Vinyl chloride polymerization terminator with good low-temperature fluidity, preparation method and application thereof

A vinyl chloride polymerization and low-temperature fluidity technology, which is applied in the field of vinyl chloride polymerization terminators with good low-temperature fluidity, can solve the problems of consuming polymerization initiators and reducing the polymerization reaction rate, etc., and achieves improved thermal stability and good low-temperature fluidity , High aging whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

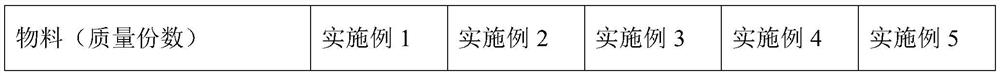

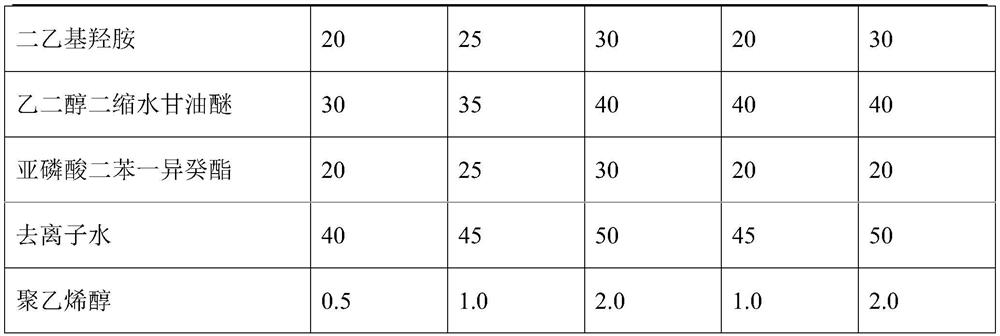

[0024] A vinyl chloride polymerization terminator with good low-temperature fluidity, the components and contents of Examples 1-5 are shown in Table 1.

[0025] Each material component was weighed according to the proportioning in Table 1. Mix 20-30g diethylhydroxylamine, 30-40g ethylene glycol diglycidyl ether, 20-30g diphenyl-isodecyl phosphite, 40-50g deionized water, 0.5-2g polymerization degree 350, alcoholysis degree 55% polyvinyl alcohol aqueous solution with a concentration of 5% was put into a glass beaker and stirred for 10 minutes, then added to a high-speed shear emulsifier and emulsified at a speed of 2000r / min for 30 minutes to obtain a uniform and stable low-temperature flow of each component. Good vinyl chloride polymerization terminator.

[0026] Table 1

[0027]

[0028]

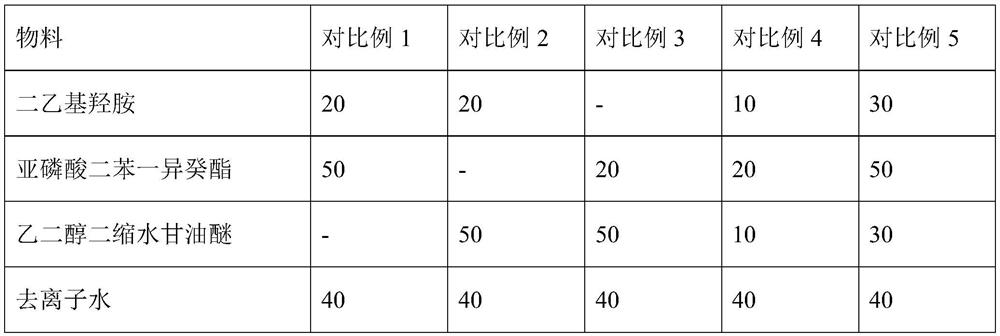

[0029] The vinyl chloride polymerization terminator with good low-temperature fluidity prepared in Examples 1-5 was used to terminate the vinyl chloride polymerization reaction.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com