Novel fog gun capable of realizing dry-fog dust suppression

A dry fog and dust fog technology, applied in liquid spray devices, dispersed particle separation, spray devices, etc., can solve the problems of large material humidification, excessive material humidity, large water consumption, etc., to reduce water consumption and prevent humidity. The effect of exceeding the standard and refining the fog particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

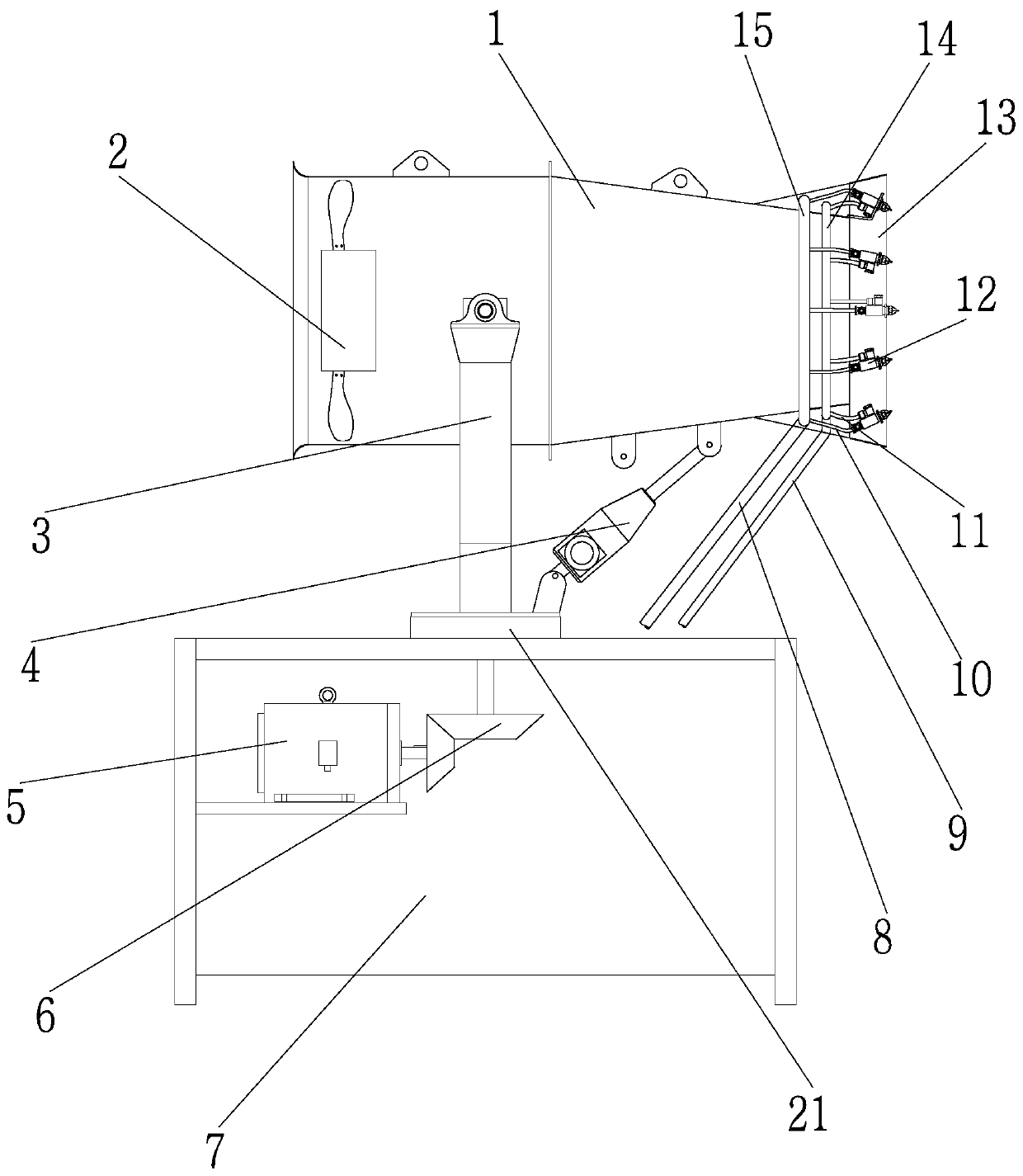

[0046] Please refer to Figure 1 to Figure 3 , a new type of dry fog dust suppressing fog cannon, including an air cylinder 1, a fan 2, a dry fog mechanism and an adjustment mechanism, one end of the air cylinder 1 is connected to the fan 2, and the fan 2 is arranged on the air cylinder 1 Inside, the other end of the air cylinder 1 is connected to the dry fog mechanism, and the air cylinder 1 is provided with the adjustment mechanism;

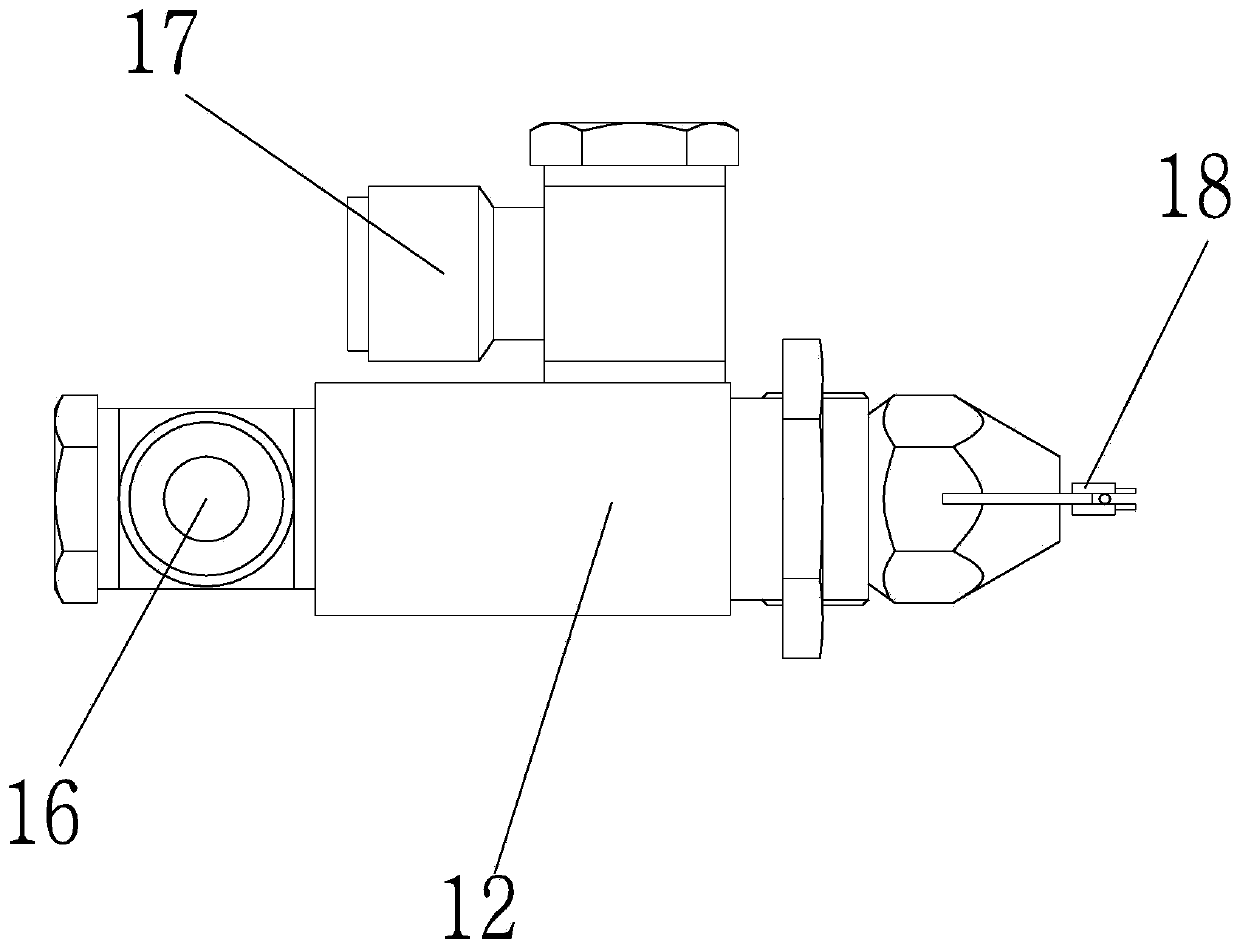

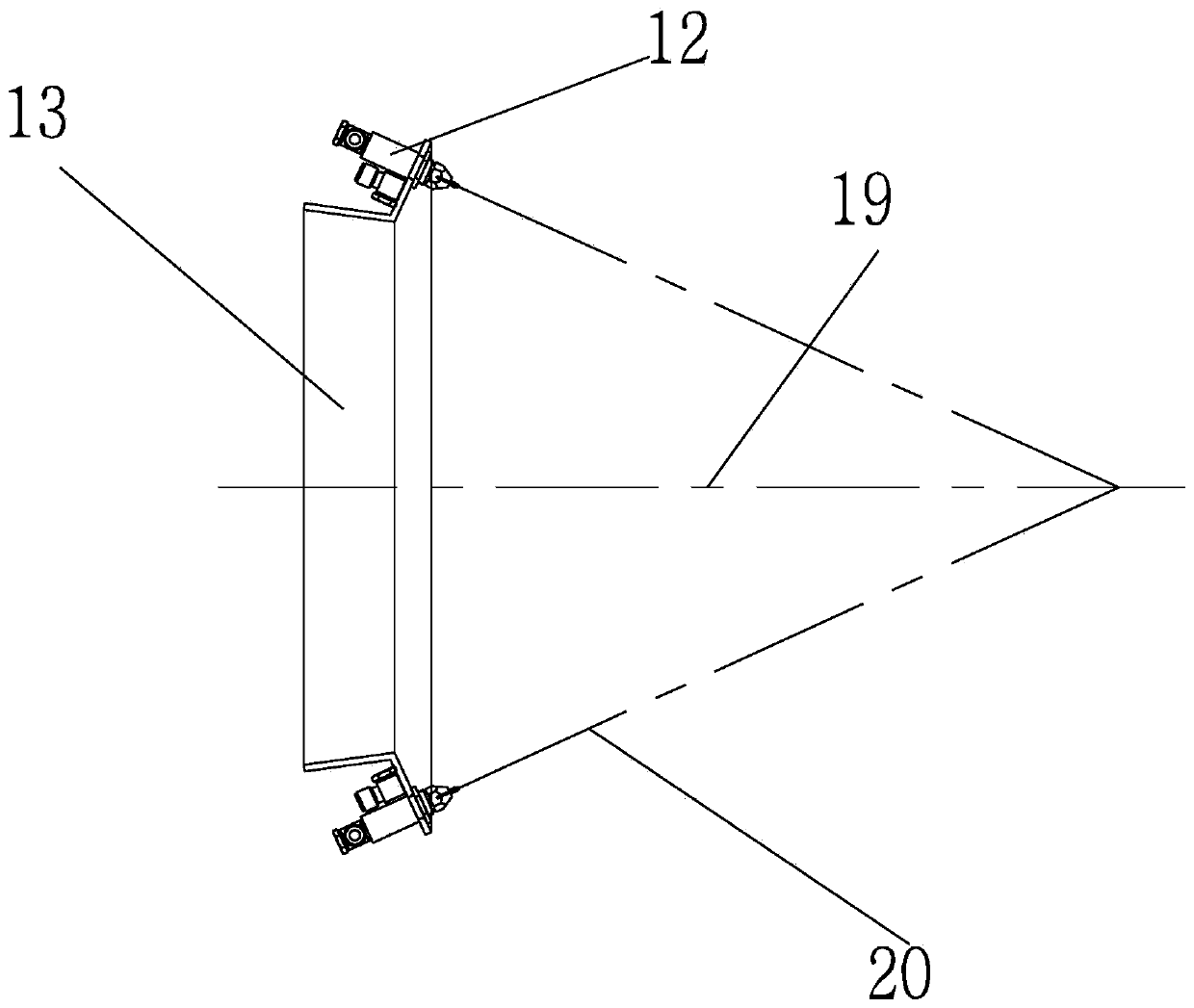

[0047] The dry fog mechanism includes a two-fluid assembly and a dry fog nozzle 12, the two-fluid assembly is arranged at the other end of the air cylinder 1, and several dry fog nozzles 12 are arranged on the two-fluid assembly. The dry mist nozzle 12 is fixedly connected with the other end of the air cylinder 1;

[0048] The two-fluid assembly includes a gas pipe 14 and a liquid pipe 15, and the gas pipe 14 and the liquid pipe 15 are arranged around the air cylinder 1, and the gas pipe 14 is connected to the dry mist nozzle through the air g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com