Method for enhancing production of methanol by using filter screen structure through anaerobic digestion of municipal sludge

An anaerobic digestion and municipal sludge technology, applied in chemical instruments and methods, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of slow hydrolysis rate and low methane production efficiency, and achieve enhanced oxidation The effect of decomposing, increasing gas production and accelerating methane production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

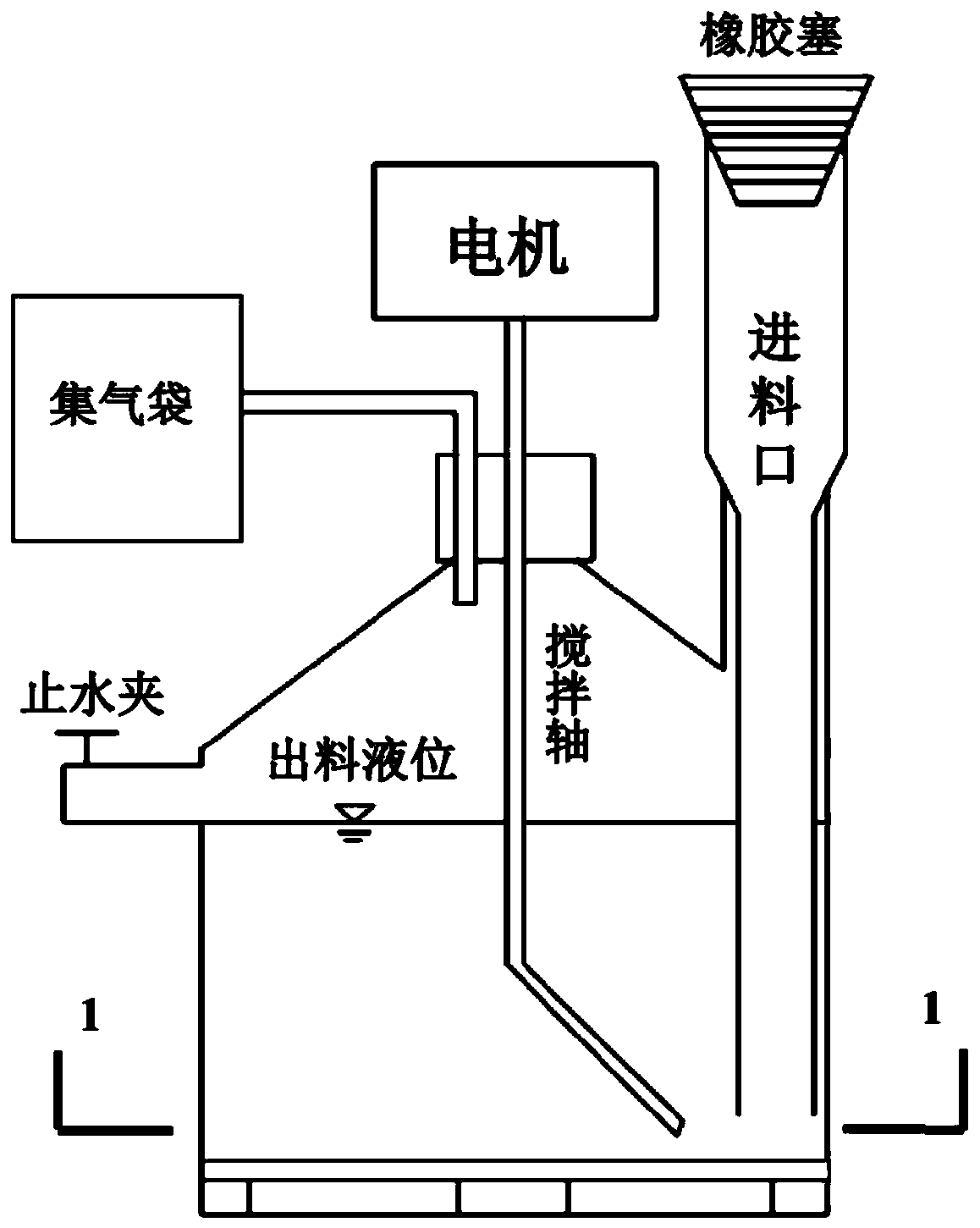

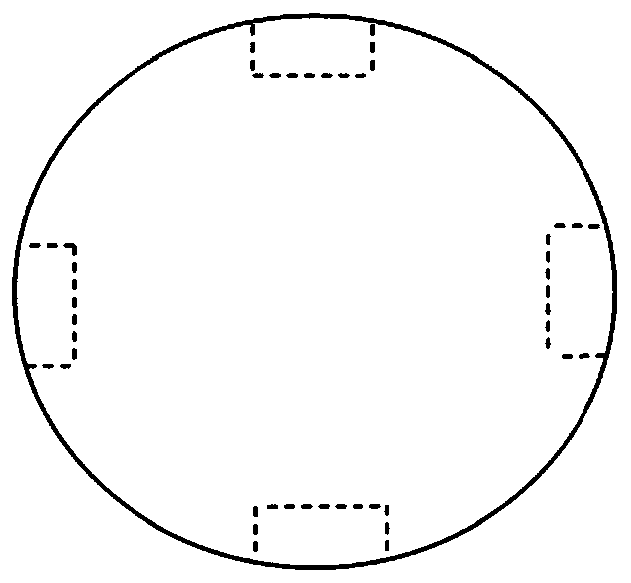

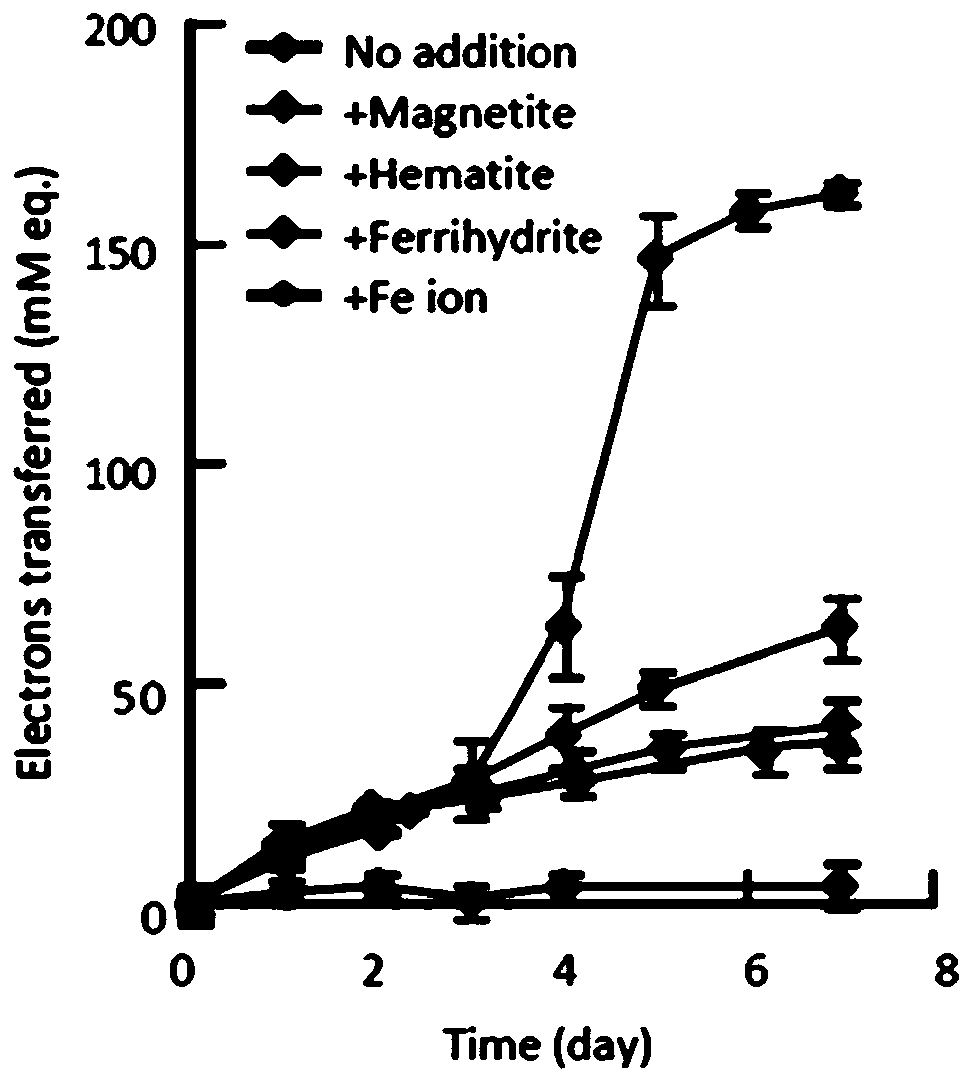

[0036] A method of enhanced anaerobic digestion of municipal sludge for methane production was implemented in batch methanogenesis experiments. Using the residual sludge of the secondary settling tank (VS=51.9%~70.8%, TS=1.8%~5.1%) as the substrate, the anaerobic digestion sludge in the reactor running stably (VS=35.6%~47.9%, TS= 2.5%~5.2%) as inoculum mud, and batch methanogenic experiments were carried out in 500mL serum bottles. For the experimental equipment, see figure 1 , figure 1 For the cross-sectional schematic diagram of the 1-1 section, see figure 2 ,From figure 2 It can be seen from the figure that in this embodiment, four brackets are arranged on the side wall of the serum bottle in the circumferential direction to support the filter screen structure (the shaded part in the figure), the feeding tube is inserted from the upper part of the serum bottle and the feeding port extends into the serum inside the bottle.

[0037] A filter structure with titanium mesh...

Embodiment 2

[0040] A method of enhanced anaerobic digestion of municipal sludge for methane production was implemented in a semi-continuous methane production experiment. Using sludge after gravity concentration (VS=51.9%~70.8%, TS=3.8%~5.1%) as the substrate, anaerobically digested sludge (VS=35.6%~47.9%, TS=2.5 %~5.2%) as inoculum slime, a semi-continuous methane production experiment was carried out in a reactor with a working volume of 2L.

[0041] The reactor of the experimental group was placed at the 0.5L position (near the feed inlet) with a filter structure with titanium mesh as the skeleton and ferric oxide as the coating, while the control group did not place the filter structure. Both the semi-continuous reactors of the experimental group and the control group were fed with 2L of inoculum mud first, with a daily feed of 200mL and a discharge of 200mL, SRT=10d. The reactor is heated by a water bath at 37-55 degrees, and the stirring is stopped for 1 minute every minute, and th...

Embodiment 3

[0044] Implementation of a method for enhanced anaerobic digestion of municipal sludge for methane production in continuous methane production experiments.

[0045] Using the residual sludge of the secondary settling tank (VS=51.9%~70.8%, TS=1.8%~5.1%) as the substrate, the anaerobic digestion sludge in the reactor running stably (VS=35.6%~47.9%, TS= 2.5%~5.2%) as inoculum slime, and the continuous methane production experiment was carried out in a reactor with a working volume of 4L.

[0046] The reactor of the experimental group was placed at the 0.8L position (close to the feed inlet) with a filter structure with titanium mesh as the skeleton and ferric oxide as the coating, while the control group did not place the filter structure. Both the semi-continuous reactors of the experimental group and the control group were fed with 4L inoculum mud first, and started by continuous feeding and discharging, SRT=20d. The reactor is heated by a water bath at 37-55 degrees, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com