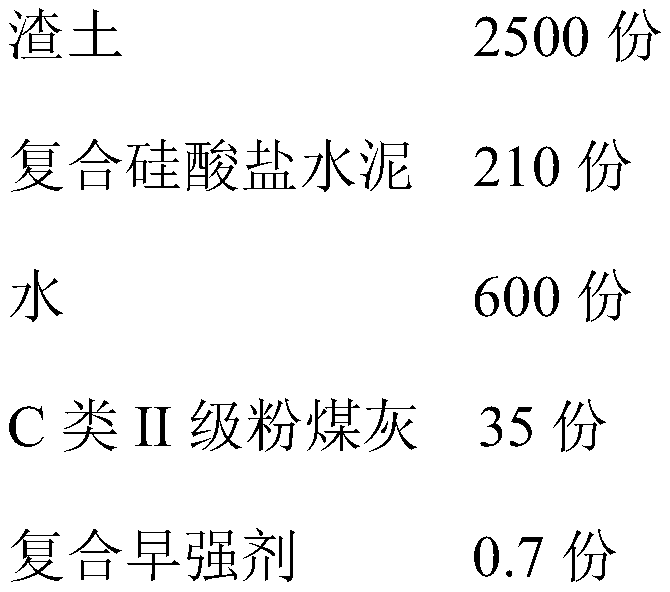

Embodiment 1

[0081] This embodiment provides an improved muck reclaimed backfill material and a preparation method thereof. The above-mentioned improved muck reclaimed backfill material includes the following formula of parts by mass:

[0082]

[0083] The particle size of the above-mentioned muck particles is not greater than 40 mm, wherein the content of particles with a particle diameter of less than 2 mm is 45% by weight, and the content of particles with a particle diameter of 5-20 mm is 25% by weight; the organic matter content in the above-mentioned muck is 3% by weight.

[0084] The preparation method is as follows:

[0085] S11. Pre-treat the muck to remove foreign matter, polluted and deteriorated parts;

[0086] S12. Weigh each component according to the formula of the improved muck reclaimed backfill material described above;

[0087] S13. Mix 2500 parts of S11-treated muck and 600 parts of water to obtain a mixture;

[0088] S14. Mix the above mixture with 210 parts of composite Portlan...

Embodiment 2

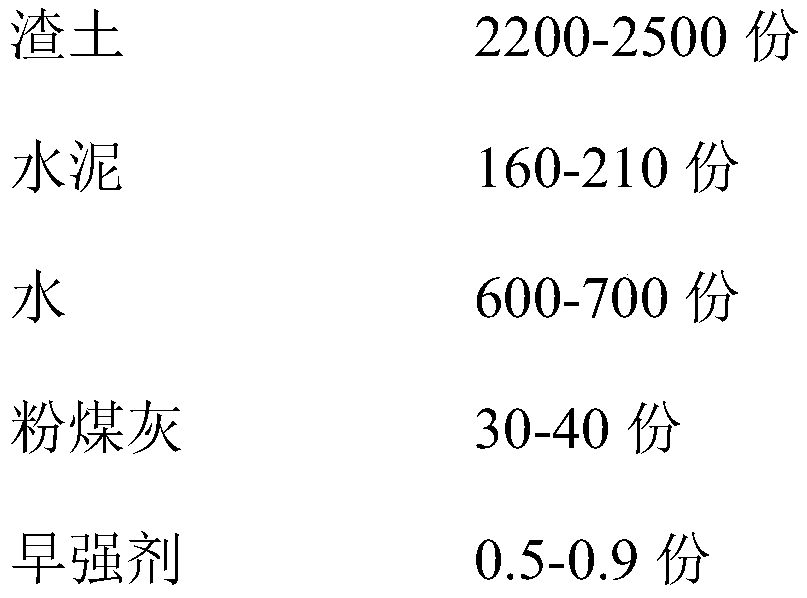

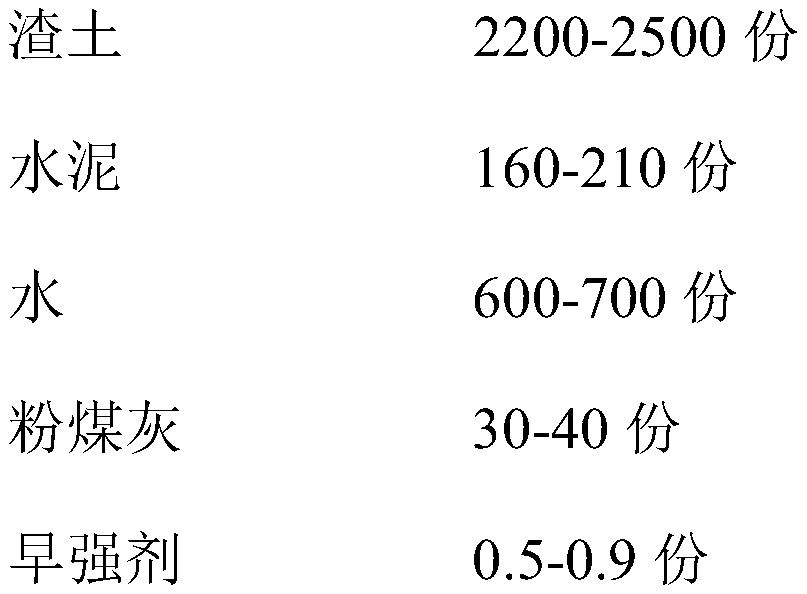

[0096] This embodiment provides an improved muck reclaimed backfill material and a preparation method thereof. The above-mentioned improved muck reclaimed backfill material includes the following formula of parts by mass:

[0097]

[0098] The particle size of the above-mentioned slag particles is not greater than 40 mm, wherein the content of particles with a particle size of less than 2 mm is 45% by weight, and the content of particles with a particle size of 5-20 mm is 25% by weight; the organic matter content in the above-mentioned slag is 3% by weight.

[0099] The preparation method is as follows:

[0100] S21. Pre-treat the muck to remove foreign matter, polluted and deteriorated parts;

[0101] S22. Weigh each component according to the formula of the improved muck reclaimed backfill material described above;

[0102] S23. Mix 2200 parts of the residue treated with S21 and 700 parts of water to obtain a mixture;

[0103] S24. Mix the above mixture with 160 parts of composite Por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com